Centrifuges are indispensable equipment in many industries, from medicine to the chemical industry. They are used to separate liquid mixtures based on the density difference of the components. However, like any rotating equipment, centrifuges are prone to vibration, which can lead to a number of problems.

What is Vibration?

Vibration is the oscillatory motion that occurs when the rotor of a centrifuge rotates. It can be caused by various factors, such as:

- Rotor imbalance: uneven distribution of mass across the rotor.

- Rotor deformations: bends, warps.

- Bearing play: wear, improper installation.

- Asymmetry of rotor elements: improper shape, hole placement.

- External influences: uneven mounting, resonance phenomena.

Static and Moment Imbalance

There are two main types of imbalance: static and moment.

- Static imbalance of the centrifuge: occurs when the center of mass of the rotor does not coincide with its geometric axis. In this case, the rotor, being stationary, tends to tip over.

- Moment imbalance of the centrifuge: occurs when the center of mass of the rotor does not coincide with its axis of rotation. In this case, the rotor, being in motion, experiences a torque that causes it to “waggle.”

What is Balancing?

Balancing is the process of adjusting the mass distribution of the rotor to eliminate imbalance and minimize vibration. It can be static or dynamic.

- Static balancing: used to eliminate static imbalance. The rotor is placed on horizontal guides, and balancing weights are added to its lower part until it stops swaying.

- Dynamic balancing: used to eliminate both static and moment imbalances. The rotor is rotated, and special sensors measure its vibration. Based on this data, the location and mass of the balancing weights are calculated, which are then added to the rotor.

Problems Caused by Increased Vibration in a Centrifuge

Increased vibration in a centrifuge can lead to a number of problems, such as:

- Accelerated wear: vibration leads to friction and wear of bearings, shafts, seals, and other centrifuge components, reducing its service life.

- Reduced accuracy: vibration can affect the accuracy of component separation in the mixture, reducing the quality of the final product.

- Increased noise level: vibration can create unpleasant noise, which negatively affects the working conditions of the operators.

- Risk of destruction: in particularly severe cases, vibration can lead to the destruction of the centrifuge, posing a danger to people and the environment.

Balanset-1A: Your Reliable Assistant in Centrifuge Balancing

The Balanset-1A is a portable device for dynamic rotor balancing, which can be used to balance centrifuges of various types. It is easy to use and allows for high-precision balancing.

How to Balance a Centrifuge Using the Balanset-1A Device

Before directly proceeding with rotor balancing, a series of checks must be conducted to ensure that the mechanism is ready for this procedure.

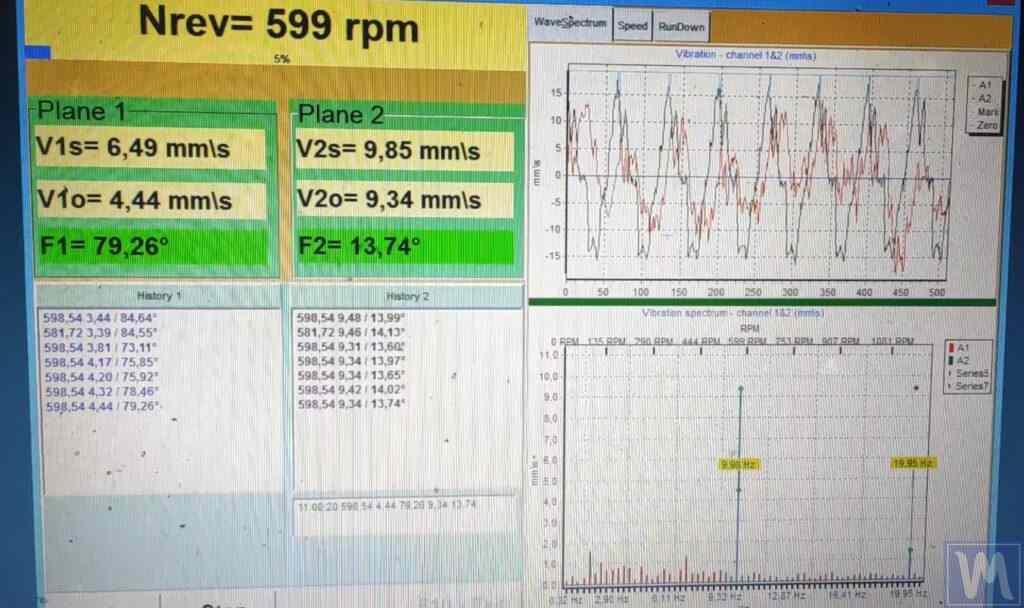

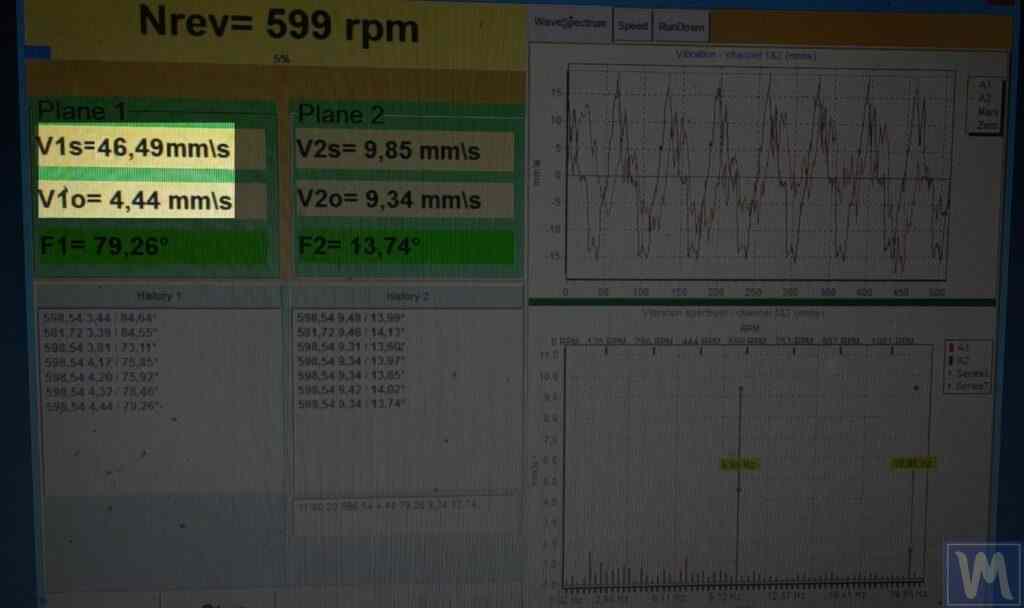

- Vibration Measurement in Vibrometer Mode: The first step is to measure the rotor’s vibration in vibrometer mode.

- Analysis of the Ratio Between Total and Rotational Vibration Components:

Compare the magnitude of the total vibration with the rotational component. If the total vibration approximately equals the rotational one, it indicates that the main contribution to the mechanism’s vibration is due to rotor imbalance. In this case, you can proceed to rotor balancing. If the total vibration significantly exceeds the rotational, this may indicate the presence of other problems not related to imbalance.

- Mechanism Inspection: If the total vibration significantly exceeds the rotational, a mechanism inspection is necessary.

- Bearing Inspection: Check the condition of the bearings, their wear, and the presence of play.

- Mounting Reliability: Verify the reliability of the mechanism’s mounting on the foundation, ensuring there are no gaps or plays at the attachment points.

- Rotor Interference: Ensure that the rotor does not interfere with stationary parts during rotation.

- Stability of Readings: Pay attention to the stability of readings in vibrometer mode. During normal operation, the amplitude and phase of vibration should not change by more than 10-15% during measurement.

- Preparation for Balancing: If no other problems were identified during the inspection, you can proceed to rotor balancing.

Important: Before balancing, thoroughly clean the rotor from dirt, dust, and grease to ensure accuracy of measurements.

By following these recommendations, you can:

- Ensure that the mechanism is ready for balancing.

- Identify and eliminate potential problems not related to imbalance.

- Ensure the accuracy and efficiency of balancing work.

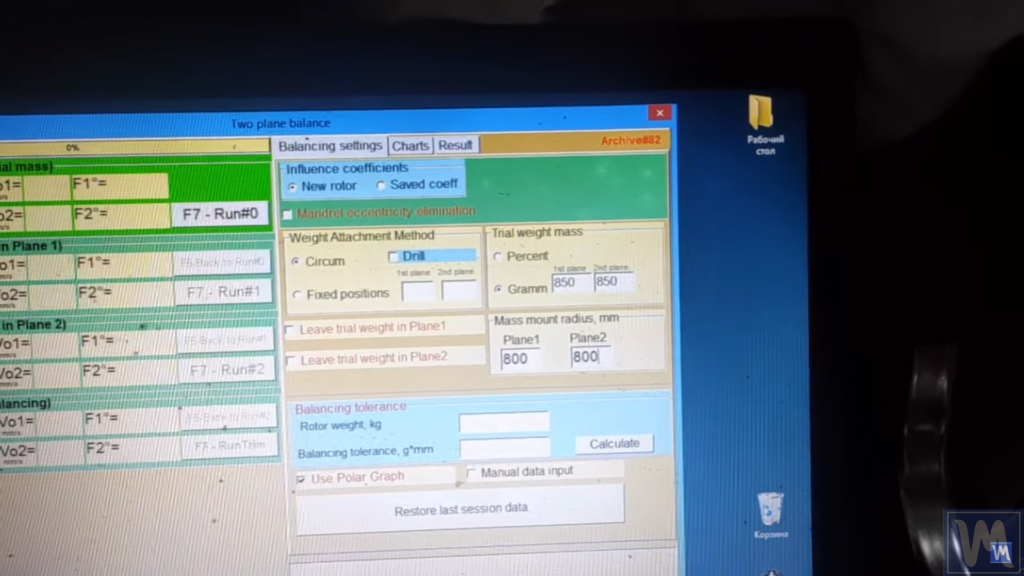

The process of balancing a centrifuge using the Balanset-1A device consists of the following steps:

- Installation of vibration sensors

- Attachment of a reflective mark

- Installation of a tachometer

- Connecting the equipment

- Launching the balancing program

- Selecting the balancing mode

- Entering data about the calibration weight

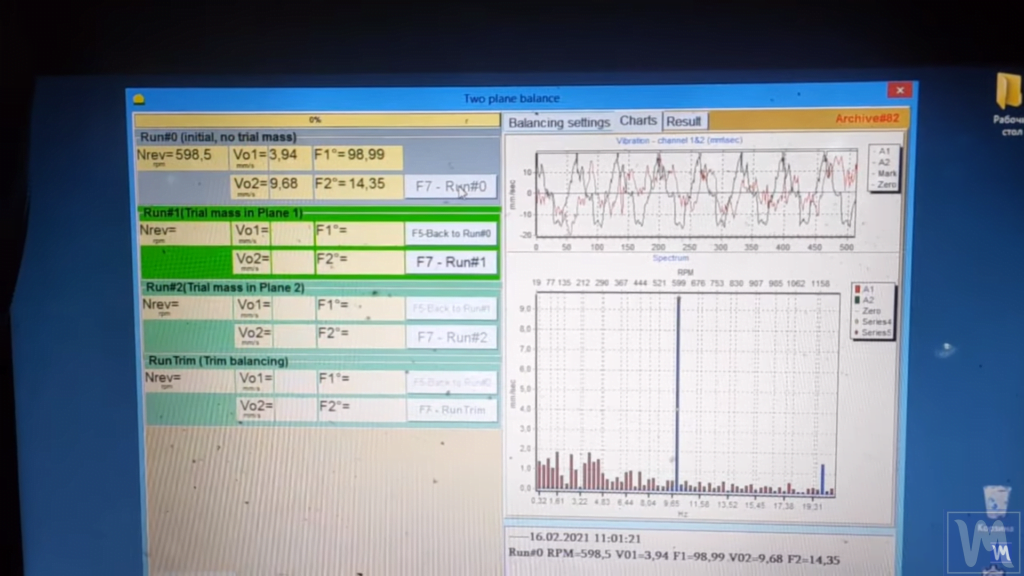

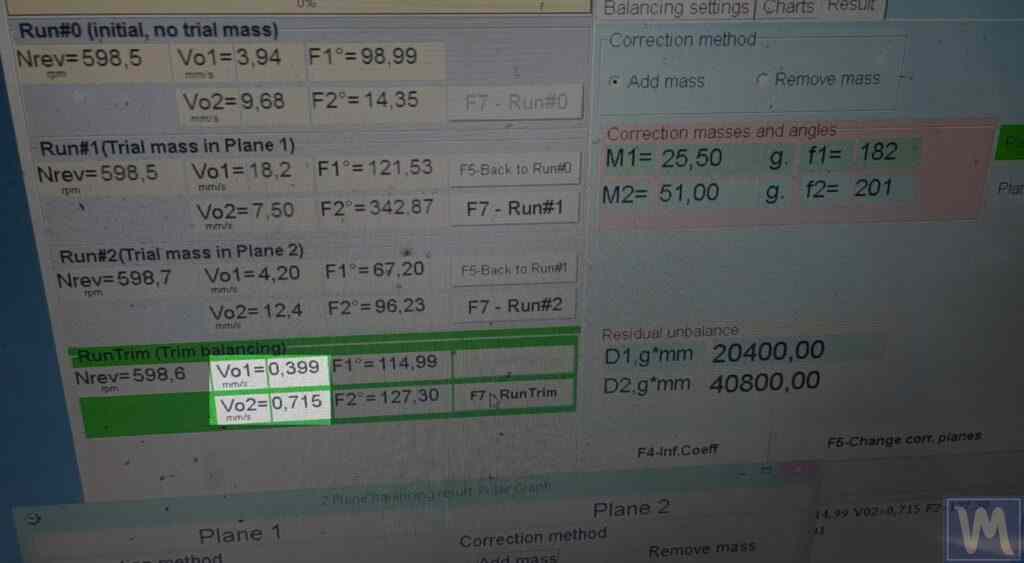

- Starting the rotor and measuring the initial level of vibration

- Placing the calibration weight in the first plane

- Re-starting the rotor and measuring vibration

- Moving the calibration weight to the second plane

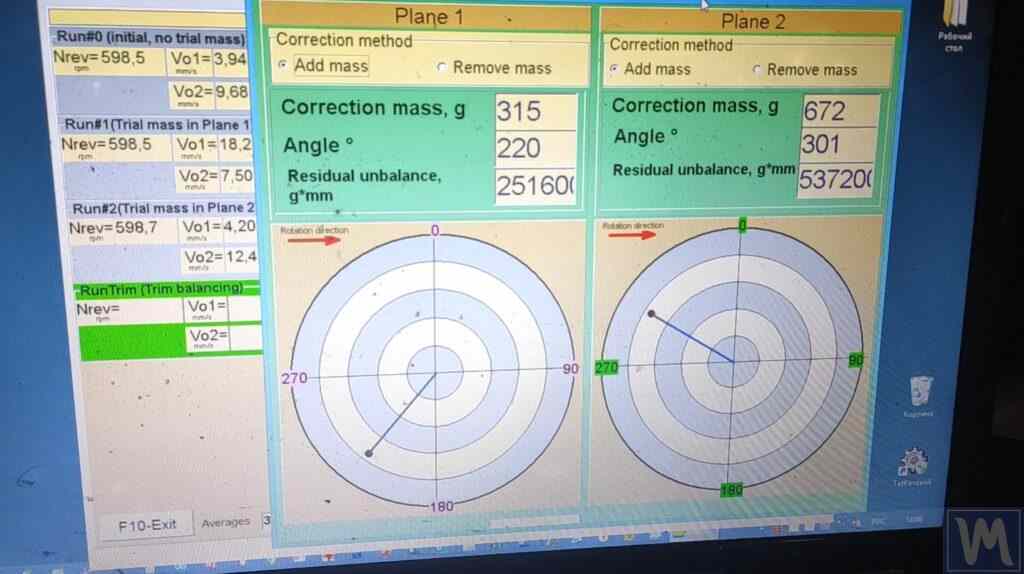

- Calculating the parameters of compensating weights

- Removing the calibration weight

- Weighing the compensating weights

- Installing compensating weights

- Control start of the rotor

Zaključak

Balancing a centrifuge is an important procedure that increases the service life of the equipment, improves its accuracy and safety of operation. The Balanset-1A is a simple and effective

tool for balancing centrifuges of various types. Its use allows for high-precision balancing in a short time.

Recommendations:

- Regularly perform centrifuge balancing, in accordance with the manufacturer’s instructions.

- Use the Balanset-1A device for centrifuge balancing.

- If necessary, involve qualified specialists in the balancing of the centrifuge.

By following these recommendations, you can:

- Ensure uninterrupted operation of the centrifuge.

- Extend the service life of the equipment.

- Increase the accuracy of component separation.

- Reduce noise and vibration levels.

- Enhance the safety of operator work.

The Balanset-1A: your reliable assistant in ensuring uninterrupted operation and longevity of your centrifuge!

0 Komentari