Aprašymas

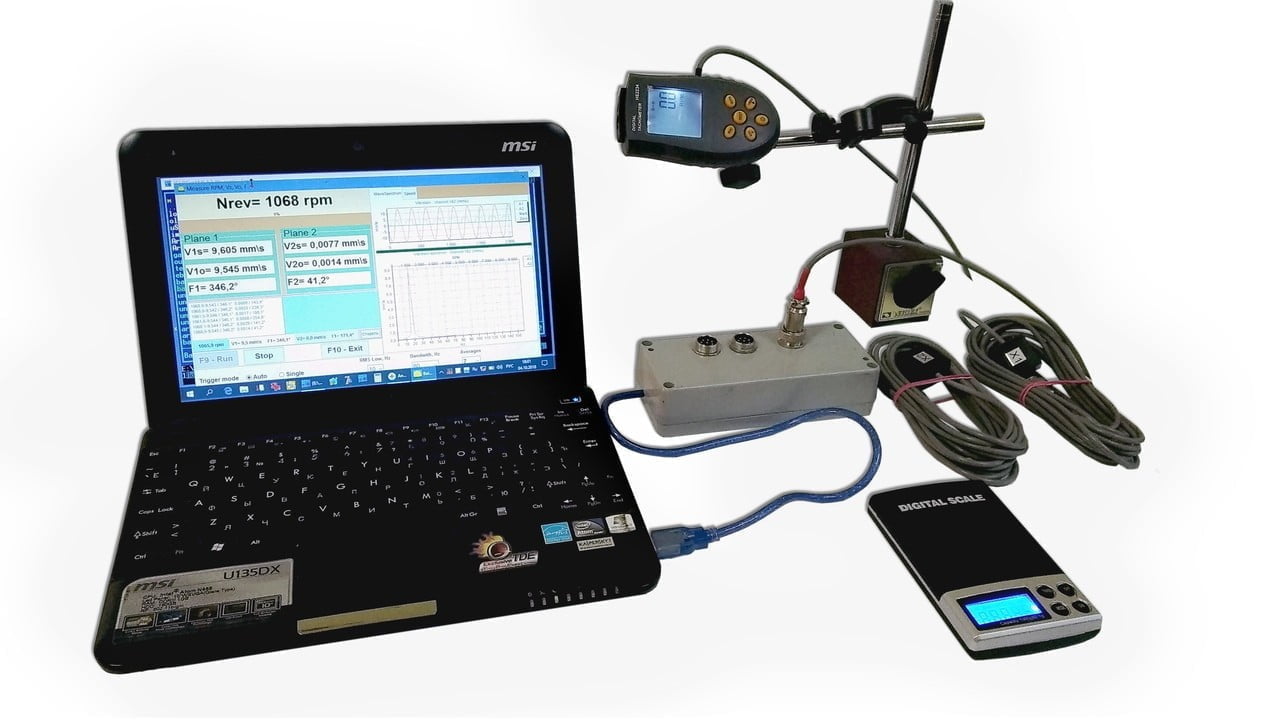

The Balanset-1A is equipped with 2 channels and is designed for dynamic balancing in two planes. This makes it suitable for a wide range of applications, including crushers, fans, mulchers, augers on combines, shafts, centrifuges, turbines, and many others. Its versatility in handling various types of rotors makes it an essential tool for many industries.

| Features/Components | Balanset-1A Full Kit | Balanset-1A OEM |

|---|---|---|

| Balanset-1A Interface Unit | ✅ | ✅ |

| Vibration Sensors (x2) | ✅ | ✅ |

| Software | ✅ | ✅ |

| Optical Sensor (Laser Tachometer) | ✅ | ✅ |

| Magnetic Stand | ✅ | ❌ |

| Scale | ✅ | ❌ |

| Plastic Transportation Case | ✅ | ❌ |

- “✅” indicates the component is included in the kit.

- “❌” indicates the component is not included in the kit.

Please Note:

Portable Balancer Overview

The Balanset-1A is a dual-channel vibration balancing and analysis device designed to work with a variety of rotor types including crushers, fans, mulchers, augers on combines, shafts, centrifuges, turbines and many others. It provides high precision and efficient balancing through a range of advanced features and technologies.

Features:

The Balanset-1A device offers a comprehensive range of functionalities for rotor balancing and vibration analysis:

Vibrometer Mode:

- Tachometer: Accurately measures rotational speed (RPM).

- Phase: Determines the vibration signal’s phase angle for precise analysis.

- 1x Vibration: Analyzes the fundamental frequency component.

- FFT Spectrum: Offers detailed frequency spectrum analysis of vibration signals.

- Overall Vibration: Monitors overall vibration levels.

- Measurement Log: Saves measurement data for further analysis.

Balancing Mode:

- Single Plane Balancing: Reduces vibration by balancing rotors in a single plane.

- Two Plane Balancing: Achieves dynamic balancing by balancing rotors in two planes.

- Polar Graph: Accurately places weights by visualizing imbalance in a polar graph.

- Restore Last Session: Resumes previous balancing sessions for convenience.

- Tolerance Calculator (ISO 1940): Computes acceptable balancing tolerances according to ISO 1940.

- Grinding Wheel Balancing: Utilizes 3 counterweights for balancing grinding wheels.

Charts:

- Overall Charts: Visual representation of overall vibration.

- 1x Charts: Displays vibration patterns of the fundamental frequency component.

- Harmonic Charts: Indicates the presence and impact of harmonic frequencies.

- Spectrum Charts: Graphical representation of the frequency spectrum for detailed analysis.

Additional Capabilities:

- Archive: Stores and retrieves past balancing sessions.

- Reports: Generates detailed reports of balancing outcomes.

- Re-balancing: Facilitates the repetition of the balancing process with saved data.

- Serial Production Balancing: Suitable for rotor balancing in serial production.

Balanset-1A also supports both Imperial and Metric systems, ensuring global compatibility and convenience.

Specifications:

- 2x Vibration Sensors (Vibro Accelerometers, cable length 4m, optional 10m)

- 1x Optical Sensor (Laser Tachometer, distance: 50 to 500mm, cable length 4m, optional 10m)

- 1x USB Interface Module with Software for PC Connection

- Software Capabilities: Measures vibration, phase angle, and calculates the value and angle of the correction mass.

Details:

- Number of Measurement Channels:

- Vibration: 2

- Rotational Speed: 1

- Range of RMS Vibration Velocity Measurement, mm/s: 0 to 80

- Frequency Range of RMS Vibration Velocity Measurement, Hz: 5 (10) to 550 (1000)

- Limits of Permissible Absolute Measurement Error of RMS Vibration Velocity at Base Frequency (80 Hz) and in the Working Frequency Range, mm/s: ±(0.1 + 0.1*Vi), where Vi is the measured RMS vibration velocity

- Number of Correction Planes for Balancing: 1 or 2

- Range of Rotational Speed Measurement, RPM: 250 – 90000

- Range of Vibration Phase Shift Measurement, Degrees: 0 to 360

- Limits of Permissible Absolute Measurement Error of Vibration Phase Shift, Degrees: ±2

- Accuracy: 5% of Full Scale

- Phase Angle Measurement Accuracy, Degrees: ±1

- Power: 7-20VDC input, 3.3V operating voltage (powered via USB port of a laptop)

- Weight: 4 KG