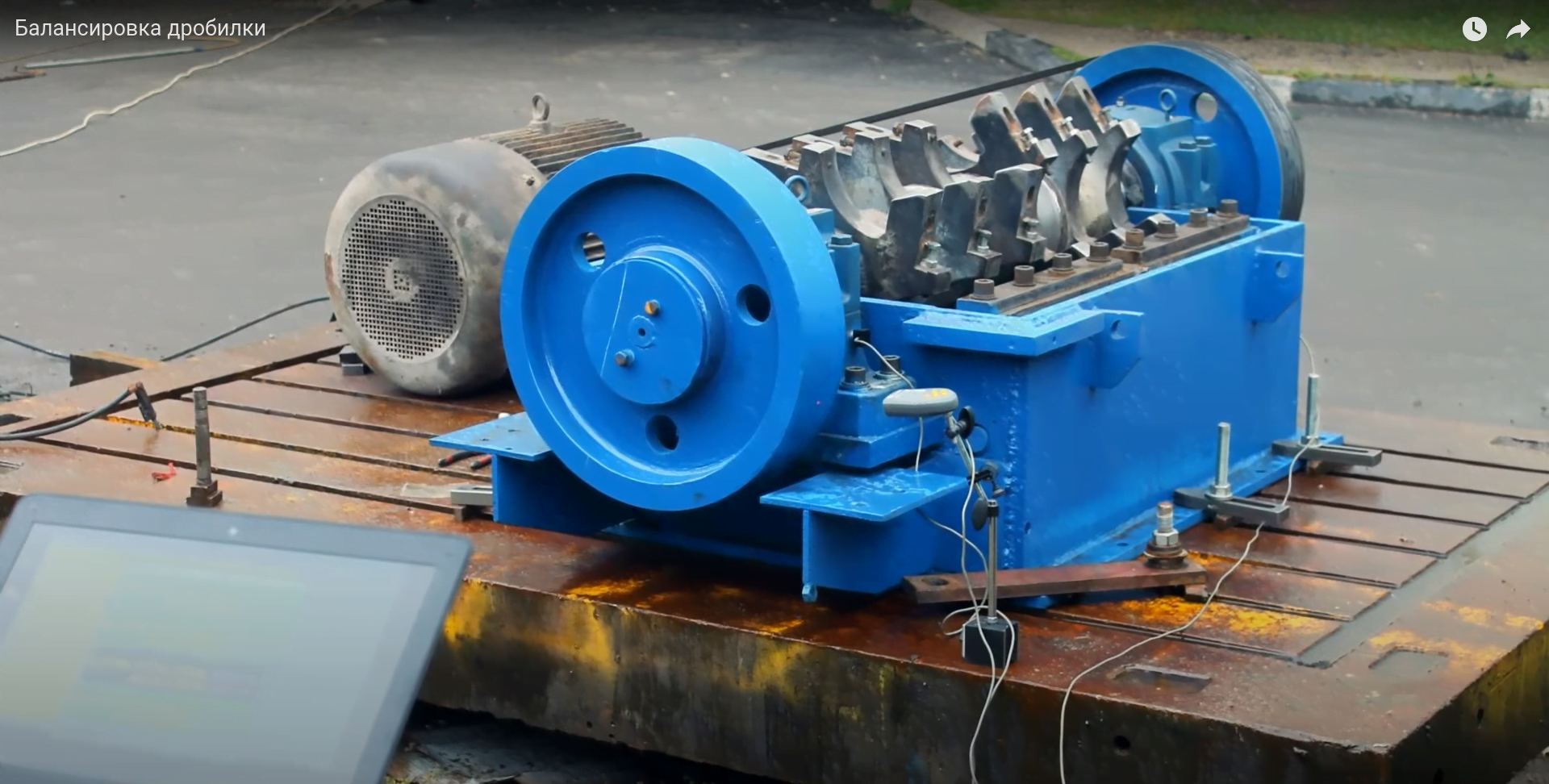

Rotor Balancing in Crusher Machines

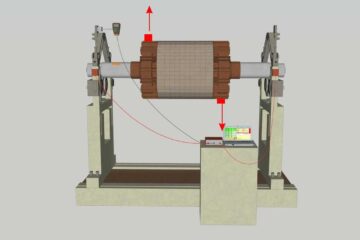

Crusher and Mill Balancing – Complete Guide | Balanset-1A 🔧 Complete Guide to Crusher and Mill Balancing From Theory to Practice: Save up to 50% on Repairs, Extend Equipment Life by 3x 💡 Did You Know? An imbalance of just 100 grams on a crusher rotor creates an impact force equivalent to 50 hammer blows per second on your bearings! Balancing the crusher using the Balanset-1A vibration analyzer 🎯 Why Is Balancing Critically Important? 💰 Cost Savings Reduce repair costs by up to 50% and extend maintenance intervals by 3-5 times ⚡ Energy Efficiency Reduce energy consumption by 5-15% by Read more