Vacuum pumps balancing stand

ขาตั้งปรับสมดุลโรเตอร์ความเร็วสูงสำหรับปั๊มสุญญากาศ

Introduction

การปรับสมดุลโรเตอร์ความเร็วสูงในปั๊มสุญญากาศต้องใช้เครื่องมือพิเศษที่สามารถรักษาความแม่นยำภายใต้สภาวะการทำงานที่รุนแรง เพื่อตอบสนองความต้องการเหล่านี้ จึงได้มีการพัฒนาขาตั้งปรับสมดุลเฉพาะในปี 2002 และ 2009 ระบบเหล่านี้ได้รับการออกแบบมาเพื่อปรับสมดุลแบบไดนามิกของโรเตอร์กังหันที่ประกอบแล้วที่ความเร็วการทำงานจริงตั้งแต่ 42,000 ถึง 60,000 รอบต่อนาทีโดยตรงในฐานรองรับตลับลูกปืนของตัวเอง วัตถุประสงค์ในการออกแบบคือเพื่อให้ได้ค่าความไม่สมดุลที่เหลือตามความแม่นยำระดับ 1 ตาม GOST ISO 22061-76

การออกแบบและการกำหนดค่าโครงสร้าง

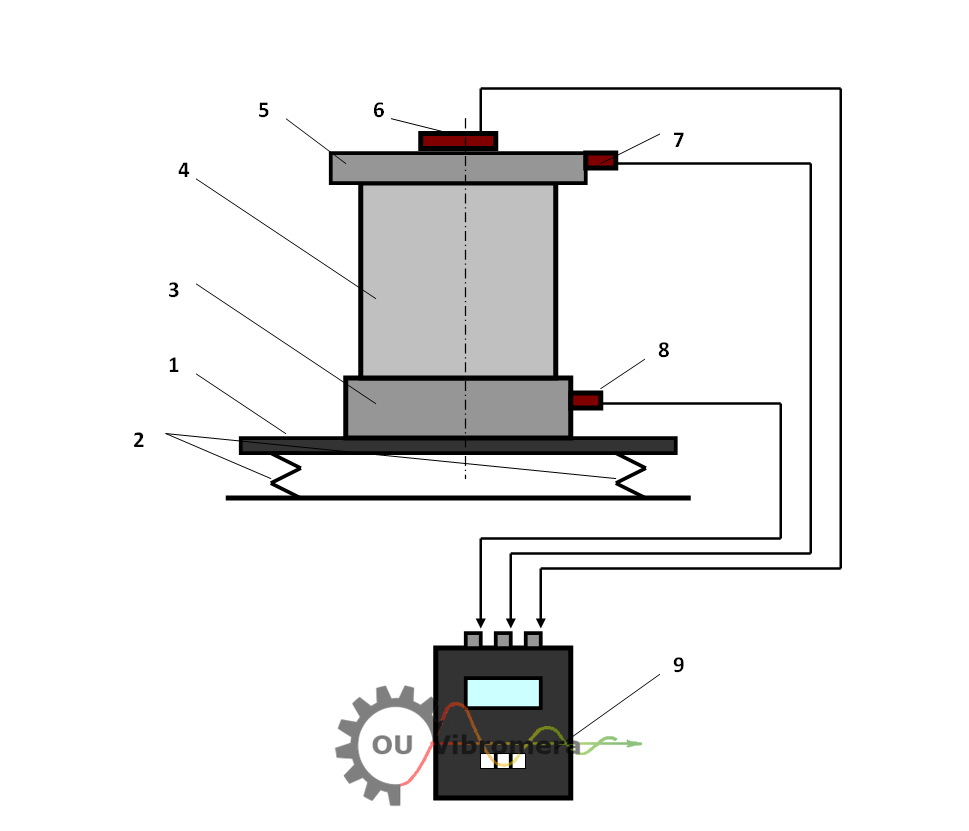

รูปที่ 1 แสดงเค้าโครงแผนผังของขาตั้งปรับสมดุลความเร็วสูงที่ใช้สำหรับโรเตอร์ปั๊มสุญญากาศ

รูปที่ 1 – การจัดวางโครงสร้างของขาตั้งปรับสมดุลปั๊มสุญญากาศความเร็วสูง:

1 – แพลตฟอร์มที่แข็งแกร่ง

2 – สปริงแยกการสั่นสะเทือนทรงกระบอก

3 – ฐานยึดรูปทรงกระบอก

4 – ปั๊มสุญญากาศสมดุล

5 – ฝาครอบป้องกัน

เซ็นเซอร์มุมเฟส 6 เฟส

7 – เซ็นเซอร์การสั่นสะเทือนบนฝาครอบ

8 – เซ็นเซอร์ตรวจจับการสั่นสะเทือนบนฐาน

9 – หน่วยการวัดและการคำนวณ

ขาตั้งสร้างขึ้นบนแพลตฟอร์มสี่เหลี่ยมผืนผ้า (1) รองรับด้วยสปริงทรงกระบอกสี่ตัว (2) ซึ่งทำหน้าที่แยกการสั่นสะเทือน แพลตฟอร์มได้รับการเสริมด้วยตัวทำให้แข็งตามยาวและตามขวาง ทำให้มีความแข็งสูงในขณะที่ลดน้ำหนักให้น้อยที่สุด โซลูชันโครงสร้างนี้ช่วยให้มีความไวสูงต่อแรงที่ไม่สมดุลและป้องกันการสั่นพ้องตลอดช่วงความเร็วทั้งหมดของปั๊มในระหว่างการปรับสมดุล

ฐานยึด (3) ติดแน่นกับแพลตฟอร์มและทำหน้าที่ในการวางตำแหน่งปั๊ม (4) อย่างแม่นยำ ปั๊มปิดด้วยฝาครอบเฉพาะ (5) ซึ่งยังบรรจุเซ็นเซอร์วัดมุมเฟส (6) ไว้ด้วย เซ็นเซอร์วัดการสั่นสะเทือนสองตัว (7 และ 8) ติดตั้งบนฝาครอบและฐานตามลำดับ เซ็นเซอร์ทั้งหมดเชื่อมต่อกับหน่วยวัดและการคำนวณ (9) ซึ่งดำเนินการวิเคราะห์แบบเรียลไทม์และคำนวณน้ำหนักแก้ไข

ขั้นตอนการปรับสมดุล

การปรับสมดุลจะดำเนินการในสองขั้นตอนต่อเนื่องเพื่อให้แน่ใจว่ามีความแม่นยำภายใต้สภาวะโรเตอร์แบบแข็งและแบบยืดหยุ่น

ขั้นตอนที่ 1 – การปรับสมดุลโรเตอร์แบบแข็ง

ในระยะเริ่มต้น โรเตอร์ของปั๊มจะถูกปรับสมดุลด้วยความเร็วรอบสูงสุดถึง 8,000 รอบต่อนาที โดยโรเตอร์จะทำหน้าที่เหมือนวัตถุแข็ง วัตถุประสงค์คือเพื่อชดเชยความไม่สมดุลทั้งแบบคงที่และแบบคู่ ระบบนี้จะทำให้ระดับการสั่นสะเทือนที่เหลือต่ำกว่า 0.01 มม./วินาที RMS ในช่วงความถี่ 3,500–8,000 รอบต่อนาที

ขั้นตอนที่ 2 – การปรับสมดุลโรเตอร์แบบยืดหยุ่นความเร็วสูง

ในขั้นตอนที่สอง การปรับสมดุลจะดำเนินการที่ความเร็วการทำงานของโรเตอร์ ซึ่งอาจเป็น 42,000 หรือ 60,000 รอบต่อนาที ขึ้นอยู่กับรุ่นของปั๊ม ที่ความเร็วนี้ โรเตอร์จะเข้าสู่สถานะยืดหยุ่นและเกิดการเสียรูป ซึ่งนำไปสู่ความไม่สมดุลแบบไดนามิกเพิ่มเติม จะมีการคำนวณการแก้ไขขั้นสุดท้ายและนำไปใช้เพื่อลดผลกระทบเหล่านี้ให้เหลือน้อยที่สุด ระดับการสั่นสะเทือนที่เหลือหลังจากการปรับสมดุลความเร็วสูงจะไม่เกิน 0.3 มม./วินาที RMS ซึ่งรับประกันการทำงานของปั๊มที่เสถียรในระยะยาว

ลักษณะการทำงาน

-

การสั่นสะเทือนตกค้าง (ระยะแข็ง) : ≤ 0.01 มม./วินาที (3,500–8,000 รอบต่อนาที)

-

การสั่นสะเทือนตกค้าง (ระยะยืดหยุ่น): ≤ 0.3 มม./วินาที (42,000–60,000 รอบต่อนาที)

-

เวลารวมของรอบในการปรับสมดุล: โดยทั่วไปใช้เวลาไม่เกิน 30 นาที

Conclusion

ขาตั้งปรับสมดุลความเร็วสูงสำหรับโรเตอร์ปั๊มสุญญากาศผสานความแข็งแกร่งของโครงสร้าง การวัดที่แม่นยำ และการคำนวณขั้นสูง ช่วยให้ปรับสมดุลได้อย่างแม่นยำภายใต้สภาวะการทำงานจริง โดยชดเชยความไม่สมดุลทั้งแบบคงที่และแบบไดนามิก โซลูชันนี้ตรงตามมาตรฐานการสั่นสะเทือนที่เข้มงวด และปรับปรุงความน่าเชื่อถือและอายุการใช้งานของระบบปั๊มสุญญากาศความเร็วสูงได้อย่างมาก