The Importance of Fan Balancing in Industrial Equipment Maintenance

Được xuất bản bởi Nikolai Shelkovenko trên

Cân bằng quạt – Loại bỏ rung động và kéo dài tuổi thọ thiết bị

Hãy tưởng tượng một chiếc quạt công nghiệp tốc độ cao rung lắc dữ dội, bu lông bị lỏng sau mỗi vòng quay. Tình huống kinh hoàng này thường do rotor quạt bị mất cân bằng nhẹ. Rung động và tiếng ồn quá mức không chỉ gây phiền toái — chúng là dấu hiệu cảnh báo sự cố có thể dẫn đến thời gian ngừng hoạt động và sửa chữa tốn kém.

Fan balancing là quá trình hiệu chỉnh sự mất cân bằng này. Đây là một trong những quy trình được tìm kiếm nhiều nhất trong bảo trì thiết bị vì quạt rất nhạy cảm với bất kỳ sự phân bổ trọng lượng không đều nào. Ngay cả một độ lệch nhỏ nhất cũng có thể dẫn đến rung động đáng kể. Sự mất cân bằng xảy ra khi tâm hình học của trục quạt không thẳng hàng với trọng tâm của nó. Tốc độ quay của quạt càng cao, việc cân bằng chính xác càng trở nên quan trọng.

Ví dụ, chỉ cần một lực mất cân bằng 20 gram ở rìa cánh quạt lớn đang quay với tốc độ 3000 vòng/phút cũng có thể tạo ra lực ly tâm khoảng 900 N — tương đương với một quả tạ 90 kg đập vào ổ trục 50 lần mỗi giây. Không có gì ngạc nhiên khi nếu không được khắc phục, sự mất cân bằng này sẽ nhanh chóng gây ra hư hỏng.

Nguyên nhân nào gây ra hiện tượng quạt mất cân bằng?

The most common causes of fan imbalance include:

- Abrasive wear on fan blades

- Dirt accumulation on fan blades

- Lắp ráp lỏng lẻo hoặc không thẳng hàng cánh quạt trên trục

- Biến động nhiệt độ trong vỏ quạt hoặc trục quạt

- Mất trọng lượng cân bằng (đã thêm trước đó)

- Biến dạng lưỡi dao (uốn cong hoặc hư hỏng)

Tại sao cân bằng quạt lại quan trọng?

Vận hành quạt mất cân bằng sẽ gây ra rung động nguy hiểm cho toàn bộ kết cấu. Rung động quá mức dẫn đến tăng mức tiêu thụ năng lượng, tăng tốc độ hao mòn và thường làm hỏng sớm ổ trục (trên trục hoặc trong các kết cấu đỡ). Thậm chí có thể gây ra thời gian ngừng hoạt động ngoài dự kiến do hỏng hóc.

Mặt khác, một chiếc quạt cân bằng tốt sẽ:

- Chạy hiệu quả hơn (ít lãng phí năng lượng hơn)

- Giảm bớt áp lực lên các thành phần của nó

- Kéo dài tuổi thọ của vòng bi và các bộ phận khác

- Hoạt động êm hơn

Tóm lại, cho dù bạn đang lắp quạt mới hay bảo dưỡng quạt hiện có, bạn không bao giờ nên bỏ qua bước cân bằng trong quá trình bảo trì.

Important: Mặc dù mất cân bằng là nguyên nhân phổ biến nhất gây ra độ rung cao ở quạt, nhưng nó không phải là nguyên nhân duy nhất. Các vấn đề về cấu trúc, khe hở quá mức, vấn đề về truyền động đai, sai lệch, nứt rotor hoặc ổ trục bị lỗi cũng có thể tạo ra rung động. Điều quan trọng là phải có một chuyên gia chẩn đoán rung động giàu kinh nghiệm xác định nguyên nhân gốc rễ của bất kỳ sự gia tăng rung động nào trước khi cho rằng việc cân bằng sẽ khắc phục được vấn đề.

Bình luận của chuyên gia

Kinh nghiệm cho thấy, mọi người thường tìm đến dịch vụ cân bằng khi độ rung tăng cao. Tuy nhiên, cân bằng thực chất là bước cuối cùng trong việc giảm độ rung. Trước khi tiến hành bước này, cần phải xem xét kỹ lưỡng vibration diagnostic Cần phải tiến hành kiểm tra tình trạng thiết bị. Bất kỳ khiếm khuyết nào – chẳng hạn như lỗi khớp nối, trục không cân chỉnh hoặc kết cấu đỡ không đủ cứng – cần được xác định và khắc phục trước. Chỉ sau đó mới nên tiến hành cân bằng, nếu vẫn cần thiết.

Ví dụ, một khách hàng gần đây đã yêu cầu cân bằng quạt cho một máy sấy. Các phép đo độ rung của chúng tôi (cụ thể là phổ vận tốc rung) cho thấy sự hiện diện của tình trạng lỏng lẻo về mặt cơ học. Sau khi kiểm tra, chúng tôi phát hiện hư hỏng ở vị trí kết cấu đỡ quạt gắn vào nền móng. Sau khi cố định lại các giá đỡ và chẩn đoán lại, chúng tôi nhận thấy độ mất cân bằng còn lại nằm trong giới hạn cho phép. Trong trường hợp này, việc cân bằng không còn cần thiết nữa. Các vấn đề như nền móng lỏng lẻo hoặc sai lệch sẽ ngăn cản việc cân bằng thành công. Lưu ý, việc cân bằng chỉ nên được thực hiện trên máy móc có tình trạng cơ học tốt.

Cách thực hiện cân bằng quạt

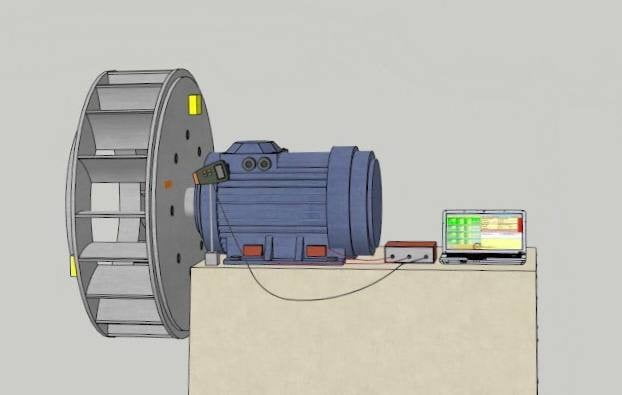

Các chuyên gia của chúng tôi thường thực hiện fan balancing (cân bằng cánh quạt hoặc toàn bộ bánh xe quạt) tại chỗ sử dụng ổ trục riêng của quạt. Phương pháp tại chỗ này cho phép đạt được độ chính xác và tốc độ tối đa mà không cần tháo rời, tránh can thiệp không cần thiết vào cấu trúc của thiết bị.

Trong mọi công việc cân bằng, chúng tôi hướng tới mức mất cân bằng còn lại thấp nhất có thể và tuân thủ các tiêu chuẩn chất lượng cân bằng của ISO 1940-1-2007 cho loại thiết bị phù hợp. Để đạt được điều này, chúng tôi sử dụng một thiết bị cân bằng động di động — máy phân tích rung động Balanset-1A.

Steps Involved:

Quá trình cân bằng bao gồm nhiều giai đoạn. Số lượng cảm biến được sử dụng và vị trí lắp đặt có thể do nhà sản xuất quạt chỉ định. Hướng dẫn chung khuyến nghị lắp đặt cảm biến trên ổ trục quạt và trên vỏ quạt. Nếu không thể thực hiện được do hạn chế về thiết kế, thì nên lắp đặt cảm biến ở vị trí càng gần ổ trục càng tốt.

- Lắp đặt cảm biến rung vuông góc với trục quay của rôto.

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan's impeller. Balanset-1 Vibromera - Mount the tachometer on the magnetic stand.

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan's impeller. Balanset-1 Vibromera - Stick reflective tape on the pulley and point the RPM sensor toward the tape.

- Kết nối cảm biến rung với thiết bị cân bằng và kết nối thiết bị với máy tính xách tay.

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan's impeller. Balanset-1 Vibromera - Khởi động phần mềm cân bằng trên máy tính xách tay.

- Chọn chế độ cân bằng hai mặt phẳng.

Phần mềm cho thiết bị cân bằng di động và máy phân tích độ rung Balanset-1A – Màn hình Menu chính. - Nhập mã nhận dạng rôto (tên hoặc số) và vị trí của rôto.

- Cân vật thử nghiệm và nhập giá trị của nó cùng bán kính mà vật sẽ được lắp đặt.

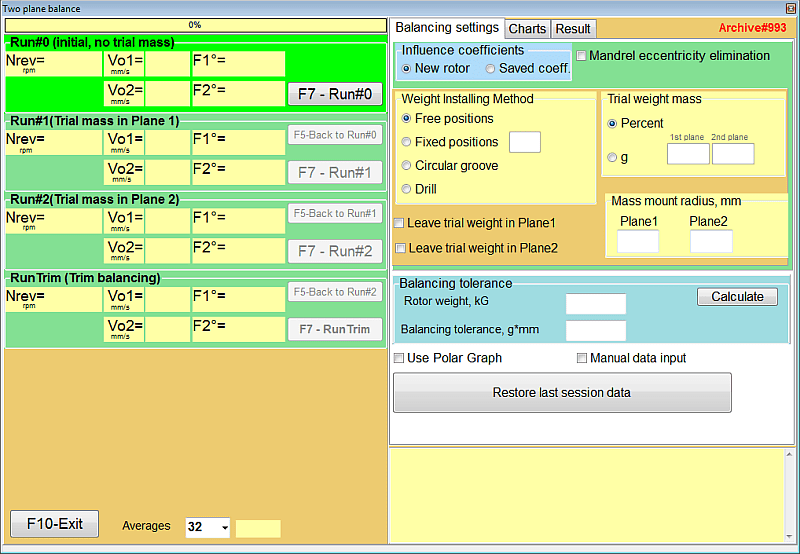

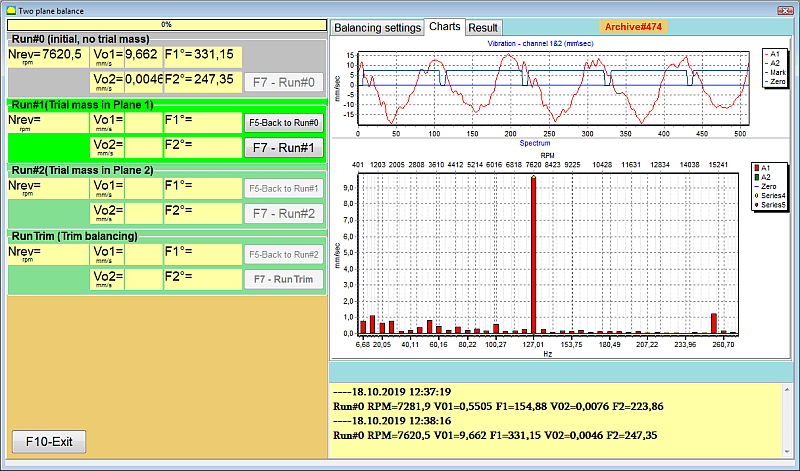

Phần mềm cho thiết bị cân bằng di động và máy phân tích rung động Balanset-1A – Thiết lập các thông số cân bằng động. - Chạy quạt (rôto) và đo mức rung ban đầu (mức cơ sở).

Phần mềm cho máy cân bằng di động và máy phân tích độ rung Balanset-1A – Cửa sổ cân bằng hai mặt phẳng hiển thị độ rung ban đầu. - Lắp quả nặng thử vào mặt phẳng hiệu chỉnh đầu tiên trên rôto của quạt.

- Chạy lại quạt và đo độ rung lần thứ hai.

- Xác minh rằng biên độ hoặc pha rung động đã thay đổi ít nhất 20% (chỉ ra rằng trọng lượng thử nghiệm có tác động có thể đo lường được).

- Tháo quả nặng thử nghiệm ra khỏi mặt phẳng đầu tiên và lắp vào mặt phẳng thứ hai của rôto.

- Chạy quạt một lần nữa và đo độ rung lần thứ ba.

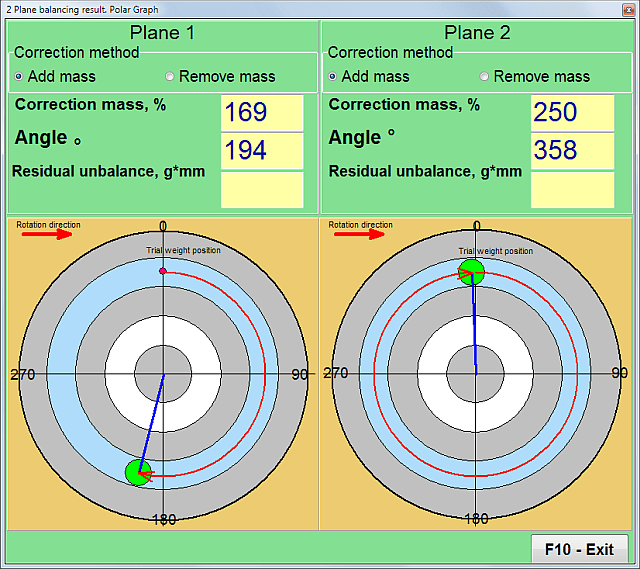

- Sau đó, phần mềm sẽ tính toán trọng số hiệu chỉnh cần thiết và góc đặt chúng trên mặt phẳng thứ nhất và thứ hai.

Phần mềm cho thiết bị cân bằng di động và máy phân tích độ rung Balanset-1A – Kết quả cân bằng hai mặt phẳng (biểu đồ cực chỉ ra nơi cần thêm trọng lượng). - Remove the test weight from the rotor.

- Chuẩn bị trọng lượng hiệu chỉnh cố định của khối lượng đã chỉ định (theo tính toán).

- Gắn hoặc hàn trọng lượng hiệu chỉnh vào rôto tại các vị trí đã chỉ định.

máy cân bằng động di động, máy phân tích rung động "Balanset-1A" - Chạy lại quạt và xác minh rằng quá trình cân bằng đã thành công (mức độ rung hiện nằm trong giới hạn cho phép).

- Nếu phần mềm gợi ý thêm những điều chỉnh nhỏ, hãy thêm trọng lượng theo khuyến nghị và kiểm tra lại độ cân bằng cho đến khi độ rung giảm thiểu.

Bằng cách thực hiện quy trình này, chúng tôi đảm bảo độ chính xác cao trong việc cân bằng quạt, góp phần vào hiệu quả và độ tin cậy lâu dài cho thiết bị công nghiệp của bạn.

Conclusion

Việc cân bằng quạt đúng cách sẽ loại bỏ một trong những nguồn rung động chính của máy móc. Kết quả là thiết bị của bạn hoạt động mượt mà và đáng tin cậy hơn. Việc bỏ qua bước này có thể dẫn đến những hư hỏng tốn kém, trong khi việc cân bằng thường xuyên (sau khi khắc phục bất kỳ sự cố cơ học tiềm ẩn nào) sẽ giúp bạn tiết kiệm thời gian và tiền bạc về lâu dài. Đừng chờ đợi để quạt tự rung — hãy đưa việc cân bằng vào chương trình bảo trì thường xuyên để bảo vệ máy móc và giữ cho máy hoạt động ở mức tối ưu.

Những câu hỏi thường gặp

Nguyên nhân nào gây ra sự mất cân bằng của quạt?

Sự mất cân bằng của quạt thường do sự phân bổ khối lượng không đều giữa các bộ phận quay. Các nguyên nhân phổ biến bao gồm mài mòn trên cánh quạt, bụi bẩn tích tụ trên cánh quạt, cánh quạt bị lỏng hoặc lệch, biến động nhiệt độ gây ra sự giãn nở hoặc co lại của vật liệu, mất các khối cân bằng đã lắp đặt trước đó, hoặc biến dạng vật lý của cánh quạt.

Tại sao việc cân bằng quạt lại quan trọng?

Quạt mất cân bằng sẽ tạo ra độ rung quá mức, có thể làm hỏng quạt và các thiết bị được kết nối. Việc cân bằng quạt sẽ giảm thiểu độ rung này, tránh lãng phí năng lượng và giảm thiểu áp lực lên ổ trục và các bộ phận khác. Quạt được cân bằng đúng cách cũng hoạt động êm ái và hiệu quả hơn, giúp kéo dài tuổi thọ của thiết bị.

Làm thế nào để cân bằng quạt?

Cân bằng quạt được thực hiện bằng cách thêm hoặc bớt trọng lượng trên rotor (cánh quạt) của quạt để điều chỉnh bất kỳ sự mất cân bằng khối lượng nào. Quy trình chung bao gồm đo độ rung của quạt, xác định vị trí mất cân bằng, sau đó gắn các quả cân hiệu chỉnh nhỏ vào các vị trí cụ thể trên rotor để cân bằng lại. Các máy cân bằng di động hiện đại sử dụng cảm biến và phần mềm để hướng dẫn quy trình này và tính toán chính xác trọng lượng và vị trí cần thiết. (Xem quy trình từng bước ở trên để biết chi tiết.)

Khi nào cần cân bằng quạt công nghiệp?

Quạt công nghiệp nên được cân bằng bất cứ khi nào bạn nhận thấy độ rung quá mức hoặc sau bất kỳ công việc sửa chữa/bảo trì nào có thể làm mất cân bằng quạt (chẳng hạn như thay thế hoặc hàn cánh quạt). Quạt mới thường được nhà sản xuất cân bằng tốt, nhưng theo thời gian, sự hao mòn và tích tụ vật liệu có thể gây mất cân bằng. Việc kiểm tra định kỳ mức độ rung động trong quá trình bảo trì là một biện pháp tốt và nên thực hiện cân bằng nếu mức độ rung động vượt quá giới hạn khuyến nghị.

Có thể cân bằng quạt tại chỗ được không?

Có. Việc cân bằng quạt thường có thể được thực hiện tại chỗ (in situ) bằng thiết bị cân bằng di động. Cân bằng tại chỗ, giống như dịch vụ được mô tả ở trên, sử dụng ổ trục riêng của quạt và không cần tháo rời máy. Điều này giúp tiết kiệm thời gian và đảm bảo quạt được cân bằng trong điều kiện hoạt động bình thường.