Vibration Analysis and Reduction Methods for Industrial Equipment

Published by Nikolai Shelkovenko on

Complete Guide to Understanding and Reducing Vibration in Industrial Equipment

Fundamental knowledge for ensuring reliability, efficiency, and safety of industrial operations

1.1 Introduction: Why Equipment Vibration Cannot Be Ignored

In the world of industrial production, vibration is an inevitable companion of operating equipment. However, there exists a critical boundary between normal operational vibration and problematic vibration that is important to understand and control. Machine and mechanism vibration represents a complex physical phenomenon that can serve both as an indicator of normal functioning and as a harbinger of serious technical problems.

Critical Importance of Vibration Monitoring

Statistical data from industrial enterprises shows that up to 85% of all rotating equipment failures are accompanied by changes in vibration characteristics long before actual breakdown. This means that proper vibration monitoring can prevent the overwhelming majority of unplanned production shutdowns.

Vibration is often the first audible or tangible sign that something is wrong with equipment. The human ear is capable of distinguishing changes in the acoustic characteristics of operating machines, which historically served as the primary diagnostic method for experienced mechanics and operators. However, modern requirements for diagnostic accuracy and reliability far exceed the capabilities of human senses.

While a certain level of vibration is inherent to the operation of many devices and is a natural consequence of dynamic processes in mechanisms, excessive vibration is a clear symptom of underlying problems that can lead to serious consequences. It is important to understand that the boundary between normal and problematic vibration is not an absolute value, but depends on many factors, including equipment type, operating conditions, machine age, and accuracy requirements for performed operations.

Principle of Preventive Balancing

As correctly stated in technical literature: "Balancing is prevention." This principle emphasizes the fundamental truth of industrial maintenance: preventing problems is always more effective and economical than subsequent elimination.

If a part is not properly balanced, forces that cause vibrations, noise, and accelerated component wear will inevitably arise. This process develops according to exponential law: a small initial imbalance over time leads to increased clearances in bearings, which in turn exacerbates vibration and accelerates further wear. Thus, a vicious cycle of equipment degradation is formed.

Understanding and managing vibration, therefore, is a fundamental foundation for ensuring the reliability, efficiency, and safety of industrial operations. Modern production processes are characterized by a high degree of automation and integration, which means that failure of one element can paralyze the entire technological chain. Under such conditions, the cost of ignoring vibration problems can be catastrophic.

It is necessary to distinguish between normal operational vibration and that which is problematic and symptomatic. Normal vibration is characterized by stable parameters over time, predictable frequency characteristics related to equipment operating frequencies, and amplitudes not exceeding established standards. Problematic vibration, on the contrary, manifests through parameter instability, appearance of new frequency components, sharp amplitude increases, or changes in phase relationships.

Linking problematic vibration to negative results such as wear, failures, and costs creates a sense of urgency and relevance for technical personnel. Statistics show that unplanned production shutdowns cost on average 50-100 times more than planned maintenance. Moreover, most such shutdowns can be prevented through timely vibration diagnostics.

Modern technologies allow not only detecting problems at an early stage but also predicting defect development, planning optimal intervention time, and minimizing impact on the production process. This is especially important in conditions of fierce competition, where every hour of downtime can mean loss of market position.

Economic Justification for Vibration Monitoring

Research shows that every dollar invested in a vibration monitoring system brings from 5 to 20 dollars in savings through prevention of emergency situations, optimization of repair planning, and increase in maintenance intervals.

It is also important to consider the human factor in safety matters. Excessive vibration can create discomfort for operators, reduce their productivity and attention, which in turn increases the risk of accidents. Additionally, prolonged exposure to vibration on humans can lead to occupational diseases, creating additional legal and financial risks for the enterprise.

In the context of modern requirements for enterprise environmental responsibility, vibration control also plays an important role in reducing environmental impact. Optimally operating equipment consumes less energy, produces less noise and emissions, which corresponds to sustainable development principles and can be an important factor when obtaining environmental certificates and permits.

1.2 The Science of Mechanical Vibration: Key Concepts

Mechanical vibration represents a complex physical phenomenon that can be defined as oscillation of a mechanical body or system around an equilibrium position. This definition, although it seems simple, conceals many nuances and complexities, understanding of which is critically important for effective diagnostics and vibration management in industrial equipment.

where: x(t) - displacement in time, A - amplitude, ω - angular frequency, φ - phase

Several fundamental parameters are used to describe and quantitatively assess vibration, each of which carries important diagnostic information. Understanding these parameters and their interrelationships is the basis for competent analysis of equipment condition.

Vibration Amplitude: Indicator of Problem Severity

Amplitude indicates the magnitude of vibration, that is, how much a component moves relative to its equilibrium position. This parameter can be measured in different units, each of which is suitable for certain types of analysis and diagnostics.

Displacement (usually measured in millimeters or micrometers) shows the maximum deviation from equilibrium position. This parameter is especially important for low-frequency vibrations and when analyzing foundation oscillations. Large displacement values may indicate problems with system stiffness or resonance phenomena.

Vibration velocity (measured in mm/s or inch/s) is the most universal parameter for diagnosing most mechanical problems in the frequency range from 10 Hz to 1000 Hz. International standards such as ISO 20816 are based precisely on vibration velocity measurements. This parameter correlates well with vibration energy and, consequently, with potential equipment damage.

| Parameter | Units | Application | Frequency Range |

|---|---|---|---|

| Displacement | mm, μm | Low-frequency oscillations, imbalance | 2-200 Hz |

| Velocity | mm/s | General diagnostics, ISO standards | 10-1000 Hz |

| Acceleration | m/s², g | High-frequency defects, bearings | 1000-20000+ Hz |

Vibration acceleration (measured in m/s² or in g units, where g = 9.81 m/s²) is most sensitive to high-frequency vibration components and is used for diagnosing bearing defects, gear transmissions, and other high-frequency vibration sources. Acceleration is proportional to the force acting on the structure, making it important for assessing structural loads.

Large amplitude usually indicates a more serious problem, however, it is important to understand that absolute amplitude values must be interpreted in the context of equipment type, operating conditions, and measuring system characteristics. For example, a vibration amplitude of 5 mm/s may be normal for a large low-speed motor, but critical for a high-speed CNC machine spindle.

Vibration Frequency: Key to Source Identification

Frequency refers to the rate of vibration occurrence and is usually expressed in Hertz (Hz), corresponding to the number of cycles per second, or in cycles per minute (CPM), which is especially convenient when analyzing rotating equipment since it directly relates to revolutions per minute (RPM).

10 Hz - 10 kHz

Frequency analysis is one of the most powerful diagnostic tools because different types of defects manifest at characteristic frequencies. For example, rotor imbalance manifests at rotation frequency (1X RPM), shaft misalignment creates vibration at double rotation frequency (2X RPM), and bearing defects generate vibration at specific frequencies depending on bearing geometry and rotation speed.

The mathematical relationship between revolutions per minute and frequency in Hertz is expressed by a simple formula: f(Hz) = RPM/60. This relationship allows easy conversion of rotation speed to fundamental harmonic frequency and analysis of multiple frequencies (harmonics), which often contain important diagnostic information.

Harmonic Analysis in Diagnostics

The appearance of significant harmonics (2X, 3X, 4X of rotation frequency) often indicates nonlinear processes in equipment, such as backlash, impacts, or aerodynamic pulsations. Analysis of harmonic composition allows diagnosing problems that may not be obvious when analyzing only the fundamental frequency.

Vibration Phase: Spatial Information about Movement

Phase describes vibrational movement of one part of a machine relative to another or to a fixed reference point. This parameter is especially important when diagnosing certain types of imbalance, misalignment, and other defects that manifest in characteristic phase relationships between different measurement points.

Phase analysis requires simultaneous vibration measurement at several points using a reference signal, usually from a tachometer or strobe. Phase difference between different measurement points can indicate the type and location of the problem. For example, imbalance is usually characterized by in-phase movement of bearing supports, while misalignment manifests as out-of-phase movement.

In-phase Movement

Characteristic of mass imbalance, when all points move in the same direction simultaneously

Out-of-phase Movement

Typical for shaft misalignment, when points move in opposite directions

Quadrature Movement

May indicate elliptical rotor movement or combination of defects

Importance of Frequency Characteristics in Diagnostics

It is important to note that different mechanical problems tend to manifest with distinctive vibrational characteristics, especially at certain frequencies. This pattern is the basis for developing expert diagnostic systems and automatic defect recognition algorithms.

Sub-harmonics (frequencies below the fundamental rotation frequency, such as 0.5X, 0.33X) may indicate rotation instability, rolling bearing problems, or oil wedge issues in sliding bearings. The appearance of sub-harmonics is often a sign of developing serious problems.

Understanding these basic concepts is necessary, especially for readers who are not vibration specialists but must understand the nature of the problem to make informed decisions about maintenance and repair. This knowledge lays the foundation for subsequent discussions of more complex analysis methods such as spectral analysis, envelope analysis, and cepstral analysis.

Stage 1: Basic Parameter Measurement

Determining amplitude, frequency, and phase of vibration at key equipment points

Stage 2: Spectral Analysis

Decomposing complex signal into frequency components to reveal characteristic defect signatures

Stage 3: Trend Analysis

Tracking parameter changes over time to predict defect development

Stage 4: Integrated Diagnostics

Comprehensive analysis of all available data for accurate determination of problem type and severity

Modern vibration analysis systems are capable of processing huge volumes of data in real time, detecting even weak signs of developing defects. Machine learning and artificial intelligence are increasingly applied for automatic pattern recognition in vibration signals, significantly improving diagnostic accuracy and speed.

1.3 Common Culprits: Identifying Root Causes of Excessive Vibration

Excessive vibration in industrial equipment is rarely an isolated problem. As a rule, it is a symptom of one or several defective conditions that can develop independently or in interaction with each other. Understanding these root causes is critically important for effective diagnostics and prevention of serious equipment failures.

Imbalance: The Most Common Cause of Vibration

Imbalance occurs due to uneven mass distribution in rotating components, creating a "heavy spot" that causes centrifugal forces and, consequently, vibration. This is one of the most common causes of vibration in motors, rotors, fans, pumps, and other rotating equipment.

Static Imbalance

Center of gravity does not coincide with rotation axis. Manifests in one plane and causes radial vibration at rotation frequency.

Dynamic Imbalance

Inertia axis does not coincide with rotation axis. Requires correction in two planes and creates moments causing rotor rocking.

Mathematically, centrifugal force from imbalance is expressed by the formula:

where: m - unbalanced mass, r - imbalance radius, ω - angular velocity

From this formula, it is evident that imbalance force is proportional to the square of rotation speed, which explains why imbalance problems become especially critical at high speeds. Doubling rotation speed leads to a four-fold increase in imbalance force.

Causes of imbalance are diverse and include manufacturing errors, uneven wear, accumulation of contamination, loss of balancing weights, deformations from temperature effects, and corrosion. During operation, imbalance can gradually increase, requiring periodic equipment rebalancing.

Progressive Nature of Imbalance

Imbalance tends to be self-reinforcing: initial imbalance causes increased loads on bearings, leading to their accelerated wear and increased clearances, which in turn exacerbates imbalance and creates a vicious cycle of degradation.

Misalignment: Hidden Threat to Reliability

Misalignment occurs when the axes of connected machines (e.g., motor and pump) are incorrectly aligned. There are two main types of misalignment: parallel (axis offset) and angular (axis intersection at an angle). In practice, combined misalignment is most common, including both types.

Misalignment creates cyclic loads on couplings, bearings, and shafts, which manifest as vibration, predominantly at double rotation frequency (2X RPM). However, other harmonics may also be present, depending on the type and degree of misalignment, as well as coupling characteristics.

| Misalignment Type | Main Frequencies | Vibration Direction | Characteristic Signs |

|---|---|---|---|

| Parallel | 2X RPM | Radial | High vibration in radial direction |

| Angular | 1X, 2X RPM | Axial | Significant axial vibration |

| Combined | 1X, 2X, 3X RPM | Radial + axial | Complex spectrum with multiple harmonics |

Acceptable misalignment limits depend on rotation speed and equipment type. For precision high-speed equipment, acceptable deviations may be only a few hundredths of a millimeter, while for low-speed machines tolerances may be more generous. However, in any case, precise alignment is critically important for reliable operation and long equipment service life.

Mechanical Looseness: Source of Instability

Mechanical looseness implies excessive clearance between components and can manifest in various forms: loose foundation or mounting bolts, worn bearings with too much internal clearance, poor fit of parts on shaft, wear of key connections, deformation of housing parts.

Looseness can amplify other vibration sources, acting as an amplifier for imbalance or misalignment forces. Additionally, looseness can create nonlinear effects such as impacts and knocks, which generate broadband vibration and high-frequency components.

Diagnostic Signs of Looseness

Looseness often manifests through instability of vibration readings, appearance of sub-harmonics, and complex spectrum with multiple peaks. A characteristic sign is also dependence of vibration level on equipment load.

Bearing Defects: High-Frequency Problem Indicators

Wear, pitting, or damage to raceways or rolling elements of bearings is a major cause of high-frequency vibration. Bearings generate characteristic frequencies related to their geometry and kinematics:

BPFI = (n/2) × (1 + d/D × cos α) × RPM/60

BSF = (D/2d) × (1 - (d/D × cos α)²) × RPM/60

FTF = (1/2) × (1 - d/D × cos α) × RPM/60

where: n - number of rolling elements, d - rolling element diameter, D - pitch diameter, α - contact angle

These formulas allow calculation of characteristic bearing defect frequencies: BPFO (Ball Pass Frequency Outer race), BPFI (Ball Pass Frequency Inner race), BSF (Ball Spin Frequency), and FTF (Fundamental Train Frequency).

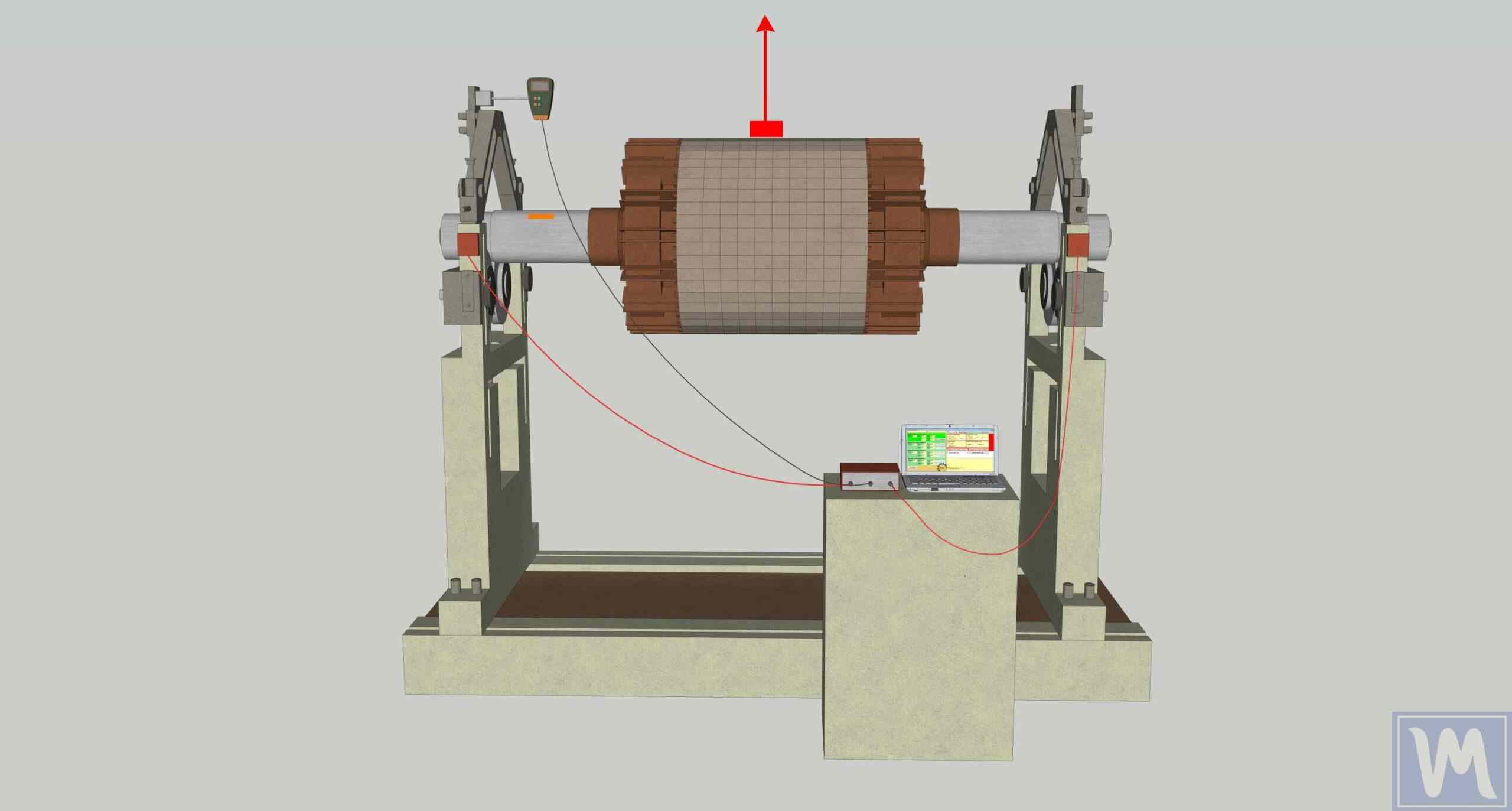

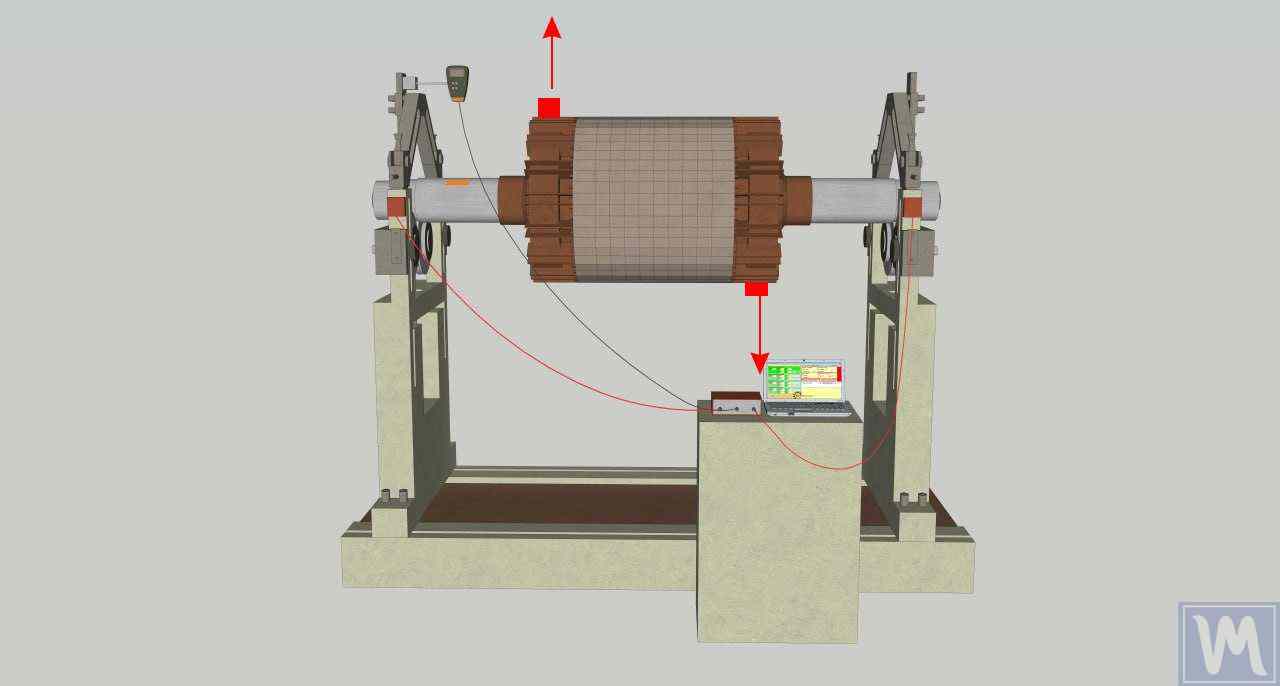

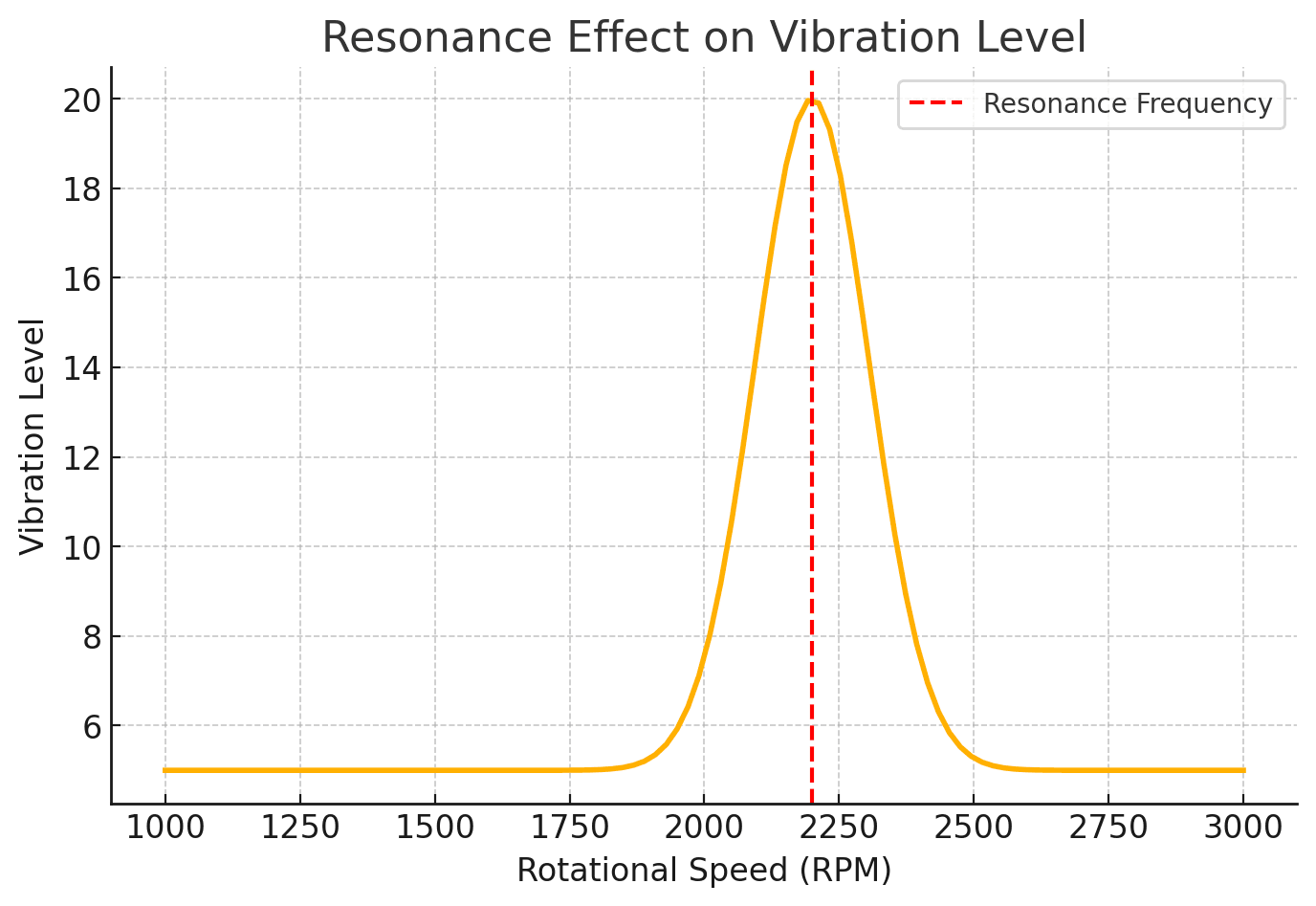

Resonance: Amplifier of All Problems

Resonance occurs when excitation frequency (e.g., rotation speed or its multiples) coincides with the natural frequency of the machine or its structure. This leads to sharp vibration amplification, which can be catastrophic in its consequences.

Resonance Phenomenon

Resonance amplifies vibration when excitation frequency matches natural frequency

Resonance phenomena are especially dangerous during equipment startup and shutdown when rotation frequency passes through critical values. Modern control systems often include algorithms for rapid passage through resonance zones to minimize amplified vibration exposure time.

Additional Causes of Vibration

Besides main causes, there are many other factors that can cause excessive vibration:

Bent shafts create vibration at rotation frequency and its harmonics, with vibration character depending on degree and type of bend. Thermal bends can occur due to uneven heating or cooling of shafts.

Gear transmission problems include tooth wear, broken or chipped teeth, manufacturing inaccuracies, incorrect clearances. Gear transmissions generate vibration at mesh frequency (number of teeth × RPM) and its harmonics.

Electrical problems in motors may include uneven air gaps, broken rotor bars, commutation problems in DC motors, phase imbalance in three-phase motors. These problems often manifest at frequencies related to mains frequency.

Comprehensive Approach to Diagnostics

It is important to understand that in real operating conditions, several vibration sources are often present simultaneously. Effective diagnostics requires comprehensive analysis of all possible causes and their interaction.

Modern diagnostic systems use defect signature databases and expert systems for automatic recognition of various problem combinations. This allows not only detecting the presence of a defect but also assessing its severity, development speed, and elimination priority.

1.4 The Domino Effect: Consequences of Uncontrolled Vibration on Efficiency, Service Life, and Safety

Ignoring excessive vibration triggers a cascading degradation process that can be compared to the domino effect - one falling tile inevitably leads to the fall of all others. In the context of industrial equipment, this means that a small initial problem, left unattended, can lead to catastrophic consequences for the entire production system.

Accelerated Component Wear: First Link in the Chain of Destruction

Accelerated component wear is one of the most direct and most obvious consequences of excessive vibration. This process affects virtually all machine elements, but the most vulnerable are bearings, seals, shafts, couplings, and even machine foundations.

Bearings are especially sensitive to vibration because it creates additional dynamic loads that accelerate fatigue failure of metal. Research shows that increasing vibration level by only 20% can reduce bearing service life by 40-50%. This occurs because fatigue durability of bearings is inversely proportional to the cube of applied load according to the Lundberg-Palmgren equation.

Seals also suffer from vibration because it disrupts stability of contact between sealing surfaces. This leads to lubricant leakage, contamination ingress, and further deterioration of bearing operating conditions. Statistics show that seal service life can be reduced by 3-5 times in the presence of significant vibration.

Shafts are subjected to cyclic stresses from vibration, which can lead to fatigue cracks, especially in stress concentration zones such as bearing seat areas, keyways, or diameter transitions. Development of fatigue cracks in shafts is especially dangerous because it can lead to sudden catastrophic failure.

Progressive Nature of Wear

Component wear from vibration has a progressive character: as clearances in bearings increase, vibration amplitude increases, which further accelerates wear. This process can develop exponentially, especially after exceeding a certain threshold level.

Loss of Operational Efficiency: Hidden Energy Losses

Vibration inevitably leads to loss of operational efficiency because energy is dissipated as mechanical oscillations instead of performing useful work. This leads to increased energy consumption, which can be from 5% to 25% depending on problem severity and equipment type.

Additional energy consumption arises from several sources:

- Friction losses: Increased vibration raises friction in bearings and other contacting surfaces

- Aerodynamic losses: Fan blade and rotor oscillations reduce their efficiency

- Drive losses: Misalignment and other defects increase losses in couplings and gearboxes

- Deformation losses: Energy is spent on elastic deformations of structures

In production processes requiring high precision, vibration can jeopardize final product quality. This is especially critical in industries such as semiconductor manufacturing, precision machining, pharmaceutical industry, where even minimal vibrations can lead to product defects.

Economic Consequences: Hidden and Obvious Costs

Maintenance costs increase due to more frequent repairs and, critically, due to unplanned downtime. Statistical data from industrial enterprises shows the following cost structure related to vibration problems:

| Cost Type | Share of Total Losses | Average Cost | Prevention Possibility |

|---|---|---|---|

| Unplanned downtime | 60-70% | $50,000-500,000/hour | 90-95% |

| Emergency repair | 15-20% | 3-5x planned cost | 80-90% |

| Product quality losses | 10-15% | Industry dependent | 95-99% |

| Increased energy consumption | 5-10% | 5-25% of energy budget | 85-95% |

Especially painful are unplanned downtime, the cost of which can reach hundreds of thousands of dollars per hour for large production lines. For example, in the petrochemical industry, stopping a cracking unit can cost $500,000-1,000,000 per day, not counting losses from breach of contractual obligations.

Safety Risks: Threat to Personnel and Environment

There are serious occupational safety risks because uncontrolled vibration can lead to structural or catastrophic equipment failures with potential for personnel harm. Industrial history knows many cases where ignoring vibration problems led to tragic consequences.

Examples of Catastrophic Failures

The turbogenerator failure at Sayano-Shushenskaya HPP in 2009 was partially related to vibration problems. The accident resulted in 75 deaths and billions of rubles in damage. Such cases emphasize the critical importance of vibration monitoring for safety.

Main safety risks include:

- Mechanical injuries: From flying parts of destroyed equipment

- Fires and explosions: From leaks of combustible liquids or gases due to seal failure

- Chemical poisoning: When systems with toxic substances are depressurized

- Structural collapses: When foundations or supporting structures fail

Excessive noise created by vibrations also causes serious concerns. It affects operator comfort, reduces concentration, and can lead to occupational hearing diseases. Prolonged exposure to noise above 85 dB can cause irreversible hearing loss, creating legal risks for employers.

Environmental Consequences: Hidden Impact on Environment

Energy inefficiency caused by vibration contributes to negative environmental impact through increased CO₂ and other greenhouse gas emissions. With annual energy consumption of large industrial enterprises in hundreds of gigawatt-hours, even 5% inefficiency can mean additional thousands of tons of CO₂ emissions.

Additionally, vibration problems can lead to:

- Leaks of process fluids into the environment

- Increased waste generation from accelerated wear

- Noise pollution of surrounding territory

- Disruption of technological process stability with environmental consequences

Cost of Inaction

Analysis of real cases shows that the cost of ignoring vibration problems can exceed the cost of their elimination by 10-100 times. Moreover, most problems can be prevented through regular monitoring and timely intervention.

Comprehensive Impact on Business Processes

Detailed description of all these negative consequences reinforces the need for proactive vibration management and creates a clear understanding of the "need" that modern diagnostic solutions are designed to satisfy. It is important to understand that consequences of vibration problems extend far beyond technical aspects and affect all business levels:

- Operational level: Reduced productivity, increased maintenance costs

- Tactical level: Disruption of production plans, supply problems

- Strategic level: Loss of competitive advantages, reputation damage

Modern economic realities require enterprises to achieve maximum efficiency and minimize risks. In this context, proactive vibration management becomes not just a technical necessity but a strategic advantage that can determine success or failure in competitive struggle.

1.5 Diagnostic Pathways: Overview of Vibration Analysis Tools and Methods

The vibration diagnostic process represents a comprehensive methodology that combines advanced measurement technologies, complex analysis algorithms, and expert knowledge to transform "raw" vibration data into valuable diagnostic information. This process typically includes three main stages: measurement, analysis, and interpretation, each of which is critically important for obtaining accurate and useful results.

Measurement

Analysis

Interpretation

Measurement Stage: Sensors as Window into Vibration World

Sensors are a critically important first link in the vibration diagnostic chain. Mainly accelerometers are used - devices installed on equipment to capture mechanical vibrations and convert them into electrical signals. The quality and characteristics of sensors directly affect the accuracy and reliability of the entire diagnostic process.

Modern accelerometers are divided into several main types:

Piezoelectric

Most common type. Have wide frequency range (up to 50 kHz), high sensitivity and stability. Ideal for most industrial applications.

IEPE (ICP)

Piezoelectric sensors with built-in electronics. Provide low noise level and simple connection. Require power from measuring instrument.

MEMS

Microelectromechanical sensors. Compact, inexpensive, shock resistant. Suitable for continuous monitoring and wireless systems.

Critically important sensor characteristics are:

- Sensitivity: Usually measured in mV/g or pC/g. High sensitivity allows detecting weak signals but may lead to overload with strong vibration.

- Frequency range: Determines the spectrum of frequencies that the sensor can accurately measure. For bearing diagnostics, a range up to 20-50 kHz may be required.

- Dynamic range: Ratio between maximum and minimum measurable level. Wide dynamic range allows measuring both weak and strong vibrations.

- Temperature stability: Important for industrial applications with wide operating temperature ranges.

Sensor Placement: Art and Science

Proper sensor placement is critically important for obtaining representative data. Sensors should be installed as close as possible to bearings, in directions of maximum structural stiffness, and with reliable mechanical attachment to ensure accurate vibration transmission.

Vibrometers: Quick Assessment of General Condition

Vibrometers are portable instruments that provide general vibration level measurement and are useful for quick equipment condition checks or for tracking long-term general machine condition trends. These instruments usually display one or several integral vibration parameters, such as RMS velocity or peak acceleration.

Modern vibrometers often include functions:

- Measurement in several frequency bands for rough problem localization

- Data storage for trend analysis

- Comparison with preset standards (ISO 20816, ISO 10816)

- Simple spectral visualization

- Wireless data transmission

| Parameter | Application | Typical Alarm Values | Frequency Band |

|---|---|---|---|

| Velocity RMS | General condition assessment | 2.8-11.2 mm/s | 10-1000 Hz |

| Acceleration Peak | Impact defects | 25-100 g | 1000-15000 Hz |

| Displacement Peak | Low-frequency problems | 25-100 μm | 2-200 Hz |

Vibration Analyzers: Deep Diagnostics

For deeper diagnostics and root cause identification of vibration, vibration analyzers or frequency analyzers are used. These complex instruments are specialized computers optimized for real-time vibration signal processing.

The basis of modern analyzer operation is Fast Fourier Transform (FFT), a mathematical algorithm that decomposes a complex time signal into its individual frequency components. This process generates a vibration spectrum - a graph showing vibration amplitude as a function of frequency.

Fourier transform converts time signal x(t) into frequency spectrum X(f)

Modern vibration analyzers offer many advanced functions:

- Multi-channel analysis: Simultaneous vibration measurement at several points for phase analysis

- High-resolution FFT: Up to 25,600 lines for detailed spectral analysis

- Time analysis: Capture and analysis of transient processes

- Envelope analysis: Extraction of modulating signals for bearing diagnostics

- Cepstral analysis: Detection of periodic structures in spectrum

- Orbital analysis: Visualization of shaft movement in space

Analyzer Selection Criteria

When choosing a vibration analyzer, it is important to consider not only technical characteristics but also ease of use, software quality, automatic result interpretation capabilities, and integration with enterprise management systems.

Time Waveform Analysis: Search for Transient Processes

Time waveform analysis is another valuable method, especially useful for detecting impacts, transients, and non-stationary phenomena that may not be visible in the frequency spectrum. This method allows observing the vibration signal in its "natural" form - as a function of time.

Key time analysis parameters include:

- Crest Factor: Ratio of peak value to RMS. High values indicate presence of impacts.

- Kurtosis: Statistical measure of distribution "sharpness". Increased kurtosis is often an early sign of developing bearing defects.

- Skewness: Measure of amplitude distribution asymmetry.

Integration of Various Analysis Methods

Most effective diagnostics is achieved by combining different analysis methods. Time analysis can reveal problem presence, spectral analysis can identify its type, and phase analysis can precisely localize the source.

Modern Trends in Diagnostic Equipment

Technology development leads to new capabilities in vibration diagnostics:

- Wireless monitoring systems: Sensor networks with autonomous power and wireless data transmission

- Artificial intelligence: Automatic defect pattern recognition and failure prediction

- Cloud platforms: Centralized data processing from multiple objects using large computational resources

- Mobile applications: Turning smartphones into portable vibration analyzers

- IIoT integration: Including vibration monitoring in Industrial Internet of Things systems

Implementation of these tools and methods, especially FFT analysis, prepares the ground for discussing advantages of having sophisticated analytical capabilities, ideally portable, for effective on-site diagnostics. Modern portable analyzers combine the power of stationary systems with convenience of field use, allowing comprehensive diagnostics directly at equipment.

Basic Measurement

Using simple vibrometers to assess general vibration level and determine need for further analysis

Spectral Analysis

Applying FFT analyzers to identify frequency components and determine defect type

In-depth Diagnostics

Using specialized methods (envelope analysis, cepstrum, orbits) for precise diagnosis of complex defects

Integrated Monitoring

Continuous monitoring with automatic diagnostics and AI-based prediction

The future of vibration diagnostics lies in creating intelligent systems capable of not only detecting and classifying defects but also predicting their development, optimizing maintenance planning, and integrating with general enterprise management systems to maximize operational efficiency.

1.6 The Power of Proactive Vibration Management: Benefits of Early Detection and Correction

Adopting a proactive approach to vibration management instead of the traditional reactive "repair after breakdown" approach represents a fundamental shift in maintenance philosophy. This approach not only prevents catastrophic failures but also optimizes the entire equipment lifecycle, transforming maintenance from a cost center into a source of competitive advantages.

Increased Equipment Service Life: Mathematics of Durability

Proactive vibration management offers many significant benefits, among which increased service life of equipment components stands out. Research shows that proper vibration management can increase bearing service life by 200-300%, seals by 150-200%, and overall machine service life by 50-100%.

These improvements are based on fundamental principles of material fatigue failure. According to Wöhler's equation, fatigue durability is inversely proportional to stress amplitude to a power that for most metals ranges from 3 to 10. This means that even a small reduction in vibration level can lead to substantial increase in service life.

where: N - number of cycles to failure, Δσ - stress amplitude, A and m - material constants

Improvement of Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a key production efficiency indicator that considers availability, performance, and quality. Proactive vibration management positively affects all three OEE components:

- Availability: Reduction of unplanned downtime through prevention of emergency failures

- Performance: Maintaining optimal operating parameters and speeds

- Quality: Reducing defects through stability of technological processes

Statistics show that enterprises implementing comprehensive vibration management programs achieve OEE improvements of 5-15%, which for a large manufacturing enterprise can mean additional profit of millions of dollars annually.

Economic Effect Calculation from OEE Improvement

For a production line worth $10 million with annual productivity of $50 million, a 10% OEE improvement gives additional profit of $5 million per year, which pays back investments in vibration monitoring system within several months.

Prevention of Serious and Costly Failures

One of the most significant benefits of proactive approach is prevention of serious and costly failures. Cascade failures, when breakdown of one component leads to damage of other system parts, can be especially destructive both financially and operationally.

A classic example is bearing failure in high-speed turbomachinery: bearing destruction can lead to rotor-stator contact, causing damage to blades, housing, shafts, and may even affect foundation. The cost of such cascade failure can be 50-100 times the cost of timely bearing replacement.

| Intervention Type | Cost | Downtime | Success Probability |

|---|---|---|---|

| Preventive maintenance | $1,000 | 2-4 hours | 95-98% |

| Planned repair | $5,000 | 8-16 hours | 90-95% |

| Emergency repair | $25,000 | 24-72 hours | 70-85% |

| Cascade failure | $100,000+ | 1-4 weeks | 50-70% |

Reduction of Operating Noise and Vibration

Noticeable reduction in operating noise is an additional benefit of effective vibration management. Noise in industrial environment not only creates discomfort for personnel but can also indicate technical problems, affect operator work accuracy, and create legal risks related to occupational safety requirements.

A 10 dB reduction in noise level is perceived by human ear as a two-fold decrease in loudness. For production facilities where noise level can exceed 90 dB, even small reduction can have significant effect on work comfort and personnel productivity.

Vibration Analysis as Foundation of Predictive Maintenance

Vibration analysis is the cornerstone of Predictive Maintenance (PdM) - a strategy aimed at anticipating breakdowns through continuous or periodic equipment condition monitoring. PdM represents evolution from reactive and preventive maintenance to intelligent, data-based approach.

Key principles of predictive maintenance include:

- Condition monitoring: Continuous or regular measurement of key parameters

- Trend analysis: Tracking changes over time to identify developing problems

- Forecasting: Using statistical models and machine learning to predict failures

- Optimization: Planning interventions at optimal time considering operational requirements

Economic Model of Predictive Maintenance

Research shows that predictive maintenance can reduce maintenance costs by 25-30%, increase uptime by 70-75%, and extend equipment service life by 20-40%.

Early Detection and Intervention Planning

Implementing vibration analysis program allows detecting problems at their initial stages when they do not yet affect performance but can already be detected using sensitive diagnostic methods. This reduces risk of unexpected shutdowns and optimizes maintenance planning.

The P-F (Potential-Functional failure) curve illustrates defect development over time:

Point P - Potential failure

Defect becomes detectable using diagnostic methods but does not yet affect functioning

Defect development

Gradual condition deterioration with possibility of planning intervention

Functional threshold

Defect begins to affect equipment performance

Point F - Functional failure

Equipment cannot perform its functions, emergency repair required

The P-F interval for different defect types can range from several days to several months, providing sufficient time for planning optimal intervention.

Direct Economic Benefits

This directly leads to reduced downtime and significant cost savings. Economic benefit analysis shows that every dollar invested in vibration monitoring system brings from 3 to 15 dollars in savings, depending on production type and equipment criticality.

Technological Requirements for Successful Implementation

To fully utilize these benefits, it is extremely important to have timely, accurate, and often on-site diagnostics. The ability to regularly and effectively conduct these checks is key to success of any proactive maintenance strategy.

Modern requirements for diagnostic equipment include:

- Portability: Ability to conduct measurements directly at equipment

- Accuracy: Capability to detect even weak signs of developing defects

- Analysis speed: Fast data processing for immediate decision making

- Ease of use: Intuitive interface for personnel of various qualifications

- Integration: Compatibility with existing management systems

Critical Success Factors

Success of proactive vibration management program depends not only on equipment quality but also on organizational factors: personnel training, creating appropriate procedures, integration with production planning, and management support.

Advanced portable tools allow quickly obtaining useful information, facilitating informed decision making and early intervention. These tools combine sophisticated analytical capabilities with practicality of field use, making advanced diagnostics accessible to a wide range of technical specialists.

The future of proactive vibration management lies in creating intelligent, self-learning systems that not only monitor current equipment condition but also optimize its operation in real time, adapting to changing operating conditions and production requirements. This opens the path to truly autonomous production systems capable of independently maintaining their optimal performance.

Conclusion: Path to Reliable and Efficient Production

Understanding and managing vibration in industrial equipment represents not just a technical necessity but a strategic foundation for achieving operational excellence in today's competitive world. Proper vibration diagnostics affects not only technical reliability of equipment but also economic efficiency, personnel safety, and environmental responsibility of the enterprise.

Investments in modern vibration monitoring and analysis systems pay back many times over through prevention of costly accidents, optimization of maintenance planning, and increased overall equipment effectiveness. The future of industrial production belongs to enterprises that can transform data about their equipment condition into competitive advantages.

0 Comments