Portable multiplane balancer "Balanset-4"1. Introduction

|

2. Prepare to work. Software and hardware setup for multiplane balancing.2.1 Driver installation

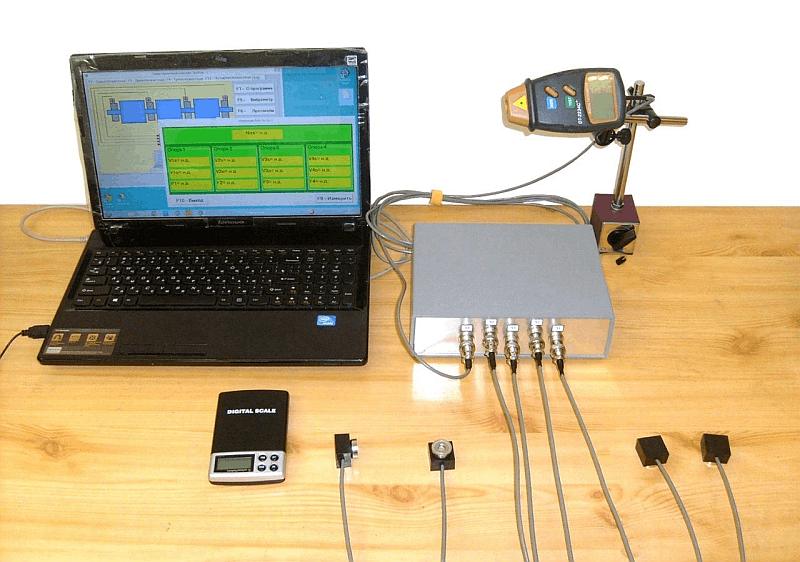

Install sensors as shown on the fig. 1,2 - vibration sensors to connectors X1,X2,X3,X4 - phase laser sensor to connector X5 |

Table 1 Multiplane balancing. Step-by-step guide

Run 0 - Start-up without test weight.

-

Run the machine at its operating speed (be sure that operating speed is far from resonance frequency of construction)

-

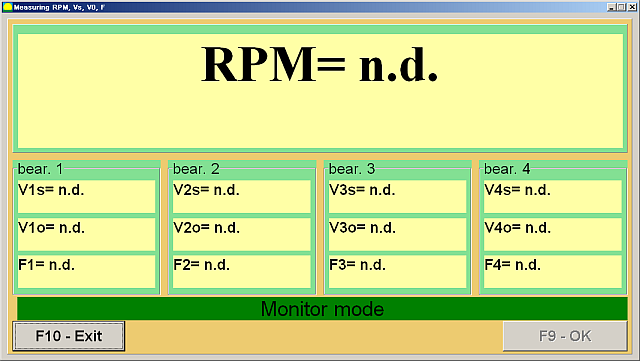

Click on F9-Start and measure the vibration level and phase angle in turn without test weight. Duration of the measuring process may amounts 2-10 sec.

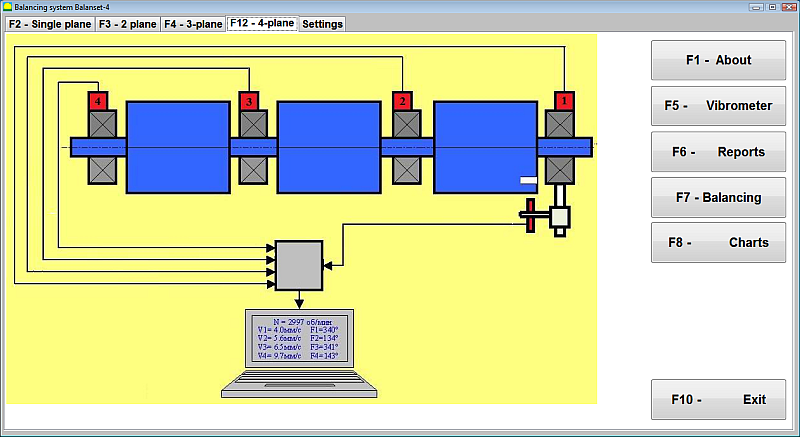

fig.3 Multiplane balancing window. Original vibration

|

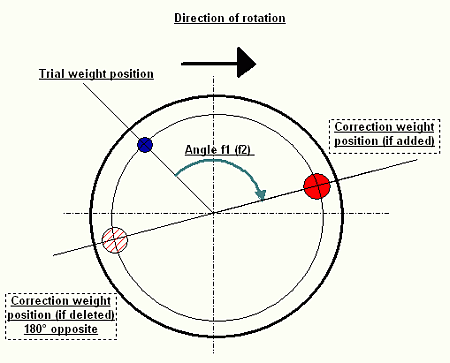

Run 1-4 - Test weight in plane 1-4

|

|

Step 4 - Calculation

|

|

RunC

|

4. Other features

4.1 Vibrometer mode.To select Vibrometer mode click "F5- Vibrometer" button in the main window for multiplane balancing (fig.1)

|

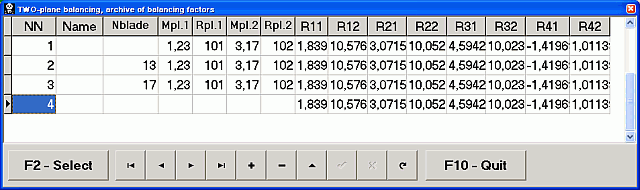

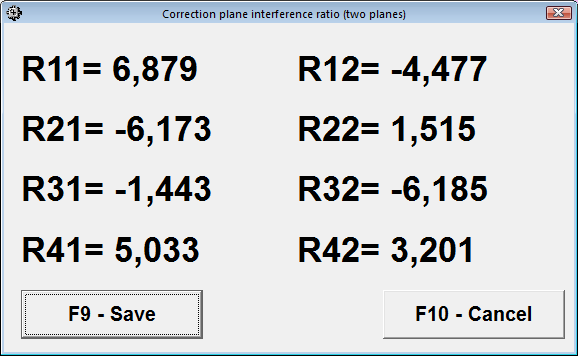

4.2 Influence balancing coefficientsIf you save the results of previous balance runs, you can eliminate the test weight run and balance the machine using its saved coefficients. Select "Secondary" in the "Type of balancing" window and click "F2 Select" button to choose previous machine type from list.

|

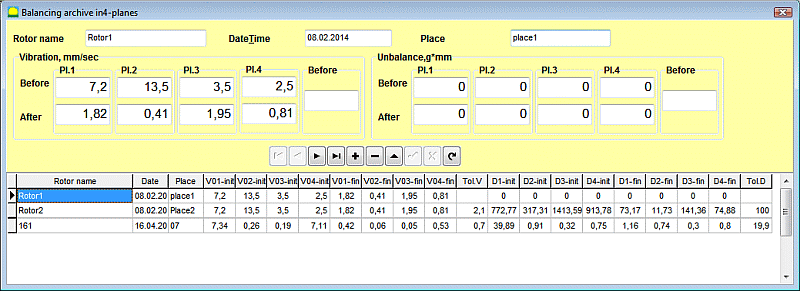

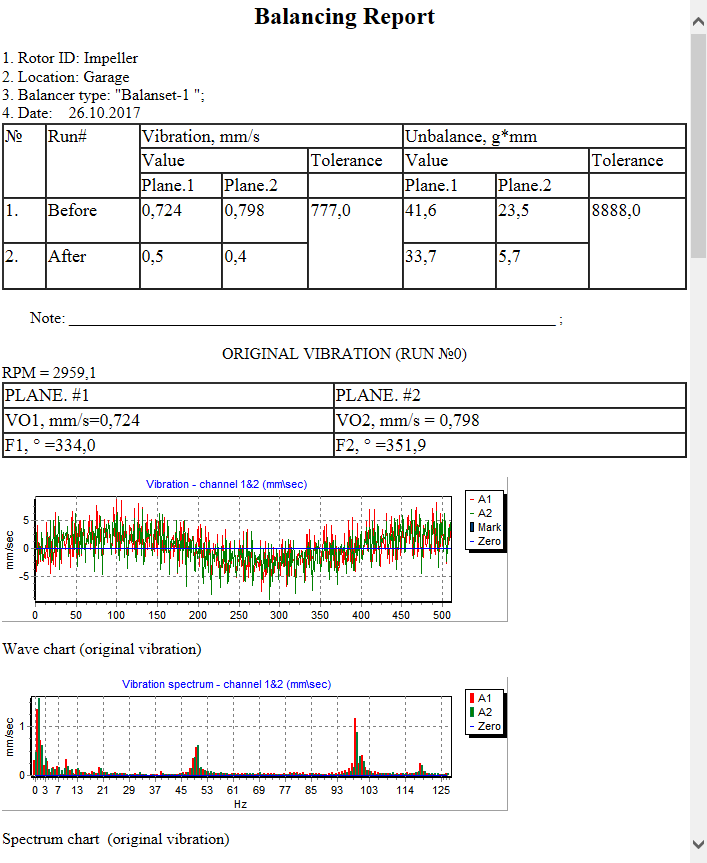

4.3 Rotor balancing frchives and reports.To save balancing information click "F9- Add to archive" in the balancing result pop-up window (see Tab.1). Input machine type ("Name") and other information in the table.

|

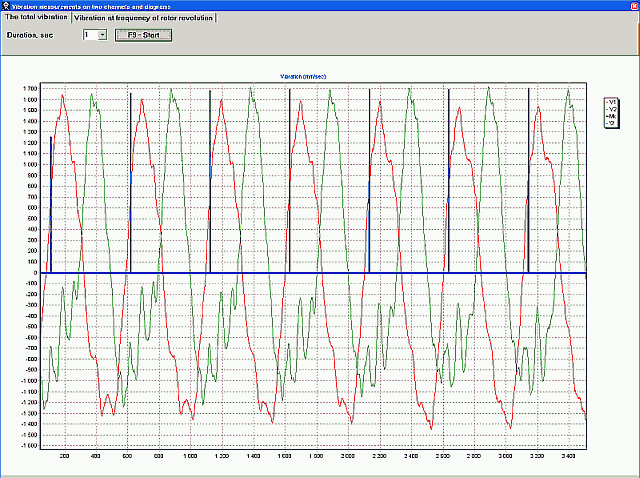

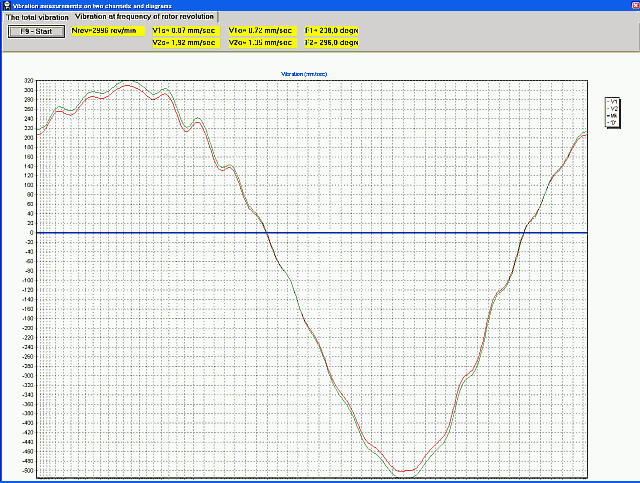

4.4 ChartsTo view charts of vibration click on "F8-Diagrams"Two kind of charts available "Total vibration" and "Vibration on rotor revolution frequency" (for example, for 3000 rev\min frequency is equal 50Hz) |

0 Comments