Balancing of a Fan Impeller at a Repair Plant

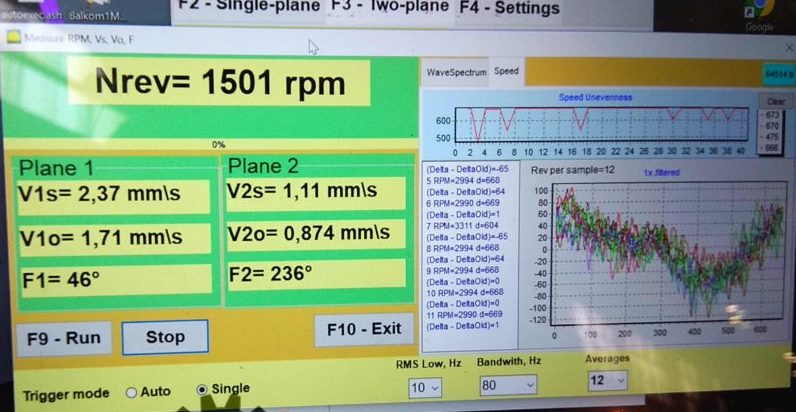

At a repair facility, the task at hand was the balancing of a fan impeller. Utilizing the Balanset-1A dynamic rotor balancing device, the process was initiated with the measurement of the initial vibration. Following the established procedure:

- The initial vibration was measured.

- Calibration or test weights were set up. The Balanset-1A device accurately gauged the variation in vibration with a weight of known mass at a specified point.

- Based on the data obtained, corrective weights were affixed or mass was removed. The device precisely calculated the angle and weight needed to balance the rotor.

- The results were then verified.

The outcome was impressive. After balancing, the vibration values were reduced significantly to 1.7 mm/s and 0.8 mm/s respectively, ensuring the fan impeller's efficient operation. Such an achievement, facilitated by the Balanset-1A, showcases its prowess in क्षेत्र संतुलन and vibration analysis.