فاریسٹ ملچر روٹر بیلنسنگ: موثر آپریشن کی کلید

فاریسٹ ملچرز طاقتور مشینیں ہیں جو پودوں کو ٹکڑے ٹکڑے کرنے اور آگ کے توڑنے کے لیے بنائی گئی ہیں۔ ملچر کے مرکز میں خاص چھریوں یا دانتوں سے لیس روٹر ہے، جو درختوں اور جھاڑیوں کو پیسنے کے لیے تیز رفتاری سے گھومتا ہے۔ تاہم، شدید استعمال اور بیرونی عوامل کی وجہ سے، روٹر غیر متوازن ہو سکتا ہے، جس کی وجہ سے کمپن ہوتی ہے۔

عدم توازن کیا ہے؟

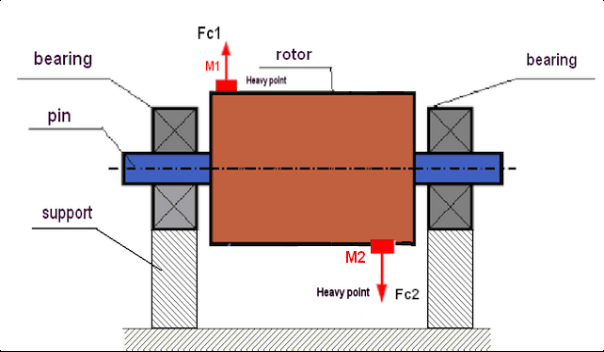

عدم توازن ایک ایسی حالت ہے جہاں روٹر کا ماس اس کے گردش کے محور کے مقابلہ میں غیر مساوی طور پر تقسیم ہوتا ہے۔ اس کے نتیجے میں سینٹرفیوگل قوتیں پیدا ہوتی ہیں جو ناپسندیدہ کمپن کا باعث بنتی ہیں۔ وائبریشن، بدلے میں، تیز بیئرنگ پہننے، ملچر کے دیگر اجزاء کو نقصان، کارکردگی میں کمی، اور یہاں تک کہ خرابی کا باعث بن سکتی ہے۔

عدم توازن کی دو اہم اقسام ہیں: جامد اور متحرک۔

جامد عدم توازن

جامد عدم توازن اس وقت ہوتا ہے جب روٹر کی کشش ثقل کا مرکز اس کے گردش کے محور سے دور ہوتا ہے۔ اس کی وجہ سے روٹر ایک ایسی پوزیشن تلاش کرتا ہے جہاں اس کا بھاری حصہ نیچے ہو۔ جامد عدم توازن کا پتہ چلا جاسکتا ہے یہاں تک کہ جب روٹر گھوم رہا ہو۔

متحرک عدم توازن

متحرک عدم توازن روٹر کی لمبائی کے ساتھ ناہموار بڑے پیمانے پر تقسیم سے پیدا ہوتا ہے۔ اس صورت میں، گردش کے دوران قوتیں اور لمحات پیدا ہوتے ہیں، اضافی کمپن کا باعث بنتے ہیں۔ متحرک عدم توازن صرف اس وقت ظاہر ہوتا ہے جب روٹر گھوم رہا ہو۔

آپ آلات کے بغیر متحرک عدم توازن کو کیوں درست نہیں کر سکتے؟

بہت سے مکینکس اور آپریٹرز خصوصی آلات استعمال کیے بغیر روٹر پر وزن ڈال کر یا ہٹا کر عدم توازن کو "آنکھ سے" درست کرنے کی کوشش کرتے ہیں۔ تاہم، یہ نقطہ نظر صرف جامد عدم توازن کے لیے موثر ہے۔ متحرک عدم توازن کے ساتھ، جہاں بھاری پوائنٹس روٹر کے مختلف طیاروں میں ہوتے ہیں، ان کے مقام اور ضروری بڑے پیمانے پر اصلاح کا بصری طور پر تعین کرنا تقریباً ناممکن ہے۔

متحرک عدم توازن کو ختم کرنے کے لیے، خصوصی آلات کی ضرورت ہے - پورٹیبل بیلنسرز جو کمپن کے طول و عرض اور مرحلے کی درست پیمائش کر سکتے ہیں، اور ضروری اصلاحی وزن اور ان کی تنصیب کے مقامات کا حساب لگا سکتے ہیں۔

بڑھی ہوئی وائبریشن کے نقصانات

روٹر کمپن میں اضافہ کئی منفی نتائج کا باعث بن سکتا ہے:

- بیرنگ، شافٹ، ہاؤسنگ، اور دیگر اجزاء کا تیز لباس

- ہائیڈرولک سسٹم اور ٹریکٹر کے انجن کو نقصان

- پیداواری صلاحیت میں کمی اور ایندھن کی کھپت میں اضافہ

- آپریٹر کے لیے کام کرنے کے خراب حالات، تھکاوٹ میں اضافہ، اور پیشہ ورانہ بیماریوں کا خطرہ

- حادثات کا خطرہ بڑھ گیا۔

فیلڈ بیلنسنگ: وقت اور پیسے کی بچت

پورٹیبل بیلنسر کا استعمال کرتے ہوئے ملچر روٹر کی فیلڈ بیلنسنگ ایک مؤثر حل ہے جو سامان کو جدا کرنے، نقل و حمل اور دوبارہ جوڑنے کے مہنگے عمل سے بچتا ہے۔ آپ عدم توازن کو فوری طور پر ختم کر سکتے ہیں اور کام کو دوبارہ شروع کر سکتے ہیں، ڈاؤن ٹائم کو کم کر کے اور وقت اور پیسے کی بچت کر سکتے ہیں۔

Balanset-1A کے ساتھ مرحلہ وار توازن کا عمل

- تیاری: روٹر بیرنگ کے قریب ملچر ہاؤسنگ میں وائبریشن سینسر منسلک کریں۔ سینسرز کو روٹر کی گردش کے محور پر کھڑا ہونا چاہیے۔ روٹر یا گھرنی کے ساتھ ایک عکاس مارکر منسلک کریں۔ ٹیکومیٹر کو مقناطیسی اسٹینڈ پر لگائیں تاکہ اس کی لیزر بیم عکاس مارکر سے ٹکرائے۔ سینسرز کو "Balanset-1A" ڈیوائس سے جوڑیں، جو بدلے میں ایک لیپ ٹاپ سے جڑ جاتا ہے۔ خصوصی بیلنسنگ سافٹ ویئر لانچ کریں۔

- ابتدائی پیمائش: سافٹ ویئر میں دو ہوائی جہاز بیلنسنگ موڈ کو منتخب کریں۔ انشانکن وزن کا وزن کریں اور اس کا وزن اور تنصیب کا رداس پروگرام میں داخل کریں۔ ملچر روٹر شروع کریں اور ابتدائی کمپن کی سطح کی پیمائش کریں۔

- پہلے جہاز میں توازن: پہلے درست کرنے والے جہاز میں روٹر پر کیلیبریشن وزن انسٹال کریں (عام طور پر بیرنگ میں سے ایک کے قریب)۔ روٹر کو دوبارہ شروع کریں اور کمپن کی پیمائش کریں۔ یقینی بنائیں کہ کمپن یا فیز کی تبدیلیاں کم از کم 20% ہیں۔

- دوسرے جہاز میں توازن: انشانکن وزن کو دوسرے درست کرنے والے طیارے میں منتقل کریں (عام طور پر دوسرے بیئرنگ کے قریب) اور گردش کے دوران تھرڈ وائبریشن کی پیمائش کریں۔

- ڈیٹا تجزیہ: حاصل کردہ ڈیٹا کا استعمال کرتے ہوئے، روٹر کو متوازن کرنے کے لیے اصلاحی وزن اور ان کی تنصیب کے مقامات کا تعین کریں۔

- اصلاحی وزن کی تنصیب: پروگرام کی طرف سے بتائی گئی جگہوں پر روٹر پر اصلاحی وزن انسٹال کریں۔

- تصدیق: وزن نصب کرنے کے بعد کمپن کی سطح کی پیمائش کریں اور اس بات کو یقینی بنائیں کہ کمپن قابل قبول سطح تک کم ہو جائے۔ اگر ضروری ہو تو، اصلاحی وزن کا کچھ حصہ شامل کریں یا ہٹائیں اور توازن کو دوبارہ چیک کریں۔

Balanset-1A: روٹر بیلنسنگ میں آپ کا قابل اعتماد پارٹنر

"Balanset-1A" ایک پورٹیبل بیلنسر اور وائبریشن اینالائزر ہے، جو مختلف اقسام اور سائز کے روٹرز کو متوازن کرنے کے لیے بہترین ہے، بشمول فاریسٹ ملچر روٹرز۔

Balanset-1A کے اہم فوائد:

- Ease of Use: Balanset-1A سیکھنے اور استعمال کرنے میں آسان ہے، یہاں تک کہ ان لوگوں کے لیے بھی جو کمپن میں خصوصی علم نہیں رکھتے ہیں۔

- پورٹیبلٹی: کومپیکٹ اور ہلکا پھلکا، آلہ نقل و حمل اور سائٹ پر استعمال میں آسان ہے۔

- اعلی درستگی: Balanset-1A اعلی پیمائش کی درستگی فراہم کرتا ہے، معیار کے توازن کو یقینی بناتا ہے۔

- کثیر فعلیت: ڈیوائس کو نہ صرف توازن کے لیے استعمال کیا جا سکتا ہے بلکہ کمپن کے تجزیہ اور آلات کی تشخیص کے لیے بھی استعمال کیا جا سکتا ہے۔

- سستی قیمت: Balanset-1A پیسے کے لیے بہترین قیمت پیش کرتا ہے، جو کہ پیشہ ورانہ توازن کو صارفین کی ایک وسیع رینج کے لیے قابل رسائی بناتا ہے۔

Technical Specifications:

- RMS کمپن کی رفتار کی پیمائش کی حد: 0.02 سے 80 ملی میٹر فی سیکنڈ

- RMS کمپن کی رفتار کی پیمائش کی فریکوئینسی رینج: 5 سے 550 ہرٹز

- تصحیح طیاروں کی تعداد: 1 یا 2

- گردشی رفتار کی پیمائش کی حد: 100 سے 100,000 RPM

- کمپن فیز شفٹ پیمائش کی حد: 0 سے 360 ڈگری

- کمپن فیز شفٹ کی قابل اجازت مطلق پیمائش کی غلطی کی حدود: ±1 ڈگری

پیکیج کا مواد:

- USB انٹرفیس بلاک

- دو کمپن سینسر

- آپٹیکل سینسر (لیزر ٹیکومیٹر) مقناطیسی اسٹینڈ کے ساتھ

- Scale

- Software

- پلاسٹک لے جانے والا کیس

وارنٹی: 1 سال

Balanset-1A استعمال کرنے کے فوائد:

- وقت اور پیسے کی بچت: روٹر کا فیلڈ بیلنسنگ ڈاؤن ٹائم سے بچنے میں مدد کرتا ہے اور نقل و حمل اور مرمت کے اخراجات کو کم کرتا ہے۔

- پیداواری صلاحیت میں اضافہ: ایک متوازن روٹر زیادہ مؤثر طریقے سے کام کرتا ہے، اعلی ملچر کی کارکردگی کو یقینی بناتا ہے۔

- توسیع شدہ عمر: توازن ملچر کے اجزاء پر بوجھ کو کم کرتا ہے، ان کی عمر کو بڑھاتا ہے۔

- بہتر آپریٹر کے حالات: کم کمپن آپریٹر کے کام کو زیادہ آرام دہ اور محفوظ بناتی ہے۔

Conclusion

فارسٹ ملچر روٹر کو متوازن کرنا ایک اہم طریقہ کار ہے جو اس کے موثر اور محفوظ آپریشن کو یقینی بناتا ہے اور آلات کی عمر کو بڑھاتا ہے۔ باقاعدگی سے توازن سنگین مسائل کو روکتا ہے اور مرمت اور دیکھ بھال کے اخراجات کو کم کرتا ہے۔

باقاعدہ توازن کی اہمیت

ملچر روٹر کو باقاعدگی سے متوازن رکھنے کی سفارش کی جاتی ہے، خاص طور پر شدید استعمال کے بعد یا جب عدم توازن کی علامات، جیسے بڑھی ہوئی کمپن یا شور، ظاہر ہو۔ یہ ملچر کو بہترین حالت میں رکھنے میں مدد کرتا ہے اور مہنگے ٹوٹنے سے بچاتا ہے۔

Balanset-1A استعمال کرنے کی سفارشات

- مناسب سینسر کی تنصیب: اس بات کو یقینی بنائیں کہ وائبریشن سینسر محفوظ طریقے سے نصب ہیں اور درست طریقے سے مبنی ہیں۔

- درست وزن اور رداس کی پیمائش: انشانکن اور اصلاحی وزن کی درست پیمائش کے لیے ترازو کا استعمال کریں۔

- حفاظتی احتیاطی تدابیر: ملچر کے ساتھ کام کرتے وقت ہمیشہ حفاظتی اصولوں پر عمل کریں۔

- باقاعدگی سے توازن کی جانچ: وقتاً فوقتاً روٹر کے توازن کو چیک کریں، خاص طور پر شدید استعمال یا اجزاء کی تبدیلی کے بعد۔

پورٹیبل بیلنسر اور وائبریشن اینالائزر "Balanset-1A" کے ساتھ، آپ اپنی مشین کی کارکردگی اور وشوسنییتا کو بہتر بناتے ہوئے وقت اور پیسے کی بچت کرتے ہوئے، سائٹ پر موجود روٹر کو آسانی سے اور تیزی سے متوازن کر سکتے ہیں۔ توازن کو ملتوی نہ کریں – آج ہی اپنے سامان کا خیال رکھیں!

0 تبصرے