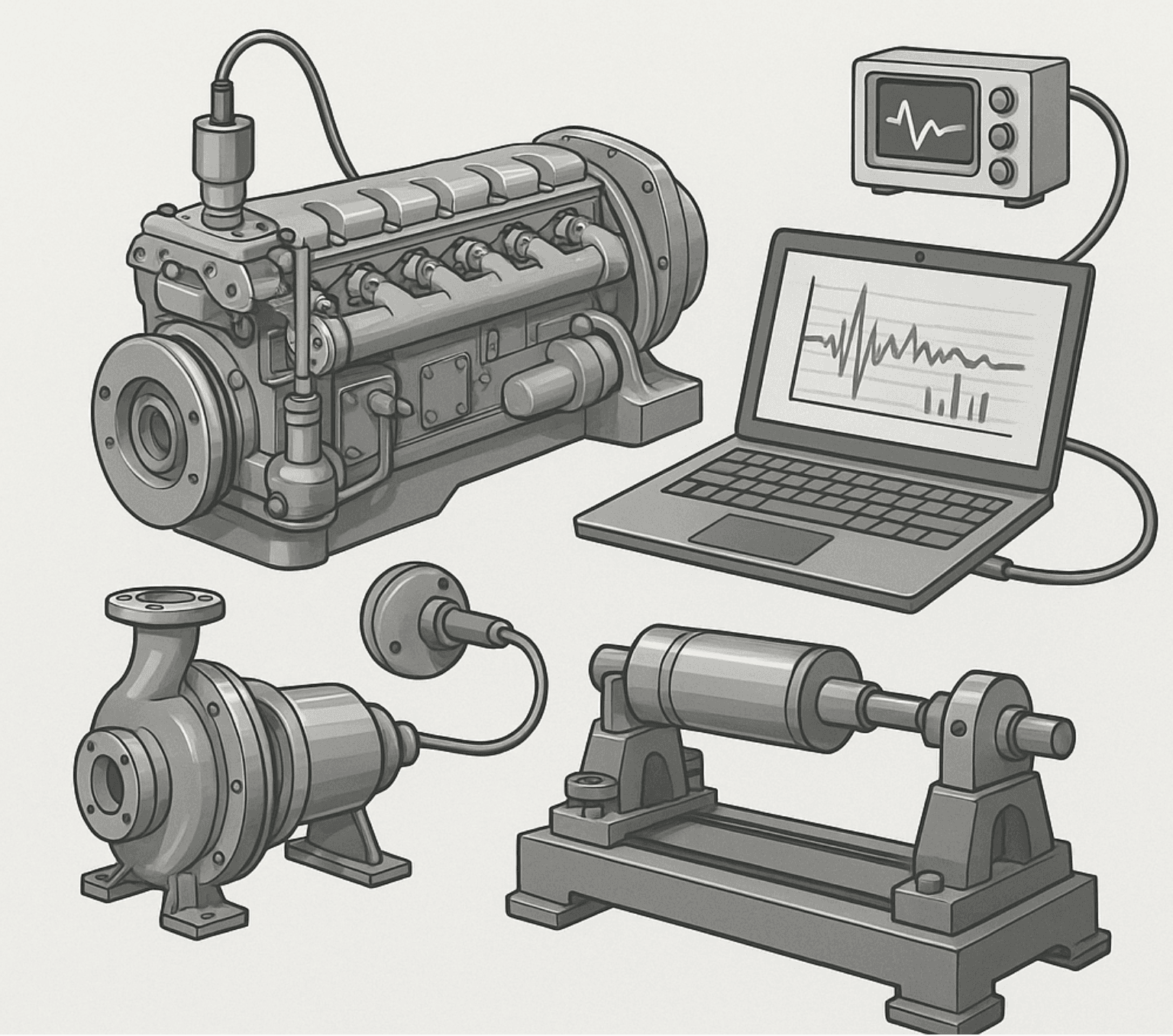

Comprehensive Guide to Vibration Diagnostics of Marine Equipment

Table of Contents

- 1. Fundamentals of Technical Diagnostics

- 2. Vibration Fundamentals

- 3. Vibration Measurement

- 4. Analysis and Processing of Vibration Signals

- 5. Vibration Control and Condition Monitoring

- 6. Diagnostics of Rotating Marine Equipment

- 7. Vibration Adjustment and Tuning

- 8. Future Perspectives in Vibration Diagnostics

1. Fundamentals of Technical Diagnostics

1.1 Technical Diagnostics Overview

Technical diagnostics represents a systematic approach to determining the current condition and predicting the future performance of marine equipment. Engineers use diagnostic techniques to identify developing faults before they lead to catastrophic failures, thereby ensuring operational safety and economic efficiency aboard vessels.

- Early detection of equipment deterioration

- Prediction of remaining useful life

- Optimization of maintenance schedules

- Prevention of unexpected failures

- Reduction of maintenance costs

Fundamental Principle of Technical Diagnostics

The fundamental principle of technical diagnostics relies on the correlation between equipment condition and measurable physical parameters. Engineers monitor specific diagnostic parameters that reflect the internal state of machinery. When equipment begins to deteriorate, these parameters change in predictable patterns, allowing specialists to detect and classify developing problems.

Diagnostic Terminology

Understanding diagnostic terminology forms the foundation for effective condition monitoring programs. Each term carries specific meaning that guides diagnostic decision-making:

| Term | Definition | Marine Application Example |

|---|---|---|

| Diagnostic Parameter | Measurable physical quantity that reflects equipment condition | Vibration velocity on pump bearing housing |

| Diagnostic Symptom | Specific pattern or characteristic in diagnostic data | Increased vibration at blade passing frequency in centrifugal pump |

| Diagnostic Sign | Recognizable indication of equipment condition | Sidebands around gear mesh frequency indicating tooth wear |

Recognition Algorithms and Diagnostic Models

Modern diagnostic systems employ sophisticated algorithms that automatically analyze collected data and identify equipment conditions. These algorithms use pattern recognition techniques to correlate measured parameters with known fault signatures.

Diagnostic Decision Process

Data Collection → Signal Processing → Pattern Recognition → Fault Classification → Severity Assessment → Maintenance Recommendation

Recognition algorithms process multiple diagnostic parameters simultaneously, considering their individual values and relationships. For instance, a diagnostic system monitoring a marine gas turbine might analyze vibration levels, temperature profiles, and oil analysis results together to provide comprehensive condition assessment.

Optimization of Controlled Parameters

Effective diagnostic programs require careful selection of monitored parameters and identified faults. Engineers must balance diagnostic coverage against practical constraints such as sensor costs, data processing requirements, and maintenance complexity.

- Sensitivity to fault development

- Reliability and repeatability

- Cost-effectiveness of measurement

- Relationship to critical failure modes

Maintenance Methods Evolution

Maritime industries have evolved through several maintenance philosophies, each offering different approaches to equipment care:

| Maintenance Type | Approach | Advantages | Limitations |

|---|---|---|---|

| Reactive | Fix when broken | Low upfront costs | High failure risks, unexpected downtime |

| Planned Preventive | Time-based maintenance | Predictable schedules | Over-maintenance, unnecessary costs |

| Condition-Based | Monitor actual condition | Optimized maintenance timing | Requires diagnostic expertise |

| Proactive | Eliminate failure causes | Maximum reliability | High initial investment |

Functional vs. Tester Diagnostics

Diagnostic approaches fall into two primary categories that serve different purposes in marine maintenance programs:

Functional Diagnostics monitors equipment during normal operation, collecting data while machinery performs its intended function. This approach provides realistic condition information but limits the types of tests possible.

Tester Diagnostics applies artificial excitation to equipment, often during shutdown periods, to evaluate specific characteristics like natural frequencies or structural integrity.

1.2 Vibration Diagnostics

Vibration diagnostics has emerged as the cornerstone of condition monitoring for rotating marine equipment. The technique leverages the fundamental principle that mechanical faults generate characteristic vibration patterns that trained analysts can interpret to assess equipment condition.

Vibration as Primary Diagnostic Signal

Rotating marine equipment inherently produces vibration through various mechanisms including unbalance, misalignment, bearing wear, and fluid flow disturbances. Healthy equipment exhibits predictable vibration signatures, while developing faults create distinct changes in these patterns.

Why Vibration Works for Marine Diagnostics

- All rotating machinery produces vibration

- Faults change vibration patterns predictably

- Non-intrusive measurement possible

- Early warning capability

- Quantitative condition assessment

Marine engineers utilize vibration monitoring because it provides early warning of developing problems while equipment continues operating. This capability proves especially valuable in marine applications where equipment failure can compromise vessel safety or strand ships at sea.

Methodology for Fault Detection

Effective vibration diagnostics requires systematic methodology that progresses from data collection through fault identification to severity assessment. The process typically follows these stages:

- Baseline Establishment: Record vibration signatures when equipment operates in good condition

- Trend Monitoring: Track changes in vibration levels over time

- Anomaly Detection: Identify deviations from normal patterns

- Fault Classification: Determine the type of developing problem

- Severity Assessment: Evaluate the urgency of maintenance needs

- Prognosis: Estimate remaining useful life

Equipment Condition States

Vibration diagnostics classifies marine equipment into distinct condition states based on measured parameters and observed trends:

| Condition State | Characteristics | Action Required |

|---|---|---|

| Good | Low, stable vibration levels | Continue normal operation |

| Acceptable | Elevated but stable levels | Increased monitoring frequency |

| Unsatisfactory | High levels or increasing trends | Plan maintenance intervention |

| Unacceptable | Very high levels or rapid changes | Immediate action required |

Types of Diagnostic Approaches

Parametric Diagnostics focuses on tracking specific vibration parameters such as overall levels, peak values, or frequency components. This approach works well for trend analysis and alarm generation.

Fault Diagnostics attempts to identify specific fault types by analyzing vibration signatures. Specialists look for characteristic patterns associated with bearing defects, unbalance, misalignment, or other common problems.

Preventive Diagnostics aims to detect fault initiation before symptoms become obvious through traditional monitoring. This approach often employs advanced signal processing techniques to extract subtle fault signatures from noise.

- Consistent measurement procedures

- Qualified personnel for data interpretation

- Integration with maintenance planning systems

- Management support for program investment

- Continuous improvement based on experience

Economic Benefits

Implementing vibration diagnostics in marine operations delivers significant economic benefits through reduced maintenance costs, improved equipment reliability, and enhanced operational efficiency. Studies show that comprehensive vibration monitoring programs typically provide return on investment ratios of 5:1 to 10:1.

2. Vibration Fundamentals

2.1 Physical Foundations of Mechanical Vibration

Understanding vibration fundamentals provides the theoretical foundation necessary for effective diagnostic work. Vibration represents the oscillatory motion of mechanical systems about their equilibrium positions, characterized by parameters that engineers measure and analyze to assess equipment condition.

Mechanical Oscillations: Core Parameters

Mechanical systems exhibit three fundamental types of vibratory motion, each providing different insights into equipment condition:

Velocity (v): v(t) = Aω cos(ωt + φ)

Acceleration (a): a(t) = -Aω² sin(ωt + φ)

Where A represents amplitude, ω denotes angular frequency, t indicates time, and φ shows phase angle.

Vibration Displacement measures the actual distance machinery moves from its neutral position. Marine engineers typically express displacement in micrometers (μm) or mils (0.001 inch). Displacement measurements prove most sensitive to low-frequency vibration such as unbalance in large, slow-running machinery.

Vibration Velocity quantifies the rate of displacement change, expressed in millimeters per second (mm/s) or inches per second (in/s). Velocity measurements provide broad frequency response and correlate well with the energy content of vibration, making them excellent for overall condition assessment.

Vibration Acceleration measures the rate of velocity change, typically expressed in meters per second squared (m/s²) or gravitational units (g). Acceleration measurements excel at detecting high-frequency vibration from sources like bearing defects or gear mesh problems.

Frequency Response Characteristics

| Parameter | Best for Frequencies | Marine Applications |

|---|---|---|

| Displacement | Below 10 Hz | Large diesel engines, slow turbines |

| Velocity | 10 Hz to 1 kHz | Most rotating machinery |

| Acceleration | Above 1 kHz | High-speed pumps, bearings, gears |

Statistical Measures of Vibration

Engineers use various statistical measures to characterize vibration signals and extract diagnostic information:

Peak Value represents the maximum instantaneous amplitude during a measurement period. Peak measurements help identify impact events or severe fault conditions that might not appear prominent in other measures.

RMS (Root Mean Square) Value provides the effective amplitude of vibration, calculated as the square root of the mean of squared instantaneous values. RMS measurements correlate with the energy content of vibration and serve as the standard for most condition monitoring applications.

Peak-to-Peak Value measures the total amplitude between positive and negative peaks. This parameter proves useful for displacement measurements and clearance calculations.

Crest Factor represents the ratio of peak to RMS values, indicating the "spikiness" of vibration signals. Healthy rotating machinery typically exhibits crest factors between 3 and 4, while bearing defects or impacts can drive crest factors above 6.

Rotary Equipment as Oscillatory Systems

Marine rotating equipment functions as complex oscillatory systems with multiple degrees of freedom, natural frequencies, and response characteristics. Understanding these system properties enables engineers to interpret vibration measurements correctly and identify developing problems.

Every rotating system possesses inherent stiffness, mass, and damping properties that determine its dynamic behavior. The rotor, shaft, bearings, foundation, and supporting structure all contribute to the overall system response.

Types of Vibrations in Marine Systems

Free Vibrations occur when systems oscillate at their natural frequencies after initial excitation. Marine engineers encounter free vibrations during equipment startup, shutdown, or following impact events.

Forced Vibrations result from continuous excitation at specific frequencies, typically related to rotational speed or flow phenomena. Most operational vibration in marine equipment represents forced vibration from various excitation sources.

Parametric Vibrations arise when system parameters vary periodically, such as changing stiffness in damaged gears or varying support conditions.

Self-Excited Vibrations develop when machinery creates its own excitation through mechanisms like oil whirl in journal bearings or aerodynamic instabilities in compressors.

- Synchronous: Vibration frequency locks to rotational speed (unbalance, misalignment)

- Asynchronous: Vibration frequency independent of speed (bearing defects, electrical problems)

Directional Characteristics

Vibration occurs in three perpendicular directions, each providing different diagnostic information:

Radial Vibration occurs perpendicular to the shaft axis and typically dominates in rotating equipment. Radial measurements detect unbalance, misalignment, bearing problems, and structural resonances.

Axial Vibration occurs parallel to the shaft axis and often indicates thrust bearing problems, coupling issues, or aerodynamic forces in turbomachinery.

Torsional Vibration represents twisting motion about the shaft axis, typically measured using specialized sensors or calculated from rotational speed variations.

Natural Frequencies and Resonance

Every mechanical system possesses natural frequencies where vibration amplification occurs. Resonance develops when excitation frequencies match or approach natural frequencies, potentially causing severe vibration and rapid equipment damage.

Marine engineers identify natural frequencies through impact testing, run-up/coast-down analysis, or analytical calculations. Understanding system natural frequencies helps explain vibration patterns and guides corrective actions.

Vibration Sources in Marine Equipment

Mechanical Sources include unbalance, misalignment, loose components, bearing defects, and gear problems. These sources typically produce vibration at frequencies related to rotational speed and component geometry.

Electromagnetic Sources in electrical machinery create vibration at twice line frequency and other electrical frequencies. Motor magnetic unbalance, rotor bar problems, and supply voltage imbalances generate characteristic electrical vibration signatures.

Aerodynamic/Hydrodynamic Sources result from fluid flow interactions in pumps, fans, compressors, and turbines. Blade passing frequencies, flow instabilities, and cavitation create distinctive vibration patterns.

- 1× RPM component from slight unbalance

- 2× line frequency from electrical magnetic forces

- Firing frequency from combustion forces

- High-frequency components from fuel injection system

2.2 Vibration Measurement Units and Standards

Standardized measurement units and evaluation criteria provide the foundation for consistent vibration assessment across marine operations. International standards establish measurement procedures, acceptance limits, and reporting formats that enable meaningful comparison of results.

Linear and Logarithmic Units

Vibration measurements employ both linear and logarithmic scales depending on the application and dynamic range requirements:

| Parameter | Linear Units | Logarithmic Units | Conversion |

|---|---|---|---|

| Displacement | μm, mils | dB ref 1 μm | dB = 20 log₁₀(x/x₀) |

| Velocity | mm/s, in/s | dB ref 1 mm/s | dB = 20 log₁₀(v/v₀) |

| Acceleration | m/s², g | dB ref 1 m/s² | dB = 20 log₁₀(a/a₀) |

Logarithmic units prove advantageous when dealing with wide dynamic ranges common in vibration measurements. The decibel scale compresses large variations into manageable ranges and emphasizes relative changes rather than absolute values.

International Standards Framework

Several international standards govern vibration measurement and evaluation in marine applications:

ISO 10816 Series provides guidelines for evaluating vibration measured on non-rotating parts of machinery. This standard establishes vibration zones (A, B, C, D) corresponding to different condition states.

ISO 7919 Series covers vibration measurement on rotating shafts, particularly relevant for large marine propulsion systems and turbomachinery.

ISO 14694 addresses vibration condition monitoring and diagnostics of machines, providing guidance on measurement procedures and data interpretation.

ISO 10816 Vibration Zones

| Zone | Condition | Typical Velocity RMS | Recommended Action |

|---|---|---|---|

| A | Good | 0.28 - 1.12 mm/s | No action required |

| B | Acceptable | 1.12 - 2.8 mm/s | Continue monitoring |

| C | Unsatisfactory | 2.8 - 7.1 mm/s | Plan maintenance |

| D | Unacceptable | >7.1 mm/s | Immediate action |

Machine Classification Criteria

Standards classify machinery based on several characteristics that influence vibration limits and measurement requirements:

Power Rating: Small machines (up to 15 kW), medium machines (15-75 kW), and large machines (above 75 kW) have different vibration tolerances reflecting their construction and support systems.

Speed Range: Slow-speed machines (under 600 RPM), medium-speed machines (600-12,000 RPM), and high-speed machines (above 12,000 RPM) exhibit different vibration characteristics and require appropriate measurement approaches.

Support System Stiffness: Standards distinguish between "rigid" and "flexible" mounting systems based on the relationship between machine operating speed and support system natural frequencies.

- Rigid: First support natural frequency > 2 × operating frequency

- Flexible: First support natural frequency < 0.5 × operating frequency

Measurement Points and Procedures

Standardized measurement procedures ensure consistent and comparable results across different equipment and operating conditions. Key considerations include:

Measurement Locations: Standards specify measurement points on bearing housings, closest to the main bearings, in directions that capture the primary vibration modes.

Operating Conditions: Measurements should occur during normal operating conditions at rated speed and load. Transient conditions during startup or shutdown require separate evaluation.

Measurement Duration: Sufficient measurement time ensures stable readings and captures any cyclic variations in vibration levels.

Evaluation Criteria and Limits

Standards provide vibration limits based on machine type, size, and mounting conditions. These limits represent boundaries between acceptable and unacceptable vibration levels, guiding maintenance decisions.

Evaluation criteria consider both absolute vibration levels and trends over time. Slowly increasing vibration may indicate developing problems even when absolute levels remain within acceptable limits.

3. Vibration Measurement

3.1 Vibration Measurement Methods

Effective vibration measurement requires understanding both the physical principles behind different measurement approaches and their practical applications in marine environments. Engineers select measurement methods based on equipment characteristics, diagnostic objectives, and operational constraints.

Kinematic vs. Dynamic Measurement Principles

Kinematic Measurement focuses on motion parameters (displacement, velocity, acceleration) without considering the forces that produce this motion. Most vibration sensors operate on kinematic principles, measuring the motion of surfaces relative to fixed reference frames.

Dynamic Measurement considers both motion and the forces that create vibration. Dynamic measurements prove valuable for understanding excitation sources and system response characteristics, particularly during diagnostic testing.

Absolute vs. Relative Vibration

The distinction between absolute and relative vibration measurements proves critical for proper sensor selection and data interpretation:

Absolute Vibration measures motion relative to a fixed reference frame (typically earth-fixed coordinates). Accelerometers and velocity sensors mounted on bearing housings provide absolute vibration measurements that reflect the motion of stationary components.

Relative Vibration measures motion between two components, typically shaft motion relative to bearing housings. Proximity probes provide relative measurements that directly indicate shaft dynamic behavior within bearing clearances.

Absolute vs. Relative Measurement Applications

| Measurement Type | Best Applications | Limitations |

|---|---|---|

| Absolute | General machinery monitoring, structural vibration | Cannot directly measure shaft motion |

| Relative | Large turbomachinery, critical rotating equipment | Requires shaft access, expensive installation |

Contact vs. Non-Contact Methods

Contact Methods require physical connection between sensor and vibrating surface. These methods include accelerometers, velocity sensors, and strain gauges that mount directly on equipment structures.

Contact sensors offer several advantages:

- High sensitivity and accuracy

- Broad frequency response

- Established measurement procedures

- Cost-effective solutions

Non-Contact Methods measure vibration without physical connection to the monitored equipment. Proximity probes, laser vibrometers, and optical sensors provide non-contact measurements.

Non-contact sensors excel in applications involving:

- High-temperature environments

- Rotating surfaces

- Hazardous locations

- Temporary measurements

3.2 Technical Vibration Measurement Equipment

Modern vibration measurement systems incorporate sophisticated sensor technologies and signal processing capabilities that enable accurate data collection in challenging marine environments. Understanding sensor characteristics and limitations ensures proper application and reliable results.

Sensor Characteristics and Performance

All vibration sensors exhibit characteristic performance parameters that define their capabilities and limitations:

Amplitude-Frequency Response describes how sensor output varies with input frequency at constant amplitude. Ideal sensors maintain flat response across their operating frequency range.

Phase-Frequency Response indicates phase shift between input vibration and sensor output as a function of frequency. Phase response becomes critical for applications involving multiple sensors or timing measurements.

Dynamic Range represents the ratio between maximum and minimum measurable amplitudes. Marine applications often require wide dynamic range to handle both low background vibration and high fault-related signals.

Signal-to-Noise Ratio compares useful signal strength to unwanted noise, determining the smallest vibration levels that sensors can reliably detect.

Proximity Probes (Eddy Current Sensors)

Proximity probes use eddy current principles to measure the distance between probe tip and conductive targets, typically rotating shafts. These sensors excel at measuring relative shaft motion within bearing clearances.

- High-frequency oscillator generates electromagnetic field

- Eddy currents form in nearby conductive surfaces

- Target distance changes alter eddy current patterns

- Electronics convert impedance changes to voltage output

Key characteristics of proximity probes include:

- DC response (can measure static displacement)

- High resolution (typically 0.1 μm or better)

- No mechanical contact with shaft

- Temperature stability

- Linear output over operating range

Velocity Sensors (Seismic Transducers)

Velocity sensors utilize electromagnetic induction principles, containing a magnetic mass suspended within a coil. Relative motion between mass and coil generates voltage proportional to velocity.

Velocity sensors offer several advantages for marine applications:

- Self-generating (no external power required)

- Broad frequency response (typically 10-1000 Hz)

- Robust construction

- Direct velocity output (ideal for ISO standards)

Limitations include:

- Limited low-frequency response

- Temperature sensitivity

- Magnetic field interference

- Relatively large size and weight

Accelerometers

Accelerometers represent the most versatile vibration sensors, using piezoelectric, piezoresistive, or capacitive technologies to measure acceleration. Piezoelectric accelerometers dominate marine applications due to their excellent performance characteristics.

Piezoelectric Accelerometers generate electrical charge proportional to applied force when crystalline materials experience mechanical stress. Common piezoelectric materials include natural quartz and synthetic ceramics.

Accelerometer Performance Comparison

| Type | Frequency Range | Sensitivity | Best Applications |

|---|---|---|---|

| General Purpose | 1 Hz - 10 kHz | 10-100 mV/g | Routine monitoring |

| High Frequency | 5 Hz - 50 kHz | 0.1-10 mV/g | Bearing diagnostics |

| High Sensitivity | 0.5 Hz - 5 kHz | 100-1000 mV/g | Low-level measurements |

Key accelerometer selection criteria include:

- Frequency range matching application requirements

- Sensitivity appropriate for expected vibration levels

- Environmental rating for temperature and humidity

- Mounting method compatibility

- Cable connector type and sealing

Sensor Mounting Methods

Proper sensor mounting ensures accurate measurements and prevents sensor damage. Different mounting methods provide varying frequency response and measurement fidelity:

Stud Mounting provides the highest frequency response and best accuracy by rigidly connecting sensors to measured surfaces through threaded studs.

Adhesive Mounting offers convenience for temporary measurements while maintaining good frequency response up to several kilohertz.

Magnetic Mounting enables quick sensor placement on ferromagnetic surfaces but limits frequency response due to mounting resonance.

Probe/Stinger Mounting allows measurements on difficult-to-access locations but further reduces frequency response.

Signal Conditioning Equipment

Vibration sensors require signal conditioning to convert raw sensor outputs into usable measurement signals. Signal conditioning systems provide power, amplification, filtering, and signal conversion functions.

Charge Amplifiers convert the high-impedance charge output of piezoelectric accelerometers into low-impedance voltage signals suitable for transmission over long cables.

Voltage Amplifiers boost low-level sensor outputs to levels required for analog-to-digital conversion while providing filtering and signal conditioning functions.

IEPE (Integrated Electronics Piezo-Electric) Systems incorporate built-in electronics within sensors, simplifying installation and improving noise immunity through constant-current excitation.

Data Acquisition Systems

Modern vibration measurement systems integrate sensors, signal conditioning, and data processing in sophisticated packages designed for marine environments. These systems provide automated data collection, analysis, and reporting capabilities.

Key features of marine vibration data acquisition systems include:

- Multi-channel simultaneous sampling

- Programmable gain and filtering

- Environmental protection (IP65 or better)

- Battery operation capability

- Wireless data transmission

- Integration with vessel systems

Calibration and Verification

Regular calibration ensures measurement accuracy and traceability to national standards. Marine vibration programs require systematic calibration procedures that account for harsh operating environments.

Primary Calibration uses precision vibration calibrators that provide known acceleration levels at specific frequencies. Laboratory-grade calibrators achieve uncertainties below 1%.

Field Verification employs portable calibration sources to verify sensor and system performance without removing equipment from service.

Back-to-Back Comparison compares readings from multiple sensors measuring the same vibration source, identifying sensors that drift outside acceptable tolerances.

- Annual laboratory calibration for critical systems

- Quarterly field verification checks

- Before/after calibration for important measurements

- Calibration following sensor damage or repair

4. Analysis and Processing of Vibration Signals

4.1 Types of Vibration Signals

Understanding different vibration signal types enables marine engineers to select appropriate analysis methods and correctly interpret diagnostic results. Equipment faults produce characteristic signal patterns that trained analysts recognize and classify.

Harmonic and Periodic Signals

Pure Harmonic Signals represent the simplest vibration form, characterized by sinusoidal motion at a single frequency. While rare in practical machinery, harmonic analysis forms the foundation for understanding more complex signals.

Where: A = amplitude, f = frequency, φ = phase

Polyharmonic Signals contain multiple frequency components with exact harmonic relationships. Rotating machinery commonly produces polyharmonic signals due to geometric periodicities and nonlinear forces.

Quasi-polyharmonic Signals exhibit nearly periodic behavior with slight frequency variations over time. These signals result from speed variations or modulation effects in machinery.

- 1st order: Primary firing frequency

- 2nd order: Secondary combustion effects

- Higher orders: Valve events and mechanical resonances

Modulated Signals

Modulation occurs when one signal parameter varies according to another signal, creating complex waveforms that carry diagnostic information about multiple fault sources.

Amplitude Modulation (AM) results when signal amplitude varies periodically. Common causes include:

- Bearing outer race defects

- Gear tooth wear patterns

- Electrical supply variations

- Shaft bow or runout

Where: m = modulation depth, f_m = modulation frequency, f_c = carrier frequency

Frequency Modulation (FM) occurs when signal frequency varies periodically, often indicating:

- Speed variations

- Coupling problems

- Load fluctuations

- Drive system instabilities

Phase Modulation (PM) involves periodic phase changes that can indicate timing variations or mechanical play in drive systems.

Transient and Impact Signals

Impulsive Signals represent short-duration, high-amplitude events that excite multiple system resonances. Rolling element bearing defects commonly produce impulsive signals as damaged surfaces impact during rotation.

Impact signals exhibit characteristic features:

- High crest factors (>6)

- Broad frequency content

- Rapid amplitude decay

- Periodic repetition rates

Beat Signals result from interference between closely spaced frequencies, creating periodic amplitude variations. Beat patterns often indicate:

- Multiple rotating elements

- Gear mesh interactions

- Electrical frequency mixing

- Structural resonance coupling

Random and Stochastic Signals

Stationary Random Signals exhibit statistical properties that remain constant over time. Turbulent flow noise and electrical interference often produce stationary random vibration.

Non-Stationary Random Signals show time-varying statistical characteristics, common in:

- Cavitation phenomena

- Bearing surface roughness effects

- Aerodynamic turbulence

- Gear mesh variations

Amplitude-Modulated Random Signals combine periodic modulation with random carrier signals, characteristic of advanced bearing degradation where random impacts become amplitude-modulated by geometric defect frequencies.

4.2 Signal Analysis Methods

Effective vibration analysis requires appropriate signal processing techniques that extract diagnostic information while suppressing noise and irrelevant components. Marine engineers select analysis methods based on signal characteristics and diagnostic objectives.

Time Domain Analysis

Waveform Analysis examines raw vibration signals in the time domain to identify signal characteristics not apparent in frequency analysis. Time waveforms reveal:

- Impact timing and repetition rates

- Modulation patterns

- Signal asymmetry

- Transient events

Statistical Analysis applies statistical measures to characterize signal properties:

Statistical Parameters for Vibration Analysis

| Parameter | Formula | Diagnostic Significance |

|---|---|---|

| RMS | √(Σx²/N) | Overall energy content |

| Crest Factor | Peak/RMS | Signal spikiness |

| Kurtosis | E[(x-μ)⁴]/σ⁴ | Impact detection |

| Skewness | E[(x-μ)³]/σ³ | Signal asymmetry |

Kurtosis proves particularly valuable for bearing diagnostics, as healthy bearings typically exhibit kurtosis values near 3.0 while developing defects drive kurtosis above 4.0.

Frequency Domain Analysis

Fourier Transform Principles enable conversion between time and frequency domains, revealing frequency components not visible in time waveforms. The Discrete Fourier Transform (DFT) processes digital signals:

Fast Fourier Transform (FFT) algorithms efficiently compute DFT for power-of-two length signals, making real-time spectral analysis practical in marine applications.

FFT analysis provides several key benefits:

- Identifies specific fault frequencies

- Tracks changes in frequency components

- Separates multiple vibration sources

- Enables comparison with established patterns

Digital Signal Processing Considerations

Analog-to-Digital Conversion transforms continuous vibration signals into discrete digital samples for computer processing. Key parameters include:

Sampling Rate: Must exceed twice the highest frequency of interest (Nyquist criterion) to avoid aliasing distortion.

Aliasing Prevention requires anti-aliasing filters that remove frequency components above the Nyquist frequency before sampling.

Windowing Functions minimize spectral leakage when analyzing non-periodic signals or signals with finite duration:

| Window Type | Best Application | Characteristics |

|---|---|---|

| Rectangular | Transient signals | Best frequency resolution |

| Hanning | General purpose | Good compromise |

| Flat-top | Amplitude accuracy | Best amplitude precision |

| Kaiser | Variable requirements | Adjustable parameters |

Filtering Techniques

Filters isolate specific frequency bands for focused analysis and remove unwanted signal components that could interfere with diagnostic interpretation.

Low-Pass Filters remove high-frequency components, useful for eliminating noise and focusing on low-frequency phenomena like unbalance and misalignment.

High-Pass Filters eliminate low-frequency components, helpful for removing the influence of unbalance when analyzing bearing and gear defects.

Band-Pass Filters isolate specific frequency bands, enabling analysis of individual machinery components or failure modes.

Tracking Filters follow specific frequency components as machinery speeds change, particularly useful for analyzing order-related vibration during startup and shutdown.

Advanced Analysis Techniques

Envelope Analysis extracts modulation information from high-frequency signals, particularly effective for rolling element bearing diagnostics. The technique involves:

- Band-pass filtering around bearing resonance frequencies

- Amplitude demodulation (envelope extraction)

- Low-pass filtering the envelope signal

- FFT analysis of the envelope

Cepstrum Analysis detects periodic components in frequency spectra, useful for identifying gear mesh sidebands and harmonic families that indicate specific fault conditions.

Order Tracking analyzes vibration components as multiples of rotational speed, essential for machinery operating at variable speeds. Order analysis maintains constant resolution in the order domain regardless of speed variations.

Coherence Analysis measures the linear relationship between two signals as a function of frequency, helping identify vibration transmission paths and coupling between machinery components.

- Identifying vibration transmission paths

- Validating measurement quality

- Assessing coupling between machines

- Evaluating isolation effectiveness

4.3 Technical Equipment for Vibration Analysis

Modern marine vibration analysis relies on sophisticated instruments that combine multiple analysis capabilities in portable, ruggedized packages suitable for shipboard use. Equipment selection depends on application requirements, environmental conditions, and operator expertise levels.

Vibration Meters and Analyzers

Simple Vibration Meters provide basic overall vibration measurements without frequency analysis capabilities. These instruments serve routine monitoring applications where trending overall levels suffices for condition assessment.

Octave Band Analyzers divide the frequency spectrum into standard octave or fraction-octave bands, providing frequency information while maintaining simplicity. Marine applications commonly use 1/3-octave analysis for noise and vibration assessment.

Narrow-Band Analyzers offer high frequency resolution using FFT processing, enabling detailed spectral analysis for diagnostic applications. These instruments form the backbone of comprehensive vibration programs.

Analyzer Comparison

| Analyzer Type | Frequency Resolution | Analysis Speed | Best Applications |

|---|---|---|---|

| Overall | None | Very Fast | Simple monitoring |

| 1/3 Octave | Proportional | Fast | General assessment |

| FFT | Constant | Moderate | Detailed diagnosis |

| Zoom FFT | Very High | Slow | Precise analysis |

Portable vs. Permanent Systems

Portable (Off-Line) Systems offer flexibility for periodic measurements across multiple machines. Benefits include:

- Lower per-machine cost

- Measurement flexibility

- Multi-machine coverage

- Detailed analysis capabilities

Limitations of portable systems:

- Manual measurement requirements

- Limited continuous monitoring

- Operator skill dependence

- Potential for missed events

Permanent (On-Line) Systems provide continuous monitoring of critical machinery with automatic data collection and alarm generation.

Advantages of permanent systems:

- Continuous monitoring capability

- Automatic alarm generation

- Consistent measurement conditions

- Historical data collection

Virtual Instrumentation

Virtual instruments combine general-purpose hardware with specialized software to create flexible analysis systems. This approach offers several advantages for marine applications:

- Customizable analysis functions

- Easy software updates

- Integration with vessel systems

- Cost-effective expansion

Virtual instrumentation typically employs:

- Commercial data acquisition hardware

- Standard computer platforms

- Specialized analysis software

- Custom user interfaces

Monitoring System Architecture

Comprehensive marine vibration monitoring systems integrate multiple components in hierarchical architectures that accommodate various equipment types and monitoring requirements.

Local Processing Units collect data from multiple sensors, perform initial processing, and communicate with central systems. These units provide distributed intelligence and reduce communication bandwidth requirements.

Central Monitoring Stations receive data from local units, perform advanced analysis, generate reports, and interface with vessel management systems.

Remote Access Capabilities enable shore-based experts to access shipboard monitoring systems for technical support and advanced diagnostics.

- Centralized data management

- Consistent analysis procedures

- Automated reporting

- Expert system support

Data Management Systems

Effective vibration programs require robust data management systems that store, organize, and retrieve measurement data for analysis and reporting purposes.

Database Design considerations include:

- Measurement data storage

- Equipment hierarchy definition

- Analysis results archiving

- User access control

Data Compression techniques reduce storage requirements while preserving diagnostic information. Common approaches include:

- Spectral data reduction

- Statistical parameter extraction

- Trend data compression

- Exception-based storage

5. Vibration Control and Condition Monitoring

5.1 Acceptance Testing and Quality Control

Vibration acceptance testing establishes baseline performance standards for new marine equipment and verifies compliance with specifications before entering service. These procedures protect against manufacturing defects and installation problems that could compromise equipment reliability.

Input/Output Vibration Control Methods

Systematic vibration control during equipment commissioning ensures proper installation and initial performance. Control methods encompass both pre-service verification and performance validation procedures.

Pre-Installation Testing verifies equipment condition before shipboard installation:

- Factory acceptance testing

- Transportation damage assessment

- Receiving inspection procedures

- Storage condition verification

Installation Verification confirms proper mounting, alignment, and system integration:

- Foundation compliance checking

- Alignment tolerance verification

- Piping stress assessment

- Electrical connection validation

Manufacturing and Installation Defect Detection

Vibration analysis effectively identifies common manufacturing and installation problems that traditional inspection methods might miss. Early detection prevents progressive damage and costly failures.

Manufacturing Defects detectable through vibration analysis include:

- Rotor balance quality deviations

- Bearing installation problems

- Machining tolerance violations

- Assembly alignment errors

Installation Defects commonly revealed by vibration testing:

- Soft foot conditions

- Coupling misalignment

- Piping strain

- Foundation resonances

Technical Standards and Specifications

Marine equipment vibration acceptance relies on established technical standards that define measurement procedures, evaluation criteria, and acceptance limits for various machinery types.

| Standard | Scope | Key Requirements |

|---|---|---|

| ISO 10816-1 | General machinery | Vibration evaluation zones |

| ISO 10816-6 | Reciprocating machines | RMS velocity limits |

| ISO 8528-9 | Generating sets | Load-dependent limits |

| API 610 | Centrifugal pumps | Shop test requirements |

Equipment Break-In Procedures

New marine equipment requires systematic break-in procedures that allow components to wear-in gradually while monitoring for abnormal conditions. Vibration monitoring during break-in provides early warning of potential problems.

Break-In Monitoring Phases:

- Initial startup verification

- Low-load operation assessment

- Progressive loading evaluation

- Full-load performance confirmation

- Extended operation validation

During break-in, engineers expect gradual changes in vibration characteristics as components settle and wear patterns establish. Sudden changes or continuously increasing levels indicate potential problems requiring investigation.

5.2 Vibration Monitoring Systems

Comprehensive vibration monitoring systems provide continuous surveillance of critical marine equipment, enabling early fault detection, trend analysis, and predictive maintenance planning. System design must accommodate the unique challenges of marine environments while providing reliable diagnostic capabilities.

Database Development and Management

Effective monitoring programs require robust database systems that organize equipment information, measurement data, and analysis results in accessible formats for decision-making.

Equipment Hierarchy Structure:

- Vessel level identification

- System classification (propulsion, electrical, auxiliary)

- Equipment type categorization

- Component level detail

- Measurement point definition

Data Types and Organization:

- Time waveform storage

- Frequency spectrum archiving

- Statistical parameter trends

- Operating condition records

- Maintenance history integration

Database Structure Example

Ship → Engine Department → Main Engine → Cylinder #1 → Exhaust Valve → Measurement Point A1

Each level contains specific information relevant to that hierarchy level, enabling efficient data organization and retrieval.

Equipment Selection and Program Development

Successful monitoring programs require systematic selection of equipment and measurement parameters based on criticality analysis, failure consequences, and diagnostic effectiveness.

Criticality Assessment Factors:

- Safety impact of equipment failure

- Economic consequences of downtime

- Spare parts availability

- Repair complexity and duration

- Historical failure frequency

Measurement Parameter Selection:

- Frequency ranges for expected faults

- Measurement directions (radial, axial)

- Sensor locations and quantities

- Sampling rates and data resolution

- Main engine (continuous monitoring)

- Main generators (continuous monitoring)

- Cargo pumps (periodic portable measurements)

- Auxiliary equipment (annual surveys)

Measurement Planning and Scheduling

Systematic measurement scheduling ensures consistent data collection while optimizing resource utilization and minimizing operational disruption.

Measurement Frequency Guidelines:

| Equipment Criticality | Measurement Frequency | Analysis Depth |

|---|---|---|

| Critical | Continuous/Daily | Detailed spectral analysis |

| Important | Weekly/Monthly | Trending with periodic analysis |

| Standard | Quarterly | Overall level trending |

| Non-critical | Annually | Basic condition assessment |

Alarm Level Setting and Baseline Establishment

Proper alarm configuration prevents both false alarms and missed fault conditions while providing timely notification of developing problems.

Baseline Establishment Procedures:

- Collect multiple measurements during good operating conditions

- Verify consistent operating parameters (load, speed, temperature)

- Calculate statistical parameters (mean, standard deviation)

- Establish alarm levels using statistical methods

- Document baseline conditions and assumptions

Alarm Level Setting Methods:

- Statistical methods (mean + 3σ)

- Standard-based limits (ISO zones)

- Experience-based thresholds

- Component-specific criteria

Trend Analysis and Change Detection

Trend analysis identifies gradual changes in equipment condition that indicate developing problems before they reach critical levels. Effective trend analysis requires consistent measurement procedures and proper statistical interpretation.

Trending Parameters:

- Overall vibration levels

- Specific frequency components

- Statistical measures (crest factor, kurtosis)

- Envelope parameters

Change Detection Methods:

- Statistical process control

- Regression analysis

- Cumulative sum techniques

- Pattern recognition algorithms

5.3 Technical and Software Systems

Modern marine vibration monitoring relies on integrated hardware and software systems that provide automated data collection, analysis, and reporting capabilities specifically designed for maritime applications.

Portable System Architecture

Portable vibration monitoring systems offer flexibility for comprehensive machinery surveys while maintaining professional analysis capabilities suitable for marine environments.

Core Components:

- Ruggedized data collector

- Multiple sensor types and cables

- Analysis and reporting software

- Database management system

- Communication interfaces

Marine-Specific Requirements:

- Intrinsically safe operation

- Temperature and humidity resistance

- Shock and vibration immunity

- Long battery life

- Intuitive user interface

- Lower cost per measurement point

- Measurement procedure flexibility

- Detailed analysis capabilities

- Multi-ship deployment

Permanent Monitoring Systems

Permanent monitoring systems provide continuous surveillance of critical equipment with automated data collection, processing, and alarm generation capabilities.

System Architecture:

- Distributed sensor networks

- Local processing units

- Central monitoring stations

- Communication infrastructure

- Remote access capabilities

Permanent System Benefits:

- Continuous condition monitoring

- Automatic alarm generation

- Consistent measurement conditions

- Historical data preservation

- Integration with vessel systems

Software Requirements and Capabilities

Monitoring software must provide comprehensive analysis capabilities while remaining accessible to marine engineers with varying levels of vibration expertise.

Essential Software Features:

- Multi-domain analysis (time, frequency, order)

- Automated fault detection algorithms

- Customizable reporting formats

- Trend analysis and prediction

- Database integration

User Interface Requirements:

- Graphical data presentation

- Expert system guidance

- Customizable dashboards

- Mobile device compatibility

- Multi-language support

Route-Based Data Collection

Route-based measurement systems optimize data collection efficiency by guiding technicians through predetermined measurement sequences while ensuring consistent procedures and complete coverage.

Route Development Process:

- Equipment identification and prioritization

- Measurement point selection and numbering

- Route optimization for efficiency

- Barcode or RFID tag installation

- Procedure documentation and training

Route-Based System Benefits:

- Consistent measurement procedures

- Complete equipment coverage

- Reduced measurement time

- Automatic data organization

- Quality assurance features

Route-Based Measurement Workflow

Route Planning → Equipment Tagging → Data Collection → Automatic Upload → Analysis → Reporting

Communication and Data Management

Modern marine monitoring systems require robust communication capabilities for data transfer, remote access, and integration with vessel management systems.

Communication Options:

- Ethernet networks for shipboard systems

- Wireless networks for portable devices

- Satellite communications for shore reporting

- USB and memory card transfers

Data Management Features:

- Automated backup systems

- Data compression algorithms

- Secure data transmission

- Cloud storage integration

6. Diagnostics of Rotating Marine Equipment

6.1 Vibration Characteristics of Machinery Components

Different machinery components produce characteristic vibration signatures that enable trained analysts to identify specific problems and assess their severity. Understanding these signatures forms the foundation of effective vibration diagnostics in marine applications.

Rolling Element Bearing Diagnostics

Rolling element bearings represent critical components in marine machinery, and their condition significantly impacts equipment reliability. Bearing defects produce distinctive vibration patterns that analysts can identify and track.

Bearing Defect Frequencies: Each bearing geometry generates specific fault frequencies when defects develop:

BPFO = (N × RPM × (1 - (d/D) × cos φ)) / 120

Ball Pass Frequency Inner Race (BPFI):

BPFI = (N × RPM × (1 + (d/D) × cos φ)) / 120

Ball Spin Frequency (BSF):

BSF = (RPM × D × (1 - (d/D)² × cos² φ)) / (240 × d)

Fundamental Train Frequency (FTF):

FTF = (RPM × (1 - (d/D) × cos φ)) / 120

Where: N = number of rolling elements, d = rolling element diameter, D = pitch diameter, φ = contact angle

- BPFO = 102.2 Hz (outer race defects)

- BPFI = 157.8 Hz (inner race defects)

- BSF = 67.3 Hz (ball defects)

- FTF = 11.4 Hz (cage defects)

Bearing Condition Assessment Stages:

- Stage 1 - Onset: Slight increase in high-frequency noise floor

- Stage 2 - Development: Discrete bearing frequencies appear

- Stage 3 - Progression: Harmonics and sidebands develop

- Stage 4 - Advanced: Subharmonics and modulation increase

- Stage 5 - Final: Broadband random vibration predominates

Plain Bearing (Journal Bearing) Analysis

Plain bearings in marine applications, particularly in large diesel engines and turbomachinery, exhibit different failure modes and vibration characteristics compared to rolling element bearings.

Common Plain Bearing Problems:

- Oil Whirl: Occurs at approximately 0.4-0.48× RPM

- Oil Whip: Frequency locks to first critical speed

- Bearing Wear: Increases synchronous vibration (1× RPM)

- Misalignment: Creates 2× RPM components

Gear System Diagnostics

Gear systems in marine applications include main reduction gears, auxiliary gearboxes, and various drive trains. Gear problems produce characteristic frequency patterns related to tooth meshing and load distribution.

Fundamental Gear Frequencies:

- Gear Mesh Frequency (GMF): Number of teeth × RPM ÷ 60

- Sideband Frequencies: GMF ± shaft frequencies

- Hunting Tooth Frequency: Related to tooth number relationships

Gear Fault Indicators:

- Increased GMF amplitude

- Sideband development around GMF

- Harmonic generation

- Modulation patterns

- Pinion frequency: 20 Hz

- Gear frequency: 6.87 Hz

- Mesh frequency: 460 Hz

- Sidebands at 460 ± 20 Hz and 460 ± 6.87 Hz indicate developing problems

Shaft and Rotor Dynamics

Shaft-related problems create vibration patterns that reflect the mechanical condition and dynamic behavior of rotating assemblies.

Common Shaft Problems:

- Unbalance: Predominant 1× RPM vibration

- Bow/Bent Shaft: 1× and 2× RPM components

- Coupling Problems: 2× RPM vibration

- Looseness: Multiple harmonics of RPM

Misalignment Types and Signatures:

| Misalignment Type | Primary Frequency | Characteristics |

|---|---|---|

| Parallel | 2× RPM | High radial vibration |

| Angular | 2× RPM | High axial vibration |

| Combined | 1× and 2× RPM | Mixed radial and axial |

Impeller and Flow-Related Vibration

Pumps, fans, and compressors generate vibration related to fluid flow patterns and impeller condition. These hydraulic or aerodynamic sources create distinctive frequency patterns.

Flow-Related Frequencies:

- Blade Pass Frequency (BPF): Number of blades × RPM ÷ 60

- Harmonics of BPF: Indicate flow disturbances

- Sub-synchronous Components: May indicate cavitation or recirculation

Pump-Specific Problems:

- Cavitation: Random high-frequency vibration

- Impeller Damage: Increased BPF and harmonics

- Recirculation: Low-frequency random vibration

- Flow Turbulence: Broadband vibration increase

6.2 Fault Detection and Identification

Systematic fault detection requires combining spectral analysis with time-domain techniques, statistical methods, and pattern recognition to identify developing problems and assess their severity accurately.

Spectral Analysis for Fault Detection

Frequency domain analysis provides the primary tool for identifying specific fault types by revealing characteristic frequency components associated with different failure modes.

Harmonic Analysis: Many machinery faults produce harmonic series that help identify the source and severity of problems:

- Unbalance: Predominantly 1× RPM with minimal harmonics

- Misalignment: Strong 2× RPM with potential 3× and 4× harmonics

- Looseness: Multiple harmonics (up to 10× RPM or higher)

- Rubs: Fractional harmonics (0.5×, 1.5×, 2.5× RPM)

Sideband Analysis: Modulation effects create sidebands around primary frequencies that indicate specific fault mechanisms:

- Gear tooth problems create sidebands around mesh frequency

- Bearing race defects modulate high-frequency resonances

- Electrical problems create sidebands around line frequency

Fault Frequency Identification Chart

| Fault Type | Primary Frequency | Additional Components | Diagnostic Notes |

|---|---|---|---|

| Unbalance | 1× RPM | Minimal harmonics | Phase relationship important |

| Misalignment | 2× RPM | Higher harmonics | Axial measurements critical |

| Bearing Defects | BPFI/BPFO/BSF | Harmonics and sidebands | Envelope analysis helpful |

| Gear Problems | GMF | Sidebands at shaft rates | Load-dependent changes |

Time-Domain Analysis Techniques

Time-domain analysis complements frequency analysis by revealing signal characteristics not apparent in spectral data, particularly for impulsive or transient phenomena.

Waveform Shape Analysis:

- Sinusoidal: Indicates simple periodic excitation (unbalance)

- Clipped/Truncated: Suggests impacts or clearance problems

- Modulated: Shows amplitude or frequency variations

- Random: Indicates turbulent or stochastic excitation

Statistical Parameters for Fault Detection:

- Crest Factor: Peak/RMS ratio indicates signal spikiness

- Kurtosis: Fourth-moment statistic sensitive to impacts

- Skewness: Third-moment statistic indicating asymmetry

- RMS Trending: Overall energy content changes

- Crest factor increase from 3.2 to 6.8

- Kurtosis rise from 3.1 to 12.4

- RMS levels relatively stable

Envelope Analysis for Bearing Diagnostics

Envelope analysis (amplitude demodulation) extracts modulation information from high-frequency signals, making it particularly effective for detecting rolling element bearing defects that create periodic impacts.

Envelope Analysis Process:

- Band-pass filter around structural resonance (typically 1-5 kHz)

- Apply envelope detection (Hilbert transform or rectification)

- Low-pass filter the envelope signal

- Perform FFT analysis on the envelope

- Identify bearing fault frequencies in envelope spectrum

Envelope Analysis Advantages:

- Enhanced sensitivity to early bearing faults

- Reduces interference from other vibration sources

- Provides clear bearing fault frequency identification

- Enables fault severity assessment

Advanced Pattern Recognition

Modern diagnostic systems employ sophisticated pattern recognition algorithms that automatically classify fault types and assess severity levels based on learned patterns and expert knowledge.

Machine Learning Approaches:

- Neural Networks: Learn complex fault patterns from training data

- Support Vector Machines: Classify faults using optimal decision boundaries

- Decision Trees: Provide logical fault identification procedures

- Fuzzy Logic: Handle uncertainty in fault classification

Expert Systems: Incorporate domain knowledge from experienced analysts to guide automated fault detection and provide diagnostic reasoning.

- Consistent fault identification

- Reduced analyst workload

- 24/7 monitoring capability

- Documented diagnostic reasoning

6.3 Fault Severity Assessment

Determining fault severity enables prioritization of maintenance actions and estimation of remaining equipment life, critical factors in marine operations where unplanned downtime can have severe consequences.

Quantitative Severity Metrics

Effective severity assessment requires quantitative metrics that relate vibration characteristics to actual component condition and remaining useful life.

Amplitude-Based Metrics:

- Fault frequency amplitude relative to baseline

- Rate of amplitude increase over time

- Ratio of fault frequency to overall vibration

- Comparison to established severity limits

Statistical Severity Indicators:

- Crest factor progression trends

- Kurtosis development patterns

- Envelope parameter changes

- Spectral distribution modifications

| Month | BPFO Amplitude | Crest Factor | Severity Level |

|---|---|---|---|

| 1 | 0.2 g | 3.4 | Early stage |

| 3 | 0.8 g | 4.2 | Developing |

| 5 | 2.1 g | 6.8 | Advanced |

| 6 | 4.5 g | 9.2 | Critical |

Prognostic Modeling

Prognostic models predict remaining useful life by analyzing current condition trends and applying physics-based or data-driven degradation models.

Trending Analysis Methods:

- Linear Regression: Simple trending for steady degradation

- Exponential Models: Accelerating degradation patterns

- Power Law Models: Variable degradation rates

- Polynomial Fitting: Complex degradation trajectories

Physics-Based Models: Incorporate fundamental degradation mechanisms to predict fault progression based on operating conditions and material properties.

Data-Driven Models: Use historical failure data and current measurements to predict remaining life without explicit physics modeling.

Maintenance Decision Support

Diagnostic results must translate into actionable maintenance recommendations that consider operational constraints, spare parts availability, and safety requirements.

Decision Factors:

- Current fault severity level

- Predicted degradation rate

- Operational consequences of failure

- Maintenance window availability

- Spare parts and resource availability

Recommended Actions by Severity:

| Severity Level | Recommended Action | Timeline |

|---|---|---|

| Good | Continue normal monitoring | Next scheduled measurement |

| Early Fault | Increase monitoring frequency | Monthly measurements |

| Developing | Plan maintenance intervention | Next available opportunity |

| Advanced | Schedule immediate maintenance | Within 2 weeks |

| Critical | Emergency shutdown if possible | Immediate |

- Port availability for maintenance

- Weather conditions for safe work

- Crew availability and expertise

- Cargo schedule impacts

7. Vibration Adjustment and Tuning

7.1 Shaft Alignment

Proper shaft alignment represents one of the most critical factors affecting marine equipment reliability and vibration levels. Misalignment creates excessive forces, accelerates wear, and produces characteristic vibration signatures that diagnostic systems readily detect.

Fundamentals of Shaft Alignment

Shaft alignment ensures that connected rotating elements operate with their centerlines coincident under normal operating conditions. Marine environments present unique challenges including thermal effects, hull deflection, and foundation settling that complicate alignment procedures.

Types of Misalignment:

- Parallel (Offset) Misalignment: Shaft centerlines remain parallel but displaced

- Angular Misalignment: Shaft centerlines intersect at an angle

- Combined Misalignment: Combination of parallel and angular conditions

- Axial Misalignment: Incorrect axial positioning between coupled components

Misalignment Effects on Vibration

| Misalignment Type | Primary Vibration Frequency | Direction | Additional Symptoms |

|---|---|---|---|

| Parallel | 2× RPM | Radial | 180° phase difference across coupling |

| Angular | 2× RPM | Axial | High axial vibration, coupling wear |

| Combined | 1× and 2× RPM | All directions | Complex phase relationships |

Detection of Static and Dynamic Misalignment

Static Misalignment refers to alignment conditions measured when equipment is not operating. Traditional alignment procedures focus on static conditions using dial indicators or laser alignment systems.

Dynamic Misalignment represents the actual operating alignment condition, which may differ significantly from static alignment due to thermal growth, foundation movement, and operational forces.

Vibration-Based Detection Methods:

- High 2× RPM vibration components

- Phase relationships across couplings

- Directional vibration patterns

- Load-dependent vibration changes

Measurement Methods and Accuracy Limitations

Modern marine alignment procedures employ laser-based measurement systems that provide superior accuracy and documentation compared to traditional dial indicator methods.

Laser Alignment System Advantages:

- Higher measurement accuracy (±0.001 inch typical)

- Real-time feedback during adjustment

- Automatic calculation of correction moves

- Digital documentation and reporting

- Reduced setup time and complexity

Measurement Accuracy Factors:

- Foundation stability during measurement

- Temperature stability

- Coupling flexibility effects

- Instrument calibration status

Soft Foot Detection and Correction

Soft foot conditions occur when machinery mounting feet don't make proper contact with foundation surfaces, creating variable support conditions that affect alignment and vibration characteristics.

Soft Foot Types:

- Parallel Soft Foot: Foot suspended above foundation

- Angular Soft Foot: Machine frame distortion

- Induced Soft Foot: Created by over-tightening bolts

- Springing Soft Foot: Foundation compliance issues

Detection Methods:

- Systematic bolt loosening and measurement

- Feeler gauge measurements

- Laser measurement of position changes

- Vibration analysis of mounting resonances

Thermal Growth Considerations

Marine equipment experiences significant temperature variations during operation that cause differential thermal expansion between connected components. Alignment procedures must account for these effects to achieve proper operating alignment.

Thermal Growth Factors:

- Material thermal expansion coefficients

- Operating temperature differences

- Foundation and structure expansion

- Ambient temperature variations

Thermal Growth Calculation:

Where: ΔL = length change, L = original length, α = expansion coefficient, ΔT = temperature change

7.2 Machine Balancing

Balancing eliminates or reduces unbalance forces that create vibration, bearing loads, and fatigue stresses in rotating marine equipment. Proper balancing significantly improves equipment reliability and reduces maintenance requirements.

Balancing Theory and Terminology

Mass Unbalance occurs when the center of mass of a rotating component doesn't coincide with its axis of rotation, creating centrifugal forces proportional to the square of rotational speed.

Where: F = force, m = unbalance mass, r = radius, ω = angular velocity

Types of Unbalance:

- Static Unbalance: Single heavy spot causing force in one plane

- Couple Unbalance: Equal masses in different planes creating moment

- Dynamic Unbalance: Combination of static and couple unbalance

- Quasi-static Unbalance: Unbalance that appears only during rotation

- G 0.4: Precision grinding machine spindles

- G 1.0: High-precision machine tool spindles

- G 2.5: High-speed marine equipment

- G 6.3: General marine machinery

- G 16: Large slow-speed marine engines

Critical Speed Considerations

Critical speeds occur when the rotational frequency coincides with natural frequencies of the rotor-bearing system, potentially causing dangerous resonance conditions that amplify unbalance forces.

Critical Speed Types:

- First Critical: First bending mode of rotor system

- Higher Criticals: Additional bending and torsional modes

- System Criticals: Foundation and support structure resonances

Operating Speed Guidelines:

- Rigid rotors: Operate below first critical (typically <50% of critical)

- Flexible rotors: Operate between criticals or above second critical

- Avoid sustained operation within ±15% of critical speeds

Balancing Methods and Procedures

Shop Balancing occurs on specialized balancing machines before equipment installation, providing controlled conditions and high accuracy.

Field Balancing balances equipment in its operating configuration, accounting for actual support conditions and system dynamics.

Single-Plane Balancing corrects static unbalance using one correction plane, suitable for disk-type rotors where length-to-diameter ratio is small.

Two-Plane Balancing addresses dynamic unbalance using correction masses in two planes, required for rotors with significant length-to-diameter ratios.

Balancing Procedure Overview

- Measure initial unbalance vibration

- Calculate trial mass requirements

- Install trial masses and measure response

- Calculate influence coefficients

- Determine final correction masses

- Install correction masses

- Verify final balance quality

7.3 Field Balancing Considerations

Field balancing in marine environments presents unique challenges that require specialized techniques and consideration of operational constraints specific to maritime applications.

Marine Environment Challenges

Shipboard balancing operations face several challenges not encountered in shore-based facilities:

- Vessel Motion: Sea conditions create background vibration that interferes with measurements

- Space Constraints: Limited access for balancing equipment and correction weight installation

- Operational Requirements: Difficulty shutting down critical systems for balancing

- Environmental Conditions: Temperature, humidity, and corrosive atmosphere effects

Motion Compensation Techniques:

- Measurement averaging over multiple vessel motion cycles

- Reference sensor techniques to subtract vessel motion

- Calm weather scheduling for critical balancing operations

- Harbor balancing when possible

Thermal Effects and Compensation

Marine equipment experiences significant thermal effects during operation that can create temporary unbalance conditions requiring careful analysis and compensation.

Thermal Unbalance Sources:

- Differential thermal expansion of rotor components

- Thermal distortion of rotor assemblies

- Temperature-dependent material properties

- Bearing clearance changes with temperature

Compensation Strategies:

- Balance at operating temperature when possible

- Apply temperature correction factors

- Use thermal modeling for correction calculations

- Consider steady-state vs. transient thermal effects

Coupling and Drive System Effects

Marine drive systems often include flexible couplings, gear reducers, and other components that affect balancing procedures and results.

Coupling Considerations:

- Flexible coupling damping effects

- Coupling unbalance contributions

- Phase relationships across couplings

- Coupling wear effects on balance

Multi-Stage System Balancing:

- Individual component balancing

- System-level optimization

- Sequential balancing procedures

- Interaction effects consideration

7.4 Balancing Equipment and Software

Modern marine balancing operations employ sophisticated portable equipment and software systems specifically designed for field use in challenging environments.

Portable Balancing Instruments

Marine balancing instruments must provide accurate measurements while withstanding harsh shipboard conditions including vibration, temperature extremes, and electromagnetic interference.

Instrument Requirements:

- Multi-channel vibration measurement capability

- Phase measurement accuracy better than ±1 degree

- Built-in signal processing and filtering

- Ruggedized construction for marine environments

- Battery operation for portable use

Advanced Features:

- Automatic influence coefficient calculation

- Multiple correction plane capabilities

- Trim balancing functions

- Historical data storage and trending

Software Capabilities and Requirements

Balancing software must provide comprehensive analysis capabilities while remaining accessible to marine engineers with varying levels of balancing expertise.

Essential Software Functions:

- Vector analysis and manipulation

- Influence coefficient calculation

- Correction mass optimization

- Balancing quality assessment

- Report generation and documentation

Advanced Capabilities:

- Modal balancing for flexible rotors

- Multi-speed balancing analysis

- Sensitivity analysis and uncertainty quantification

- Integration with condition monitoring systems

- User-friendly interface design

- Comprehensive help and guidance systems

- Integration with measurement hardware

- Customizable reporting formats

- Technical support availability

7.5 Alternative Vibration Reduction Methods

When balancing and alignment cannot adequately reduce vibration levels, alternative methods provide additional tools for achieving acceptable equipment operation in marine environments.

Source Modification Techniques

Reducing vibration at its source often provides the most effective and economical solution by eliminating the root cause rather than treating symptoms.

Design Modifications:

- Optimizing component geometry to reduce excitation forces

- Selecting operating speeds away from critical frequencies

- Improving manufacturing tolerances and balance quality

- Enhanced bearing and mounting system designs

Operational Modifications:

- Load optimization to minimize excitation

- Speed control to avoid resonance conditions

- Maintenance procedures to preserve balance and alignment

- Operating parameter optimization

System Stiffness and Damping Modifications

Altering the dynamic characteristics of mechanical systems can shift natural frequencies away from excitation frequencies or reduce response amplitudes through increased damping.

Stiffness Modifications:

- Foundation reinforcement to increase stiffness

- Structural bracing to modify natural frequencies

- Bearing housing modifications

- Piping support optimization

Damping Enhancement:

- Viscoelastic damping materials

- Friction damping devices

- Fluid damping systems

- Structural modifications to increase material damping

Vibration Isolation Systems

Isolation systems prevent vibration transmission between sources and sensitive areas, protecting both equipment and personnel from harmful vibration effects.

Isolation System Types:

- Passive Isolation: Springs, rubber mounts, air springs

- Active Isolation: Electronically controlled actuators

- Semi-Active: Variable-stiffness or damping systems

Marine Isolation Considerations:

- Seismic loading from vessel motion

- Corrosion resistance requirements

- Maintenance accessibility

- Thermal cycling effects

Resonance Control Methods

Resonance conditions can dramatically amplify vibration levels, making resonance identification and control critical for marine equipment reliability.

Resonance Identification:

- Impact testing to determine natural frequencies

- Operating deflection shape analysis

- Modal analysis techniques

- Run-up/coast-down testing

Control Strategies:

- Frequency shifting through stiffness modification

- Damping addition to reduce amplification

- Operating speed changes to avoid resonance

- Tuned mass dampers for narrow-band control

8. Future Perspectives in Vibration Diagnostics

8.1 Current Technology Trends

The field of marine vibration diagnostics continues evolving rapidly, driven by advances in sensor technology, signal processing capabilities, artificial intelligence, and integration with broader vessel management systems. Understanding these trends helps marine engineers prepare for future diagnostic capabilities and plan technology investments.

Advanced Sensor Technologies

Next-generation sensors offer enhanced capabilities that overcome traditional limitations while providing new measurement possibilities for marine applications.

Wireless Sensor Networks: Eliminate the need for extensive cabling while providing flexible sensor placement and reduced installation costs. Modern wireless sensors offer:

- Long battery life (5+ years typical)

- Robust communication protocols

- Edge computing capabilities

- Self-organizing network topology

- Encryption for data security