Crusher and Mill Balancing: Industrial Precision from Vibromera

Vibration in industrial crushers or mills is not just a technical feature. It's a harbinger of serious breakdowns that can shut down entire production lines. Vibromera, with offices in Porto (Portugal), offers advanced solutions to this problem throughout the European Union: mobile dynamic balancing services and the innovative portable Balanset-1A device for independent equipment maintenance.

Where Are Crushers and Mills Used?

Crushing and grinding equipment is the heart of many production processes. It is indispensable in various industries where material size reduction is critical for operational efficiency and product quality.

⛏️ Mining Industry

For crushing ore, coal, and aggregate materials. Essential for extracting valuable minerals and preparing raw materials for further processing.

♻️ Waste Processing

For shredding plastic, wood, construction waste. Critical for recycling operations and waste volume reduction.

🌾 Agriculture

For producing compound feeds, fertilizers. Ensures proper nutrition for livestock and optimal crop yields.

🍞 Food Industry

At bakeries, flour mills for grain grinding. Fundamental for producing flour, cereals, and other food ingredients.

⚗️ Chemical & Pharmaceutical

For grinding raw materials to required particle size. Ensures product consistency and quality in sensitive applications.

🏗️ Construction Materials

For grinding cement, gypsum, lime. Essential for producing building materials with specific properties.

In any of these industries, crusher or mill shutdown due to breakdown leads to serious financial losses, production delays, and potential contract penalties.

The Cost of Vibration: Hidden Threat to Your Production

Ignoring increased vibration is a direct path to emergency downtime. Rotor imbalance (the main cause of vibration) triggers destructive processes that compound over time, creating a cascade of failures throughout your equipment.

What does vibration lead to?

Bearing destruction: Constant vibrational loads lead to rapid wear and seizure of bearing units. Heat buildup accelerates degradation, potentially causing catastrophic failure without warning.

Fatigue cracks: Vibration transfers to the frame and foundation, causing cracks in metal structures and welds. These can propagate rapidly under continued stress, risking structural integrity.

Reduced product quality: Unstable equipment operation leads to uneven grinding or crushing, affecting the quality of the final product. This can result in customer complaints and loss of market share.

Increased wear: All adjacent units and assemblies experience increased load, reducing their service life. This creates a domino effect of maintenance issues throughout the production line.

The Economics of Industrial Downtime

The true cost of vibration-related failures extends far beyond immediate repair expenses:

Direct repair costs: The cost of replacing rotors, bearings, and foundation restoration can be colossal. Emergency repairs often cost 3-5 times more than preventive maintenance.

Indirect costs due to downtime: This is the most significant damage. Production line stoppage means lost profit, contract disruption, and penalty sanctions. In continuous process industries, losses can reach thousands of euros per hour.

Reputational risks: Unstable equipment operation undermines the trust of partners and customers. Reliability issues can lead to lost contracts and reduced market competitiveness.

Safety concerns: Excessive vibration increases the risk of catastrophic failure, potentially endangering personnel and leading to regulatory scrutiny.

Timely balancing is not an expense, but an investment in the stability and reliability of your production. Studies show that proper maintenance can extend equipment life by 50-200%.

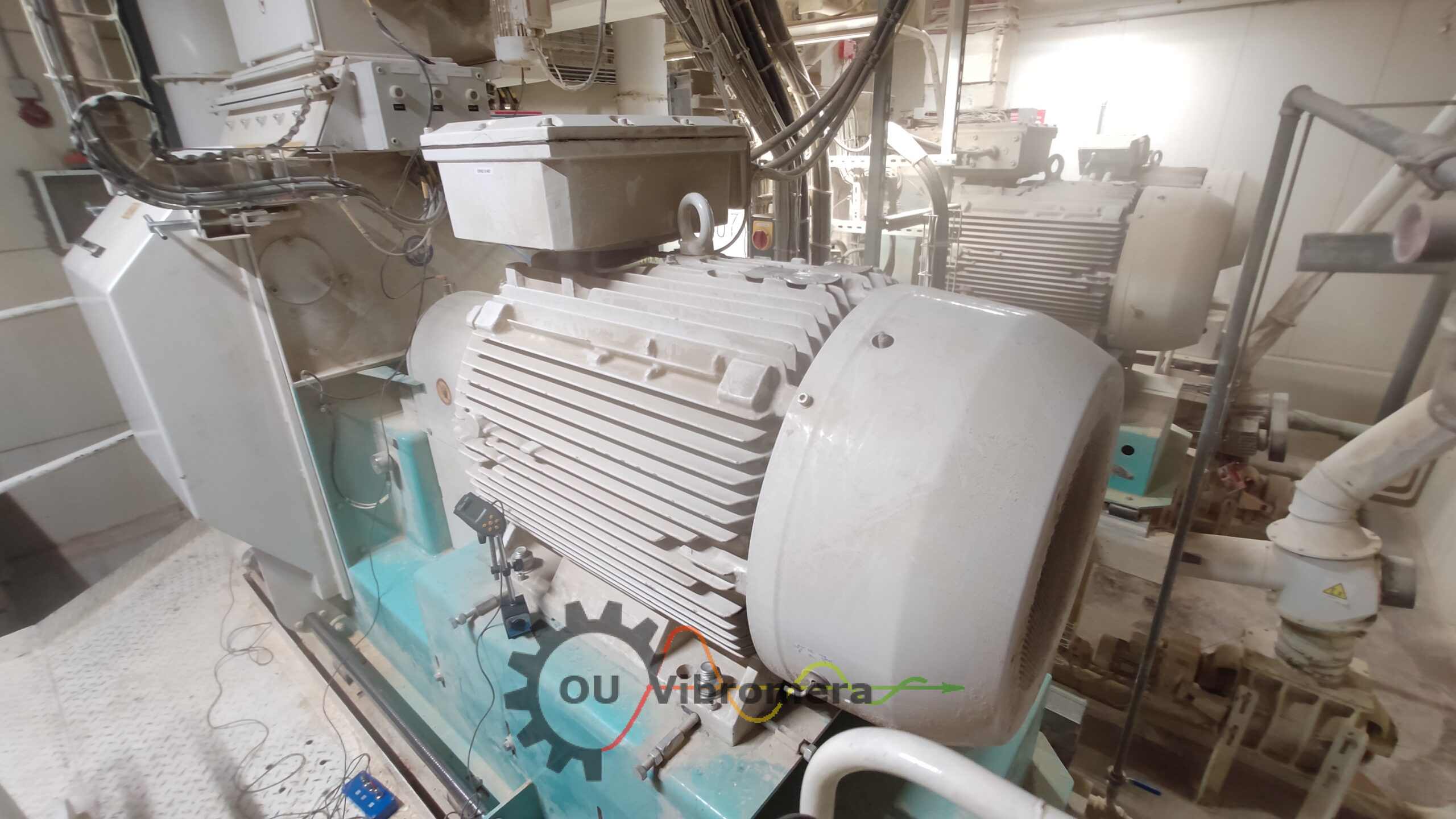

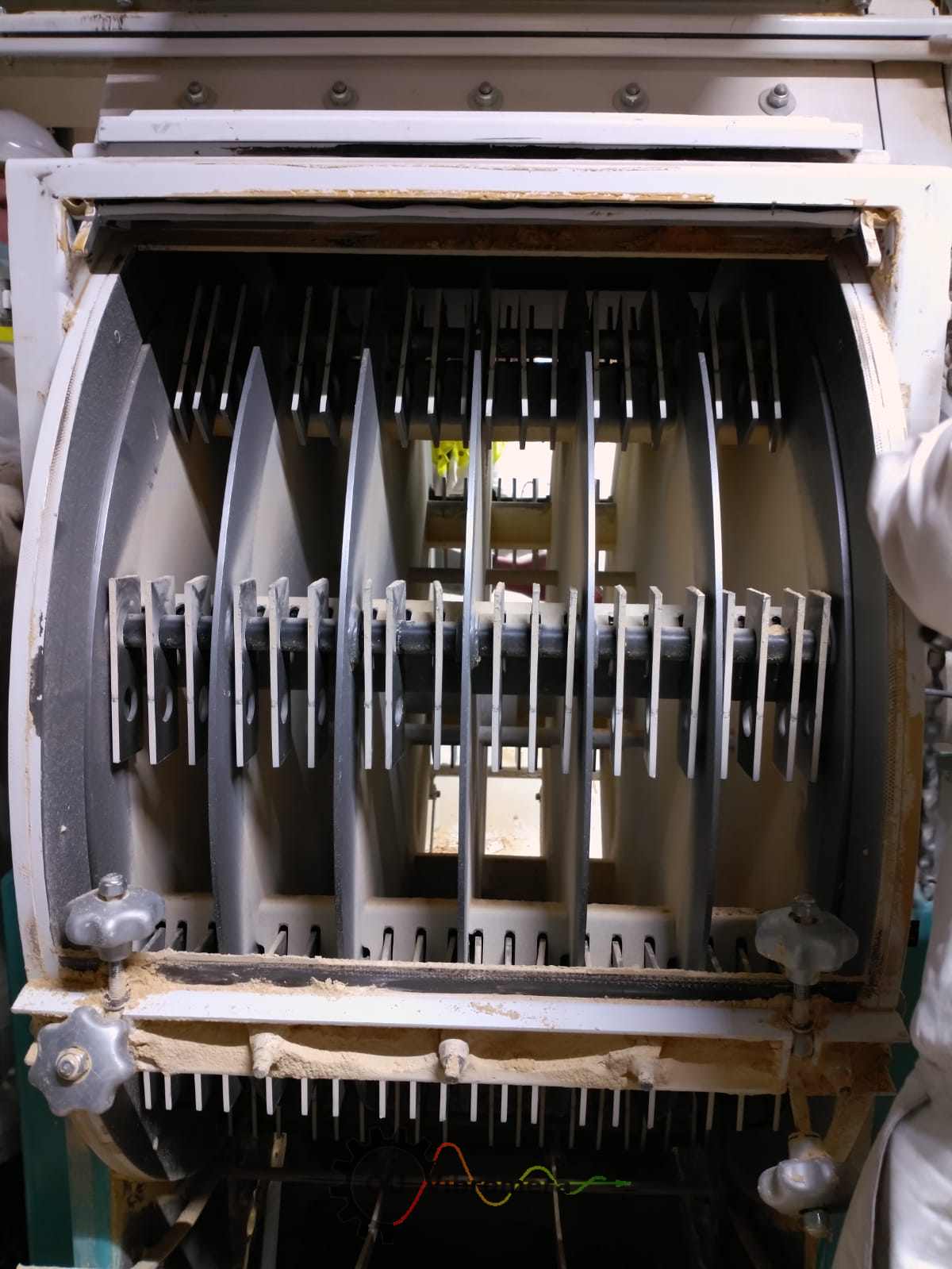

Our Work in Action: Crusher Balancing Gallery

Mobile Dynamic Balancing Throughout Europe 🇪🇺

Vibromera specializes in "in-situ" balancing (in own bearings). This method is the gold standard as it eliminates imbalance considering all factors: frame stiffness, bearing condition, and actual operating speeds.

How We Work

Engineer visit: Our specialist arrives at your facility anywhere in Europe with state-of-the-art diagnostic equipment and years of field experience.

Vibration diagnostics: Before starting work, we take measurements to accurately determine the cause of vibration. This comprehensive analysis includes frequency spectrum analysis and phase measurements.

Dynamic balancing: Using the Balanset-1A device, we balance the rotor in one or two planes, installing corrective weights in accordance with ISO 1940 standard. Our precision typically achieves G2.5 balance quality or better.

Work completion report: You receive an official document with "BEFORE" and "AFTER" vibration indicators — a guarantee of our service quality. This includes detailed measurements, corrective weight positions, and recommendations for future maintenance.

We work with all types of crushing and grinding equipment: hammer, jaw, cone, rotor crushers, as well as industrial mills. Our experience covers equipment from all major manufacturers including Metso, Sandvik, FLSmidth, and many others.

Terms and Pricing

We offer transparent and competitive pricing for our services, with no hidden costs or surprise charges.

Service Cost

depending on complexity and size

+ Transport expenses calculated individually

To carry out work, it is necessary to provide access to the equipment and the ability to run it at idle. We require standard industrial power supply and basic safety provisions. Our team is fully insured and certified for industrial site work.

Balanset-1A: Professional Balancing in Your Hands 🛠️

Vibromera strives to make professional technologies accessible. Our Balanset-1A device allows your engineers and mechanics to independently perform industrial-level balancing, reducing dependency on external services and minimizing equipment downtime.

The intuitive interface and step-by-step methodology make the process simple and effective, without requiring deep knowledge of vibration diagnostics. Even operators with basic technical skills can achieve professional results after minimal training.

Technical Specifications and Kit Contents

Balanset-1A is a portable two-channel device for balancing and vibration analysis, designed for harsh industrial environments.

- Number of channels: 2 (for simultaneous measurement)

- Vibration velocity measurement range: 0-80 mm/s RMS

- RPM measurement range: 250-90,000 rpm

- Phase measurement accuracy: ±1°

- Power supply: USB port of laptop (no external power needed)

- Operating temperature: -10°C to +50°C

- Protection class: IP65 (dust and water resistant)

Complete kit (price ~€1,751) includes:

- Balanset-1A interface unit with protective case

- Two high-sensitivity vibration sensors with magnetic mounts

- Laser optical tachometer with tripod mount

- Electronic scales for precise weight measurement

- Professional software with lifetime updates

- Comprehensive training materials and video tutorials

- All necessary accessories and carrying case

Functional Capabilities

Vibrometer mode: Vibration analysis, speed measurement, spectral analysis (FFT). Identify not just imbalance but also misalignment, looseness, and bearing defects.

Balancing mode: Single and two-plane balancing with polar diagram for visualization and built-in ISO 1940 tolerance calculator. The software guides you through each step with clear instructions and visual feedback.

Advanced features: Save and compare balancing sessions, generate professional reports, and track equipment condition over time with trend analysis.

We also offer demonstration and test drive of the device at your facility. See the Balanset-1A in action on your actual equipment before making a purchase decision.

Why Choose Vibromera?

Experience and expertise: For over 10 years we have been developing vibration diagnostic equipment trusted in more than 50 countries worldwide. Our team includes certified vibration analysts and mechanical engineers with decades of field experience.

Modern technology: We use our own developed equipment, which guarantees accuracy and reliability. Continuous R&D ensures our solutions stay at the forefront of balancing technology.

Comprehensive approach: We don't just eliminate vibration, but also provide recommendations on the overall condition of the equipment. Our reports include preventive maintenance suggestions to maximize equipment life.

Global coverage: We work throughout Europe, ensuring prompt on-site service. Our multilingual team can communicate effectively in English, Portuguese, Spanish, and other European languages.

Transparency and reputation: We value the trust of our customers and provide services at the highest level. Fixed pricing, detailed reports, and proven results have earned us long-term partnerships with industry leaders.

Training and support: We don't just sell equipment — we ensure your team can use it effectively. Comprehensive training, ongoing support, and regular webinars keep your skills current.

Don't Let Vibration Destroy Your Production

Timely balancing of crushers and mills is the key to stable and efficient operation of your equipment. Vibromera offers both professional on-site services and tools for solving this task independently.

Request Balancing Service Order Balanset-1AWhy Contact Us?

Free consultation • Technical assessment • Custom solutions • Immediate response for emergencies