The Importance of Fan Balancing in Industrial Equipment Maintenance

Published by Nikolai Shelkovenko on

Fan Balancing – Eliminate Vibration & Extend Equipment Life

Imagine a high-speed industrial fan shaking violently, with bolts loosening at each rotation. This nightmare scenario is often caused by a slight imbalance in the fan's rotor. Excessive vibrations and noise are more than just nuisances — they are warning signs of a problem that can lead to costly downtime and repairs.

Fan balancing is the process of correcting this imbalance. It is one of the most sought-after procedures in equipment maintenance because fans are highly sensitive to any uneven weight distribution. Even the slightest deviation can lead to significant vibrations. An imbalance occurs when the geometric center of the fan's shaft doesn't align with its center of mass. The higher the fan's rotational speed, the more critical precise balancing becomes.

For example, an unbalance of just 20 grams at the edge of a large fan rotor spinning at 3000 RPM can generate about 900 N of centrifugal force — roughly like a 90 kg weight slamming on the bearings 50 times per second. It's no surprise that if left uncorrected, such imbalance quickly causes damage.

What Causes Fan Imbalance?

The most common causes of fan imbalance include:

- Abrasive wear on fan blades

- Dirt accumulation on fan blades

- Loose assembly or misalignment of the impeller on the hub

- Temperature fluctuations in the fan housing or shaft

- Loss of a balancing weight (previously added)

- Blade deformation (bending or damage)

Why Is Fan Balancing Important?

Operating an imbalanced fan results in vibrations that are hazardous to the overall structure. Excessive vibration leads to increased energy consumption, accelerated wear, and often premature failure of bearings (either on the shaft or in supporting structures). It can even cause unplanned downtime due to breakdowns.

On the other hand, a well-balanced fan will:

- Run more efficiently (less energy waste)

- Put less stress on its components

- Extend the lifespan of bearings and other parts

- Operate more quietly

In short, whether you are installing a new fan or servicing an existing one, you should never skip the balancing step during maintenance.

Important: While imbalance is the most common cause of high vibration in fans, it's not the only cause. Structural issues, excessive clearances, problems with belt drives, misalignments, cracks in the rotor, or faulty bearings can also create vibrations. It's crucial to have an experienced vibration diagnostic specialist determine the root cause of any increased vibration before assuming balancing will fix it.

Specialist's Comment

As experience shows, people often seek balancing services whenever there's an increase in vibration. However, balancing is actually the final step in reducing vibration. Before proceeding to that step, a thorough vibration diagnostic of the equipment's condition must be conducted. Any deficiencies – such as defects in couplings, lack of shaft alignment, or insufficient rigidity in the support structure – should be identified and corrected first. Only then should you proceed to the balancing stage, if it's still necessary.

For instance, a recent client requested fan balancing for a dryer unit. Our vibration measurements (specifically the vibration velocity spectrum) indicated the presence of mechanical looseness. Upon inspection, we discovered damage where the fan's support structure attached to the foundation. After re-securing the supports and re-diagnosing, we found the residual imbalance to be within acceptable limits. In this case, balancing was no longer needed. Issues like loose foundations or misalignments will prevent a successful balance. Remember, balancing should only be performed on a machine that is otherwise in sound mechanical condition.

How Fan Balancing Is Performed

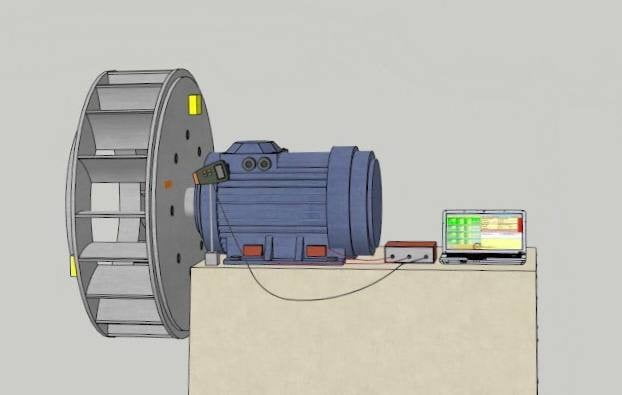

Our specialists typically perform fan balancing (either balancing the impeller or the whole fan wheel) on-site using the fan's own bearings. This in-situ approach allows for maximum precision and speed without requiring disassembly, avoiding unnecessary interference with the equipment's structure.

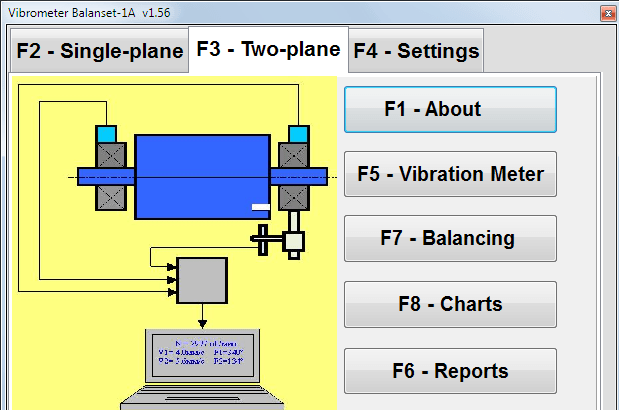

In every balancing job, we aim for the lowest possible residual imbalance and adhere to the balance quality standards of ISO 1940-1-2007 for the appropriate equipment class. To achieve this, we use a portable dynamic balancing device — the vibration analyzer Balanset-1A.

Steps Involved:

The balancing process consists of several stages. The number of sensors used and their placement may be specified by the fan manufacturer. General guidelines recommend placing sensors on the fan shaft bearings and on the housing. If this is not possible due to design constraints, then sensors should be mounted at locations as directly connected to the bearings as feasible.

- Install the vibration sensors perpendicular to the rotor's rotation axis.

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan's impeller. Balanset-1 Vibromera - Mount the tachometer on the magnetic stand.

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan's impeller. Balanset-1 Vibromera - Stick reflective tape on the pulley and point the RPM sensor toward the tape.

- Connect the vibration sensors to the balancing device, and connect the device to the laptop.

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan's impeller. Balanset-1 Vibromera - Start the balancing software on the laptop.

- Select the two-plane balancing mode.

Software for the Balanset-1A portable balancing instrument and vibration analyzer – Main Menu screen. - Enter the rotor identification (name or number) and its location.

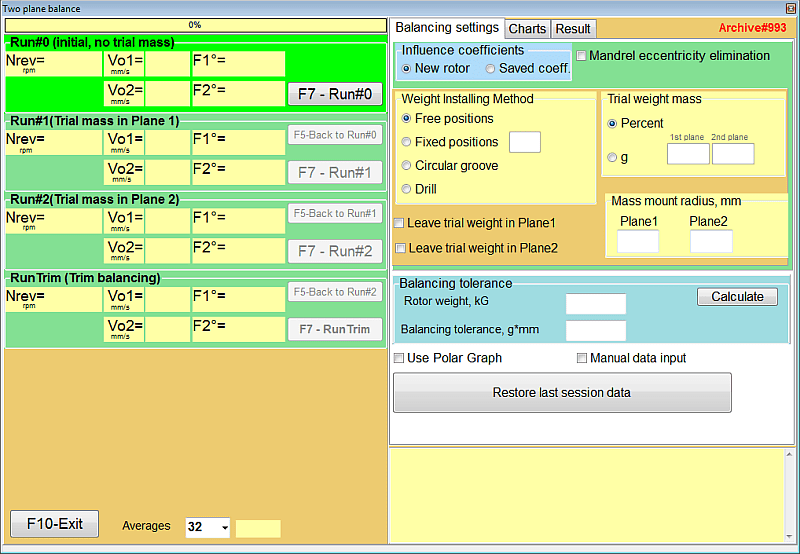

- Weigh the test weight and input its value and the radius at which it will be installed.

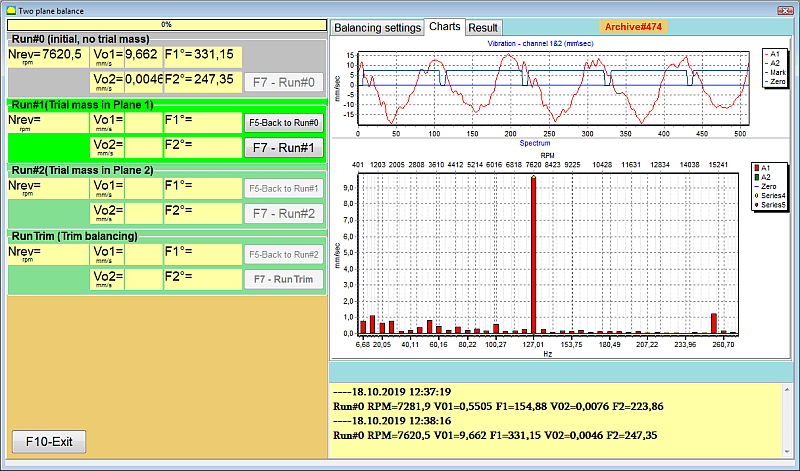

Software for the Balanset-1A portable balancing instrument and vibration analyzer – Setting up dynamic balancing parameters. - Run the fan (rotor) and measure the initial vibration level (baseline).

Software for the Balanset-1A portable balancer and vibration analyzer – Two-plane balancing window showing original (initial) vibration. - Install the test weight in the first correction plane on the fan's rotor.

- Run the fan again and take a second vibration measurement.

- Verify that the vibration amplitude or phase has changed by at least 20% (indicating the test weight had a measurable effect).

- Remove the test weight from the first plane and install it on the second plane of the rotor.

- Run the fan once more and take a third vibration measurement.

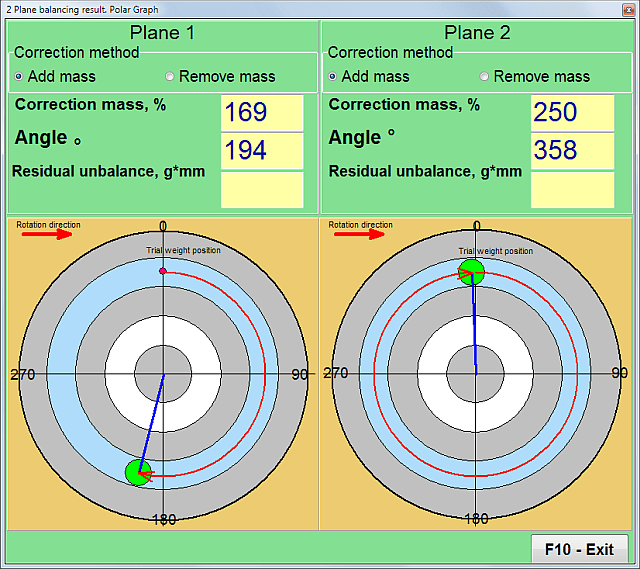

- The software then calculates the required correction weights and the angles at which to place them in the first and second planes.

Software for the Balanset-1A portable balancing instrument and vibration analyzer – Dual-plane balancing results (polar chart indicating where to add weights). - Remove the test weight from the rotor.

- Prepare the permanent correction weight of the specified mass (as calculated).

- Attach or weld the correction weight(s) onto the rotor at the indicated positions.

portable dynamic balancer, vibration analyzer "Balanset-1A" - Run the fan again and verify that the balancing was successful (vibration levels are now within acceptable limits).

- If the software suggests further minor adjustments, add the additional weight as recommended and recheck the balance until the vibration is minimized.

By following this procedure, we ensure a high level of precision in fan balancing, which contributes to the long-term efficiency and reliability of your industrial equipment.

Conclusion

Proper fan balancing eliminates one of the main sources of machinery vibration. The result is smoother and more reliable operation of your equipment. Neglecting this step can lead to costly failures, while implementing regular balancing (after fixing any underlying mechanical issues) will save you time and money in the long run. Don't wait for a fan to vibrate itself apart — include balancing as a routine part of your maintenance program to protect your machinery and keep it running optimally.

Frequently Asked Questions

What causes fan imbalance?

Fan imbalance is usually caused by an uneven distribution of mass in the rotating parts. Common causes include abrasive wear on fan blades, dirt buildup on blades, loose or misaligned impellers, temperature fluctuations that cause material expansion or contraction, loss of previously installed balance weights, or physical deformation of a blade.

Why is fan balancing important?

An imbalanced fan produces excessive vibration that can damage the fan and connected equipment. Balancing a fan reduces these vibrations, preventing energy waste and minimizing stress on bearings and other components. A properly balanced fan also operates more quietly and efficiently, extending the lifespan of the equipment.

How do you balance a fan?

Fan balancing is performed by adding or removing weight on the fan's rotor (impeller) to correct any mass imbalance. The general process involves measuring the fan's vibration, determining where the imbalance is, and then attaching small correction weights at specific positions on the rotor to counteract it. Modern portable balancers use sensors and software to guide this process and calculate the exact weight and placement needed. (See the step-by-step procedure above for details.)

When should an industrial fan be balanced?

An industrial fan should be balanced whenever you notice excessive vibration or after any repair/maintenance work that could disturb its balance (such as replacing or welding fan blades). New fans are typically well balanced by the manufacturer, but over time wear and material buildup can introduce imbalance. It's a good practice to periodically check vibration levels as part of maintenance, and perform balancing if those levels exceed the recommended limits.

Can fan balancing be done on-site?

Yes. Fan balancing can often be done on-site (in situ) using portable balancing equipment. In-place balancing, like the service described above, uses the fan's own bearings and does not require disassembling the machine. This saves time and ensures the fan is balanced under its normal operating conditions.