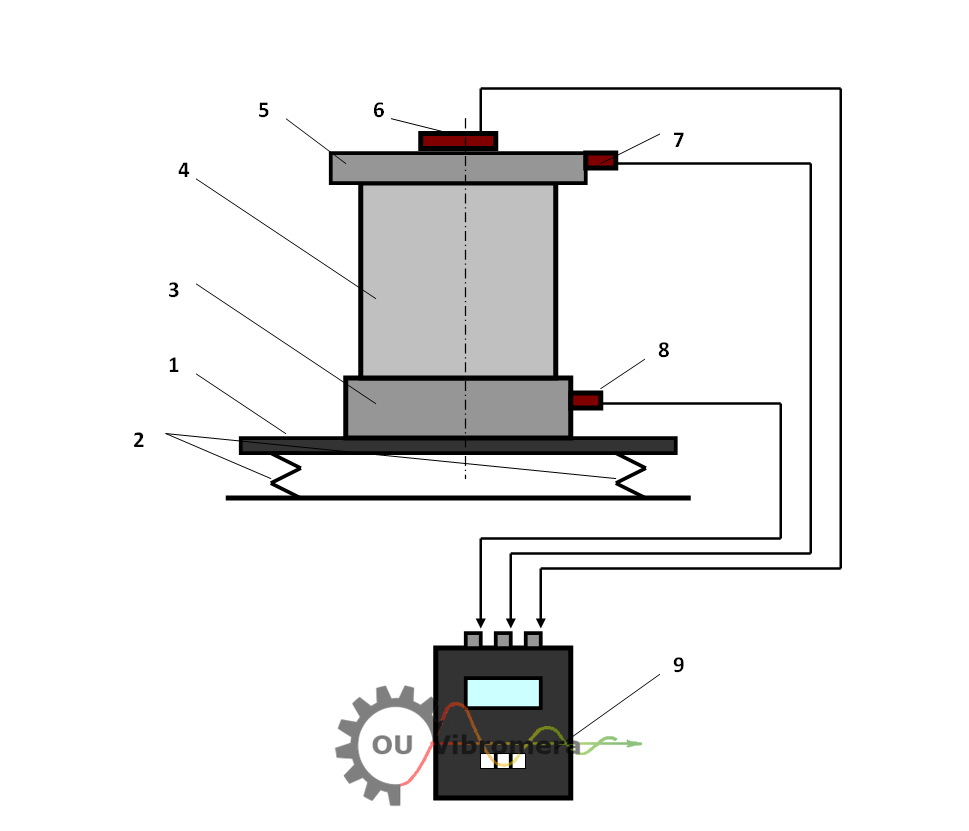

Assembled vacuum pumps rotors balancing

Introduction

At the factory, with our assistance, stands have been developed and implemented for the balancing of assembled rotors in high-speed vacuum pumps. These rotors must meet stringent quality requirements for balancing, adhering to the first-class standards as per GOST 22061-76, given that their operating frequency ranges from 42,000 to 60,000 RPM.

Technological Process

- First Stage: At this stage, when the rotation speed of the rotor does not exceed 8,000 RPM and the rotor remains rigid, the primary components of its force and torque imbalances are compensated for. With our devices, a stable residual vibration level below 0.01 mm/s is consistently achieved within a frequency range of 3,500 to 8,000 RPM.

- Second Stage: Subsequent balancing of the rotor is performed at the working frequency, which can reach either 42,000 or 60,000 RPM, depending on the pump design. At this frequency, which exceeds the critical rotation speed, the rotor becomes flexible and deforms, requiring additional balancing measures.

Results

The residual vibration of the rotor, ultimately achieved in the second stage, does not exceed 0.3 mm/s. This ensures a long period of trouble-free operation for this critical component. The total time for the balancing process of this unique product usually does not exceed 30 minutes.

Economic Efficiency

The cost for one of the balancing stands, equipped with our balancing device, was only $3,000 for the customer. This is approximately 10 times cheaper than the cost of a proposed imported alternative.