Balancing of Mill Rotors

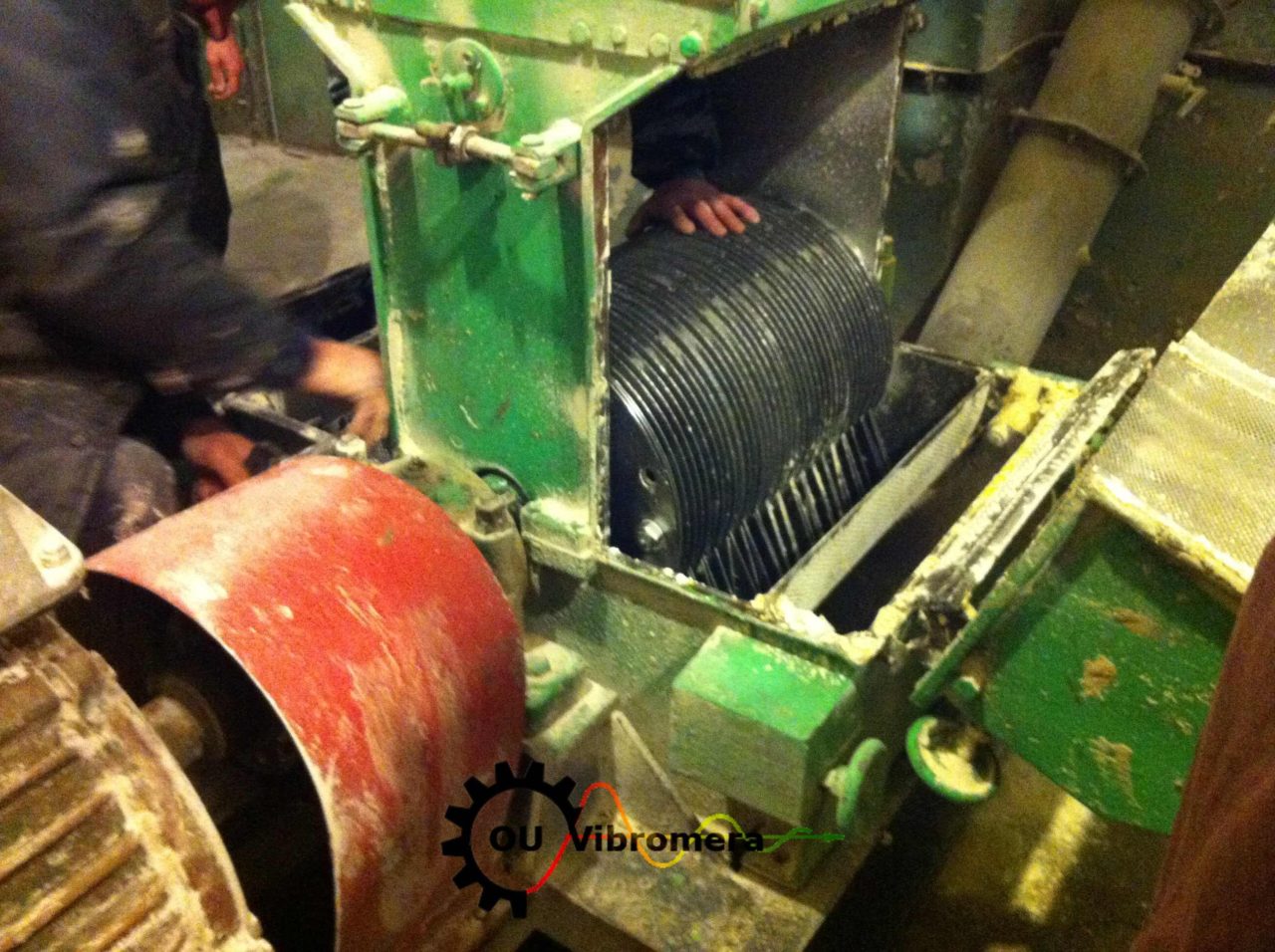

Something interesting: balancing the crusher.

Introduction:

Imbalance in mill rotors can result in accelerated bearing wear and increased energy consumption, both of which are undesirable for efficient milling operations.

Identified Issue:

Upon inspection, a pronounced axial vibration was observed in the mill rotors. Further investigation pinpointed the cause to be a misalignment of the semi-couplings.

Resolution:

To rectify the situation:

- Alignment: The misaligned semi-couplings were meticulously realigned to their correct positions.

- Balancing: Subsequent to the alignment, the rotors underwent a comprehensive balancing process to ensure smooth operation.

Outcome:

After the realignment and balancing procedures, the vibration issue was completely resolved, allowing the mill to operate at its optimal efficiency.

Conclusion:

The precise balancing and alignment of mill rotors are vital for their optimal functioning. Addressing misalignments and imbalances promptly ensures uninterrupted and efficient milling processes.