منتجات

-

موازن محمول ومحلل اهتزازات Balanset-1A

R$13,271.65 + ضريبة القيمة المضافة (إن وجدت)

موازن محمول ومحلل اهتزازات Balanset-1A

R$13,271.65 + ضريبة القيمة المضافة (إن وجدت)

-

Dynamic balancer “Balanset-1A” OEM

R$11,658.89 + ضريبة القيمة المضافة (إن وجدت)

Dynamic balancer “Balanset-1A” OEM

R$11,658.89 + ضريبة القيمة المضافة (إن وجدت)

-

Vibration sensor

R$604.78 + ضريبة القيمة المضافة (إن وجدت)

Vibration sensor

R$604.78 + ضريبة القيمة المضافة (إن وجدت)

-

Optical Sensor (Laser Tachometer)

R$833.26 + ضريبة القيمة المضافة (إن وجدت)

Optical Sensor (Laser Tachometer)

R$833.26 + ضريبة القيمة المضافة (إن وجدت)

-

Balanset-4

R$45,714.96 + ضريبة القيمة المضافة (إن وجدت)

Balanset-4

R$45,714.96 + ضريبة القيمة المضافة (إن وجدت)

موازنة المضخة الهيدروليكية باستخدام جهاز Balanset-1A

دليل عملي لمهندسي الصيانة والفنيين، يغطي تقنية الموازنة الديناميكية باستخدام جهاز Balanset-1A المحمول

1. الغرض ومبدأ التشغيل

موازنة المضخة الهيدروليكية هي إجراء لإزالة اختلال توازن الأجزاء الدوارة لتقليل الاهتزاز وزيادة عمر خدمة المعدات.

تتضمن عملية الموازنة قياس اهتزاز الدوار وطوره، ثم إضافة أو إزالة أوزان تصحيح صغيرة على المكره أو العمود. من خلال معالجة التوزيع غير المتساوي للكتلة، يُقلل هذا الإجراء بشكل كبير من قوى الطرد المركزي المسببة للاهتزاز والضرر المحتمل.

الأسباب الرئيسية لعدم التوازن:

- عدم دقة تصنيع المكره والعمود

- التآكل والتلف أثناء التشغيل

- التآكل وأضرار التجويف

- تجميع غير صحيح بعد الإصلاح

عواقب اختلال التوازن:

- زيادة الاهتزاز والضوضاء

- التآكل المتسارع للمحامل والأختام

- انخفاض كفاءة المضخة

- خطر الفشل في حالات الطوارئ

2. الوصف الفني لجهاز Balanset-1A

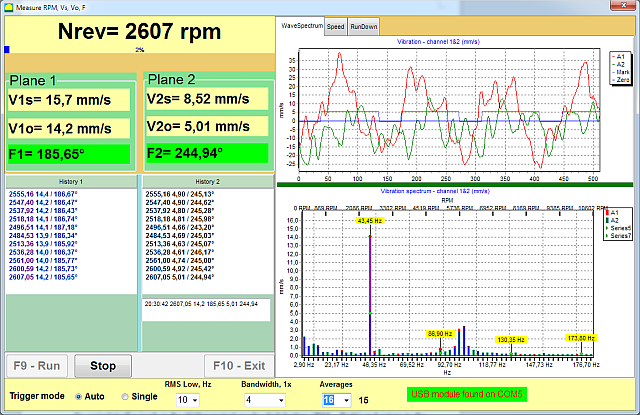

Balanset-1A هو جهاز محمول ثنائي القناة لتحقيق التوازن الديناميكي للدوارات مباشرة في مكان العمل (في الموقع).

هيكل نظام Balanset-1A

المواصفات الفنية

| المعلمة | قيمة | وحدة |

|---|---|---|

| نطاق قياس سرعة الاهتزاز (RMS) | 0.02 - 80 | مم/ثانية |

| نطاق التردد | 5 - 550 | هرتز |

| نطاق قياس سرعة الدوران | 100 - 100,000 | دورة في الدقيقة |

| دقة قياس الطور | ±1 | درجة |

| عدد طائرات التصحيح | 1 or 2 | - |

| درجة حرارة التشغيل | +5...+50 | درجة مئوية |

محتويات حزمة الجهاز

واجهة USB مع مكبرات صوت مسبقة ومحول تناظري رقمي

2 مقياس تسارع مع حامل مغناطيسي

مستشعر الطور مع حامل مغناطيسي

للتثبيت على عمود المضخة

لقياس الوزن بدقة

على محرك أقراص USB مع التعليمات

3. التحضير للموازنة

تركيب المستشعر

مخطط تركيب المستشعر على المضخة الهيدروليكية

- قم بتركيب أجهزة استشعار الاهتزاز على غلاف المضخة بالقرب من المحامل، بحيث تكون موجهة بشكل عمودي على محور العمود

- قم بتثبيت شريط عاكس على عمود المضخة أو الوصلة

- قم بتركيب مقياس سرعة الدوران بالليزر على حامل مغناطيسي مقابل الشريط العاكس

- ربط المستشعرات بوحدة القياس

- قم بتوصيل وحدة القياس بالكمبيوتر المحمول عبر USB

4. إجراء الموازنة

عادةً ما تتبع عملية الموازنة باستخدام Balanset-1A طريقة ثلاثية التشغيل (طريقة معامل التأثير) باستخدام أوزان تجريبية. فيما يلي شرح تفصيلي للعملية، بدءًا من قياس الاهتزاز الأولي ووصولًا إلى تركيب أوزان التصحيح والتحقق من النتائج.

قياس الاهتزاز الأولي

- بدء تشغيل برنامج Balanset-1A

- حدد وضع الموازنة أحادي المستوى أو ثنائي المستوى

- قم بتشغيل المضخة بسرعة التشغيل

- اضغط على "Run#0" في البرنامج لقياس الاهتزاز الأولي

- سجل سعة الاهتزاز وقيم الطور

تركيب الوزن التجريبي

- أوقف المضخة

- وزن وزن تجريبي مناسب باستخدام الميزان الإلكتروني

- قم بتثبيت الوزن على الدوار في المستوى التصحيحي الأول

- أدخل كتلة الوزن ونصف قطر التثبيت في البرنامج

- أعد تشغيل المضخة وقم بإجراء القياس "Run#1"

قياس المستوى الثاني (لموازنة المستويين)

- أوقف المضخة وأزل الوزن التجريبي من المستوى الأول

- قم بربط وزن الاختبار بمستوى التصحيح الثاني

- قم بتشغيل المضخة وقم بإجراء القياس "Run#2"

- سيقوم البرنامج بحساب أوزان التصحيح المطلوبة تلقائيًا

تركيب وزن التصحيح

- أوقف المضخة وأزل أي أوزان تجريبية

- تصنيع أو تحديد أوزان التصحيح حسب حسابات البرنامج

- تأمين الأوزان عن طريق اللحام أو البراغي أو استخدام المشابك

- يتم قياس زاوية التثبيت لكل وزن من موضع الوزن التجريبي في اتجاه الدوران

قياس التحقق

- قم بتشغيل المضخة بسرعة التشغيل

- إجراء قياس التحكم ("RunTrim")

- تأكد من أن الاهتزاز قد تم تقليله إلى مستويات مقبولة

- ضبط كتل الوزن وتكرار القياس إذا لزم الأمر

5. موازنة معايير تقييم الجودة

قيم الاهتزاز المتبقية المقبولة

| نوع المضخة | الاهتزاز المقبول، مم/ثانية | Note |

|---|---|---|

| مضخات الطرد المركزي حتى 15 كيلو وات | ≤ 2.8 | حالة جيدة |

| مضخات الطرد المركزي 15-75 كيلو واط | ≤ 4.5 | حالة جيدة |

| مضخات الطرد المركزي التي تزيد عن 75 كيلو وات | ≤ 7.1 | حالة جيدة |

| أي مضخات | > 11.2 | غير مقبول |

علامات التوازن الناجح

- 70–90% انخفاض في الاهتزاز عند التردد الدوراني 1×

- قراءات مرحلة الاهتزاز مستقرة ومتسقة

- عدم وجود ضوضاء غير عادية

- تشغيل المضخة بشكل سلس وموحد

6. التوصيات العملية

موازنة التردد

الموازنة المجدولة

- المعدات الجديدة – بعد فترة التشغيل الأولية

- بعد الإصلاحات الكبرى – إلزامي

- سنويا للمعدات الحيوية

- عندما تتضاعف مستويات الاهتزاز عن خط الأساس

الموازنة غير المجدولة

- عند ملاحظة اهتزاز أو ضوضاء غير عادية

- بعد أي استبدال للمكره

- إذا تجاوز الاهتزاز المستويات المقبولة

- بعد الإغلاق الطارئ

متطلبات موازنة الجودة

- تأكد من أن المضخة في حالة ميكانيكية جيدة

- تأكد من تثبيت المضخة بشكل ثابت على أساس مستقر

- تأكد من عدم وجود حركة زائدة في المحامل

- تأكد من المحاذاة الصحيحة بين المضخة والسائق

- الحفاظ على سرعة التشغيل الثابتة أثناء الموازنة

توثيق النتائج

- احتفظ بسجل لجميع أعمال الموازنة التي تم إجراؤها

- احفظ تقارير برنامج Balanset-1A لكل مهمة موازنة

- توثيق كتلة وموضع أوزان التصحيح المثبتة

- سجل مستويات الاهتزاز النهائية بعد الموازنة (قياسات التحكم)

Conclusion

يوفر جهاز Balanset-1A المحمول موازنة فعّالة للمضخات الهيدروليكية مباشرةً في مكان العمل. يتيح الاستخدام الأمثل لهذه التقنية للمستخدمين ما يلي:

- تقليل اهتزاز المعدات بعامل يتراوح بين 3 إلى 10

- زيادة عمر خدمة المحمل بمقدار 2-5 مرات

- انخفاض استهلاك الطاقة بمقدار 5–15%

- منع الأعطال الطارئة

- تقليل تكاليف الصيانة الإجمالية

يعد التوازن المنتظم للمضخات الهيدروليكية جزءًا مهمًا من نظام الصيانة الوقائية المخطط للمعدات الصناعية.

الأسئلة الشائعة

ما هو موازنة المضخة الهيدروليكية؟

موازنة المضخة الهيدروليكية هي عملية تصحيح التوزيع غير المتساوي للكتلة في مكوناتها الدوارة (مثل المكره والعمود). ويهدف إضافة أو إزالة أوزان صغيرة إلى التخلص من الاهتزازات والضوضاء الزائدة، مما يُحسّن الأداء ويُطيل عمر المضخة.

لماذا يعد موازنة المضخة الهيدروليكية أمرا مهما؟

يُعدّ موازنة المضخة أمرًا بالغ الأهمية، إذ يُمكن أن تُسبب اهتزازات وضوضاء مفرطة، مما يُؤدي إلى تآكل مُتسارع للمحامل والأختام، وانخفاض الكفاءة، وزيادة خطر الأعطال المفاجئة. تُساعد الموازنة السليمة على ضمان تشغيل المضخة بسلاسة وكفاءة وموثوقية.

كيف تقوم بموازنة المضخة الهيدروليكية؟

تُجرى موازنة المضخة الهيدروليكية عادةً باستخدام جهاز مثل Balanset-1A. تتضمن العملية قياس اهتزاز المضخة وطورها، وإضافة وزن تجريبي إلى الدوار، وقياس التغير، ثم حساب وتركيب وزن تصحيح في موقع محدد. بعد تركيب وزن التصحيح، تُشغّل المضخة مرة أخرى للتحقق من انخفاض مستويات الاهتزاز إلى الحدود المقبولة.

ما هي المعدات المستخدمة في موازنة المضخة؟

تتطلب موازنة المضخة نظامًا لقياس الاهتزازات وموازنة المضخة. على سبيل المثال، تتضمن مجموعة Balanset-1A وحدة واجهة USB، ومستشعري اهتزاز (مقياسي تسارع)، ومقياس سرعة دوران ليزر (مستشعر مرجع الطور)، وشريطًا عاكسًا للدوار، ومقاييس إلكترونية لوزن أوزان الاختبار والتصحيح، وبرنامجًا متخصصًا يعمل على جهاز كمبيوتر محمول لتوجيه عملية الموازنة.

كم مرة يجب أن تتم موازنة المضخة؟

يجب موازنة المضخات عند حدوث اهتزازات كبيرة أو بعد أي أحداث قد تُسبب اختلالًا في التوازن. يُنصح بموازنة المضخات الجديدة بعد فترة التشغيل الأولية، وبعد الإصلاحات الرئيسية أو استبدال المكره، وكجزء من الصيانة السنوية للمضخات الحرجة. يُنصح بإجراء موازنة غير مُجدولة في حال ظهور اهتزازات أو ضوضاء غير عادية، أو بعد أي توقف طارئ.

ما هي مستويات الاهتزاز المقبولة للمضخة المتوازنة؟

تعتمد مستويات الاهتزاز المقبولة على حجم المضخة وقوتها. على سبيل المثال، عادةً ما يكون معدل اهتزاز مضخات الطرد المركزي الصغيرة (حتى 15 كيلوواط) ≤ 2.8 مم/ثانية (RMS) عند توازنها الجيد. أما المضخات المتوسطة (15-75 كيلوواط) فيجب أن يكون ≤ 4.5 مم/ثانية، والمضخات الكبيرة (>75 كيلوواط) ≤ 7.1 مم/ثانية. أي مضخة يتجاوز معدل اهتزازها 11.2 مم/ثانية تقريبًا تُعتبر اختلالًا غير مقبول وتحتاج إلى عناية.

هل يؤدي التوازن إلى إصلاح جميع مشاكل الاهتزاز؟

لا. تُعالج عملية الموازنة الاهتزازات الناتجة عن اختلال توازن كتلة الدوار. تُقلل هذه العملية الاهتزازات بشكل ملحوظ عند تردد الدوران، لكنها لا تُعالج مصادر الاهتزاز الأخرى، مثل عدم المحاذاة، أو تآكل المحامل، أو انحناء الأعمدة، أو أي مشاكل ميكانيكية أخرى. يجب تشخيص هذه المشاكل وإصلاحها بشكل منفصل.