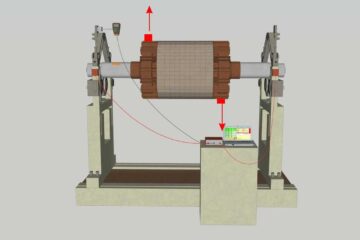

Fan Balancing

Fan Balancing (Information used from ISO 31350-2007 VIBRATION. INDUSTRIAL FANS. REQUIREMENTS FOR PRODUCED VIBRATION AND BALANCING QUALITY) Vibration produced by the fan is one of its most important technical characteristics. It indicates the quality of design and manufacture of the product. Increased vibration may indicate improper installation of the fan, deterioration of its technical condition, etc. For this reason, fan vibration is usually measured during acceptance tests, during installation before commissioning, as well as when performing a machine condition monitoring program. Fan vibration data is also used in the design of its support and connected systems (ducts). Vibration measurements are...

Read more