Products

-

Portable balancer & Vibration analyzer Balanset-1A

$2,390.24

Portable balancer & Vibration analyzer Balanset-1A

$2,390.24

-

Dynamic balancer “Balanset-1A” OEM

$2,099.78

Dynamic balancer “Balanset-1A” OEM

$2,099.78

-

Vibration sensor

$108.92

Vibration sensor

$108.92

-

Optical Sensor (Laser Tachometer)

$150.07

Optical Sensor (Laser Tachometer)

$150.07

-

Balanset-4

$8,233.33

Balanset-4

$8,233.33

Hydraulic Pump Balancing with the Balanset-1A Device

A practical guide for maintenance engineers and technicians, covering dynamic balancing technology using the portable Balanset-1A device

1. Purpose and Operating Principle

Hydraulic pump balancing is a procedure for eliminating imbalance of rotating parts to reduce vibration and increase equipment service life.

The balancing process involves measuring the rotor’s vibration and phase, then adding or removing small correction weights on the impeller or shaft. By counteracting the uneven mass distribution, this procedure significantly reduces the centrifugal forces that cause vibration and potential damage.

Main causes of imbalance:

- Manufacturing inaccuracies of impeller and shaft

- Wear and damage during operation

- Corrosion and cavitation damage

- Incorrect assembly after repair

Consequences of imbalance:

- Increased vibration and noise

- Accelerated wear of bearings and seals

- Reduced pump efficiency

- Risk of emergency failure

2. Technical Description of Balanset-1A

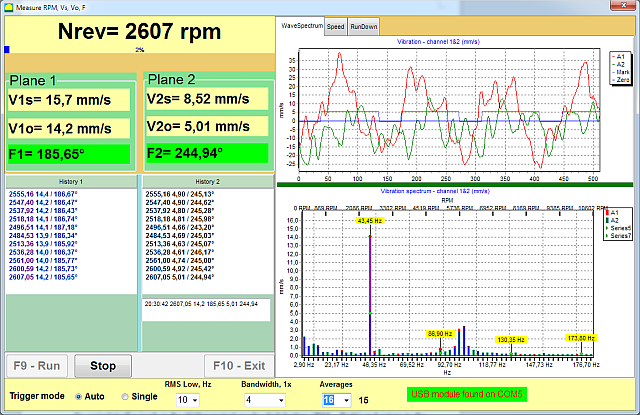

Balanset-1A is a portable dual-channel device for dynamic balancing of rotors directly at the workplace (in-situ).

Balanset-1A System Structure

Technical specifications

| Parameter | Value | Unit |

|---|---|---|

| Vibration velocity measurement range (RMS) | 0.02 - 80 | mm/s |

| Frequency range | 5 - 550 | Hz |

| Rotational speed measurement range | 100 - 100,000 | rpm |

| Phase measurement accuracy | ±1 | degree |

| Number of correction planes | 1 or 2 | - |

| Operating temperature | +5...+50 | °C |

Device package contents

USB interface with preamplifiers and ADC

2 accelerometers with magnetic mounting

Phase sensor with magnetic stand

For installation on pump shaft

For precise weight measurement

On USB drive with instructions

3. Preparation for Balancing

Sensor installation

Sensor installation diagram on hydraulic pump

- Install vibration sensors on the pump housing near the bearings, oriented perpendicular to the shaft axis

- Attach reflective tape on the pump shaft or coupling

- Mount the laser tachometer on a magnetic stand opposite the reflective tape

- Connect the sensors to the measuring unit

- Connect the measuring unit to the laptop via USB

4. Balancing Procedure

The balancing procedure with Balanset-1A typically follows a three-run method (influence coefficient method) using trial weights. Below is a step-by-step outline of the process, from measuring initial vibration to installing correction weights and verifying the results.

Initial vibration measurement

- Start Balanset-1A software

- Select single-plane or two-plane balancing mode

- Start the pump at operating speed

- Press "Run#0" in the software to measure initial vibration

- Record the vibration amplitude and phase values

Trial weight installation

- Stop the pump

- Weigh a suitable trial weight using the electronic scales

- Install the weight on the rotor in the first correction plane

- Enter the weight’s mass and installation radius into the software

- Restart the pump and perform the "Run#1" measurement

Second plane measurement (for two-plane balancing)

- Stop the pump and remove the trial weight from the first plane

- Attach the trial weight to the second correction plane

- Start the pump and perform the "Run#2" measurement

- The software will automatically calculate the required correction weights

Correction weight installation

- Stop the pump and remove any trial weights

- Manufacture or select the correction weights as per the software’s calculation

- Secure the weights by welding, bolting, or using clamps

- The installation angle for each weight is measured from the trial weight position in the direction of rotation

Verification measurement

- Run the pump at operating speed

- Perform a control measurement ("RunTrim")

- Verify that vibration has been reduced to acceptable levels

- Adjust weight masses and repeat measurement if necessary

5. Balancing Quality Assessment Criteria

Acceptable residual vibration values

| Pump type | Acceptable vibration, mm/s | Note |

|---|---|---|

| Centrifugal pumps up to 15 kW | ≤ 2.8 | Good condition |

| Centrifugal pumps 15–75 kW | ≤ 4.5 | Good condition |

| Centrifugal pumps over 75 kW | ≤ 7.1 | Good condition |

| Any pumps | > 11.2 | Unacceptable |

Signs of successful balancing

- 70–90% reduction in vibration at the 1× rotational frequency

- Stable and consistent vibration phase readings

- Absence of unusual noise

- Smooth, uniform pump operation

6. Practical Recommendations

Balancing frequency

Scheduled balancing

- New equipment – after initial run-in period

- After major repairs – mandatory

- Annually for critical equipment

- When vibration levels double from baseline

Unscheduled balancing

- Upon noticing unusual vibration or noise

- After any impeller replacement

- If vibration exceeds acceptable levels

- After an emergency shutdown

Requirements for quality balancing

- Ensure the pump is in good mechanical condition

- Verify the pump is firmly mounted on a stable foundation

- Check that bearings have no excessive play

- Confirm proper alignment between pump and driver

- Maintain stable operating speed during balancing

Results documentation

- Keep a log of all balancing work performed

- Save the Balanset-1A software reports for each balance job

- Document the mass and position of installed correction weights

- Record the final vibration levels after balancing (control measurements)

Conclusion

The portable Balanset-1A device provides effective balancing of hydraulic pumps directly at the workplace. Proper application of this technology allows users to:

- Reduce equipment vibration by a factor of 3–10

- Increase bearing service life by 2–5 times

- Lower energy consumption by 5–15%

- Prevent emergency breakdowns

- Decrease overall maintenance costs

Regular balancing of hydraulic pumps is an important part of the planned preventive maintenance system for industrial equipment.

Frequently Asked Questions (FAQ)

What is hydraulic pump balancing?

Hydraulic pump balancing is the process of correcting the uneven distribution of mass in a pump’s rotating components (such as the impeller and shaft). By adding or removing small weights, the goal is to eliminate excessive vibration and noise, improving performance and extending the pump’s service life.

Why is balancing a hydraulic pump important?

Balancing a pump is crucial because an imbalanced pump can cause excessive vibration and noise, leading to accelerated wear of bearings and seals, reduced efficiency, and an increased risk of sudden failure. Proper balancing helps ensure smooth, efficient, and reliable pump operation.

How do you balance a hydraulic pump?

Hydraulic pump balancing is typically done by using a device like the Balanset-1A. The process involves measuring the pump’s vibration and phase, adding a trial weight to the rotor, measuring the change, and then calculating and installing a correction weight at a specific location. After installing the correction weight, the pump is run again to verify that vibration levels have dropped to acceptable limits.

What equipment is used for pump balancing?

Pump balancing requires a vibration measurement and balancing system. The Balanset-1A kit, for example, includes a USB interface module, two vibration sensors (accelerometers), a laser tachometer (phase reference sensor), reflective tape for the rotor, electronic scales for weighing trial and correction weights, and specialized software running on a laptop to guide the balancing procedure.

How often should a pump be balanced?

Pumps should be balanced whenever there is significant vibration or after events that could cause imbalance. It’s recommended to balance new pumps after an initial run-in period, after major repairs or impeller replacements, and as part of annual maintenance for critical pumps. Unscheduled balancing is advised if unusual vibration or noise appears or after any emergency shutdown.

What are acceptable vibration levels for a balanced pump?

Acceptable vibration levels depend on pump size and power. For example, small centrifugal pumps (up to 15 kW) should typically have vibration ≤ 2.8 mm/s (RMS) when well balanced. Medium pumps (15–75 kW) should be ≤ 4.5 mm/s, and large pumps (>75 kW) ≤ 7.1 mm/s. Any pump with vibration above about 11.2 mm/s is generally considered to have an unacceptable imbalance and needs attention.

Does balancing fix all vibration issues?

No. Balancing addresses vibration caused by rotor mass imbalance. It will significantly reduce vibrations at the rotational frequency, but it cannot fix other sources of vibration such as misalignment, worn bearings, bent shafts, or other mechanical problems. Those issues must be diagnosed and repaired separately.