Is it possible? With determination – YES!

Balancing instruments rightfully occupy a special place among the wide range of equipment used for vibroacoustic measurements. This is largely due to the fact that this class of instruments, in addition to performing metrological functions, also fulfills a technological role. Essentially, it is technological equipment used to reduce the imbalance of rotary mechanisms.

As a result, it offers high economic efficiency, allowing for significant quality improvement of products with relatively small capital investments when implementing balancing equipment. This is especially true for industries where a significant amount of rotary equipment is operated or manufactured (e.g., milling enterprises, factories producing fans, etc.).

At such enterprises, the payback period for moderately priced balancing equipment, which ranges from 2500 to 10000 euros, typically does not exceed 6-7 months.

However, there are many small and medium-sized enterprises interested in balancing their own products, for which even these relatively small expenses are burdensome. These enterprises may include auto repair shops, electric motor repair and service facilities, pump and fan repair shops, etc. For them, purchasing balancing equipment at current market prices is often difficult, if not impossible.

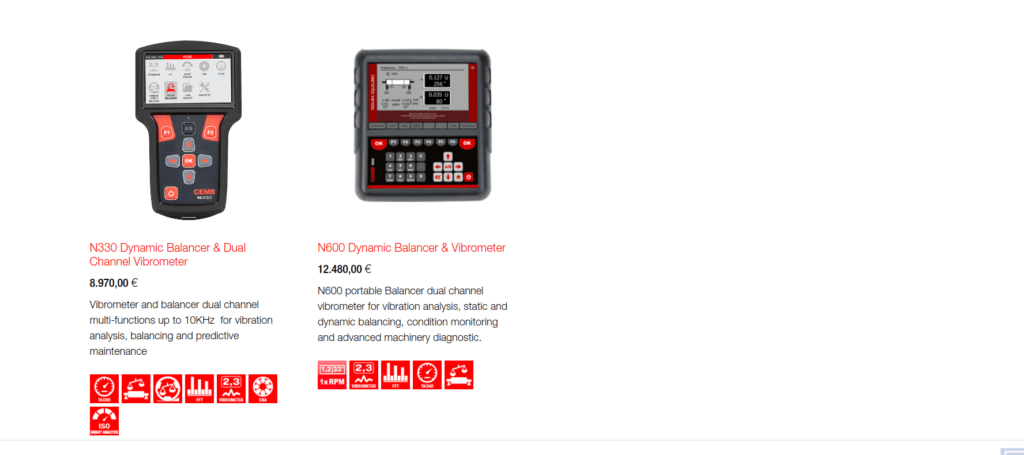

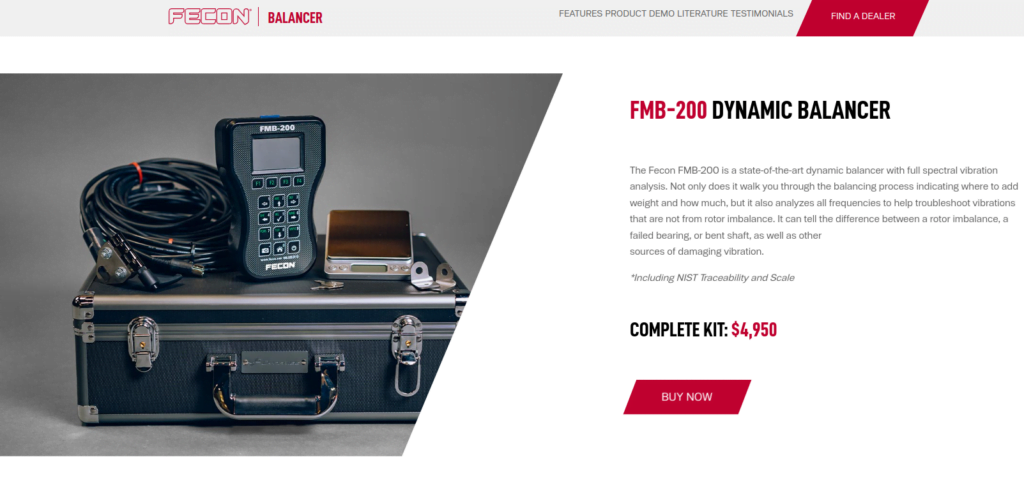

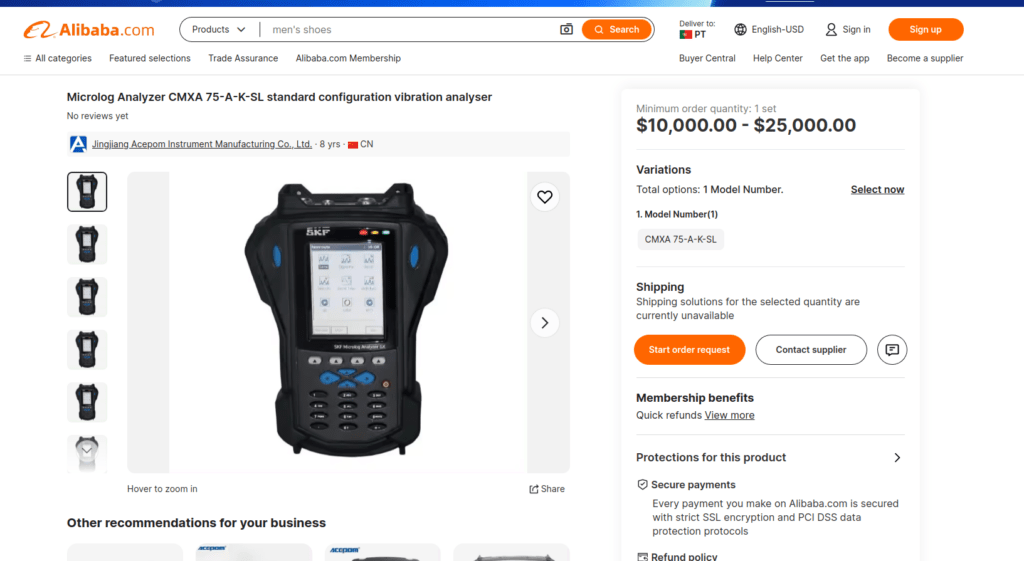

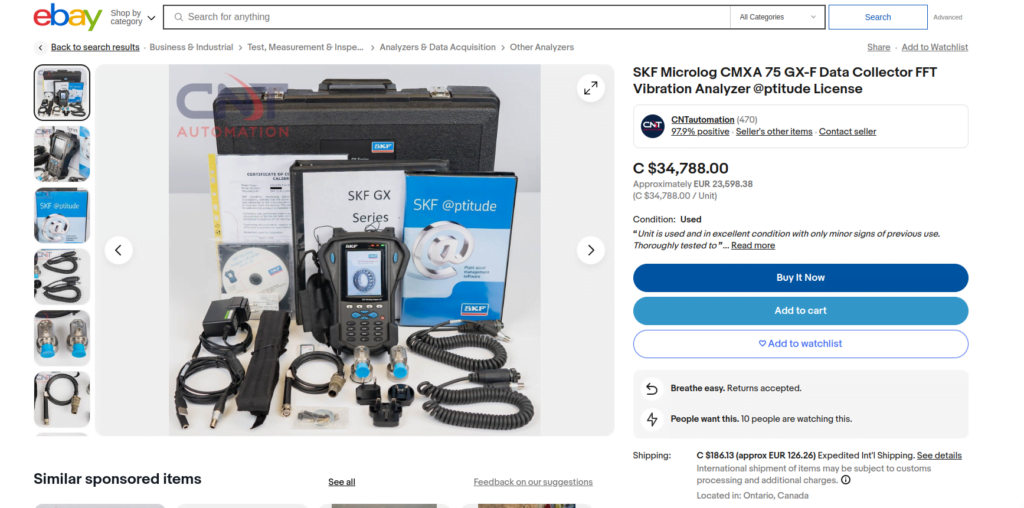

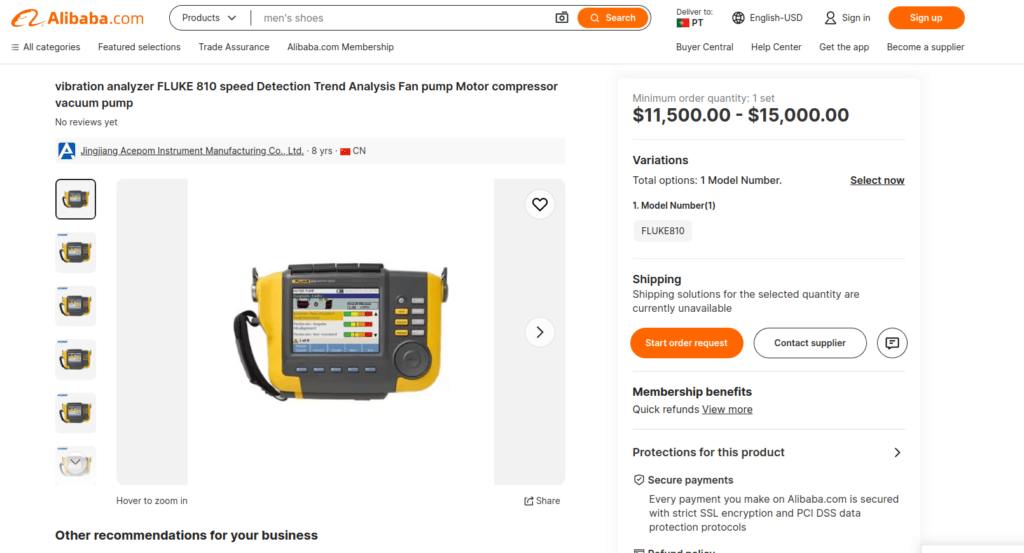

For reference, Table 1 provides information on some of the most well-known balancing instruments for rotary equipment currently on the market. As shown in the table, prices for these instruments can vary from 2500 to 25000 euros depending on the manufacturer and their functionality.

| Instrument | Price |

|---|---|

| Balancing machine VT-900 | $2,465.00 |

| FMB-100 Dynamic Balancer by FECON | $2,750 |

| Beacon LC-830A Portable On-site Analyze Vibration Dynamic Balancing Machine | $2,800.00 |

| Adash A4300 VA3 Pro Ex Vibration Analyzer | $4,270.00 |

| FMB-200 Dynamic Balancer by FECON | $4,950 |

| ACEPOM322 Vibration Analyzer and Field Dynamic Balancer | $4,500.00 |

| Adash A4500 VA5 Pro Vibration Analyzer – Thermal Imaging – Ultrasound | $6,200.00 |

| Vibration Analyzer AX-F CMXA 80-F-K-SL by Acepom | $6,500.00 |

| HG904 Hot Sale Double Channels Portable Vibration Analyzer Dynamic Balancer Testing Machine | $7,150.00 |

| Field Balancing Machine | $8,500.00 – $12,000.00 per Piece |

| Zero Dynamic Field Balancing and Vibration Analysis Instrument | $8,500.00 – $12,000.00 per Piece |

| N330 Dynamic Balancer & Dual Channel Vibrometer | €8,970.00 |

| N600 Dynamic Balancer & Vibrometer | €12,480.00 |

| Fluke 810 Vibration Tester | $13,625.99 |

| Microlog Analyzer CMXA80-F-K-SL-ND Vibration Analyzer by SKF | $14,178.00 – $15,000.00 |

| SKF Microlog Analyzer CMXA 75-A-K-SL Standard Configuration | $10,000.00 – $25,000.00 |

| SKF Microlog CMXA 75 GX-F Data Collector FFT Vibration Analyzer | $34,788.00 |

| VIBXPERT II by Prüftechnik | $21,645 – $52,230 |

table 1. Prices are taken from public sources: manufacturers’ websites, ebay, alibaba.com, etc.

At first glance, in the age of rapid development of modern electronics, these prices may seem excessively high. However, several objective factors limit the possibility of minimizing the cost of balancing instruments and vibrometers.

Firstly, balancing equipment is not in demand in volumes comparable to the production of computers, mobile phones, or televisions. It is usually produced in small and medium batches, which naturally affects its cost.

Secondly, the price of this equipment is significantly influenced by the cost of at least two vibration sensors included in its composition, which are quite expensive. For example, the cost of well-known sensors averages between 300 and 900 euros each.

Thirdly, significant expenses are directed towards the development of specialized software for balancing instruments, which, given the relatively small production volumes, also contributes to the increase in its cost.

However, there are reserves to reduce the cost of balancing equipment, and we have tried to use them in the development of our new instrument, named “Balanset-1A”.

We followed these guidelines:

- Attempt to implement a structural scheme of the instrument that maximally uses mass-produced components from other manufacturers.

- Explore the option of using cheaper vibration sensors to reduce the cost of our equipment.

- Maximally utilize balancing instrument management algorithms developed by our specialists over the past 20 years and successfully implemented in previous designs.

As a result of implementing the principles outlined above, the “Balanset-1A” balancing set was developed, consisting of the following main units:

- A microprocessor measurement unit with a USB output for connection to a computer.

- A portable computer equipped with specialized software for solving balancing tasks.

- Two relatively inexpensive vibration sensors.

- A laser phase angle sensor.

The measurement unit of the instrument was developed based on the serially produced Atmel SAM3X8E ARM Cortex-M3 CPU. The measurement unit is connected to a computer (usually a netbook or laptop) via a USB channel, through which the balancing process is managed and the measurement and calculation results are displayed.

Implementing this structure of the balancing instrument, based on the use of serially produced components, allowed us to significantly reduce the development and manufacturing costs of its hardware part.

An equally important element in reducing the cost of our product was the use of capacitive accelerometers as vibration sensors, which are currently mass-produced by various manufacturers and have a low cost.

Additionally, as mentioned earlier, the software development for the new balancing instrument extensively utilized algorithms developed by our specialists over the past 20 years. This significantly reduced the labor intensity of software development and debugging, positively affecting the equipment’s cost.

The comprehensive result of our work is that the cost of our proposed balancing set (without a computer) with all necessary accessories (including magnets for mounting vibration sensors, a magnetic stand for the phase angle sensor, a flash drive with software, and a transport case) does not exceed 2000 euros (1500 for the Balanset-oem set) at present.

In conclusion, we can state that our proposed “Balanset” balancing set is often significantly cheaper than the available equipment of similar purpose (see Table 1). In practice, its price is often comparable to the cost of regular vibrometers currently available on the market.

0 Comments