Assembled separator balancing

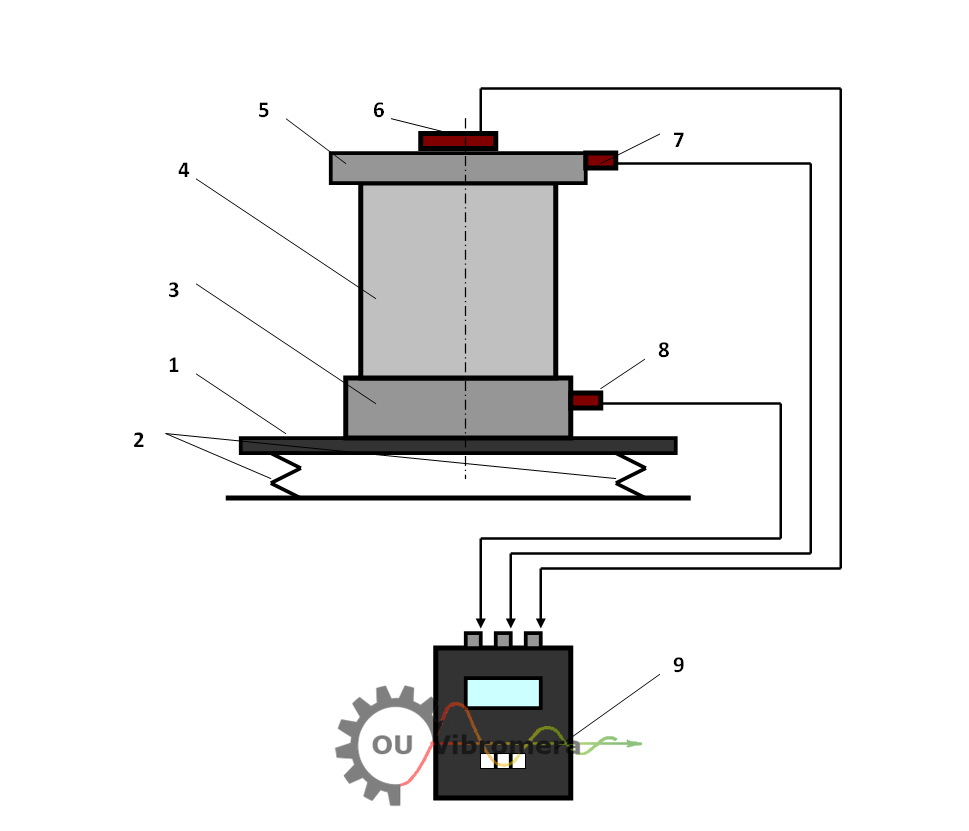

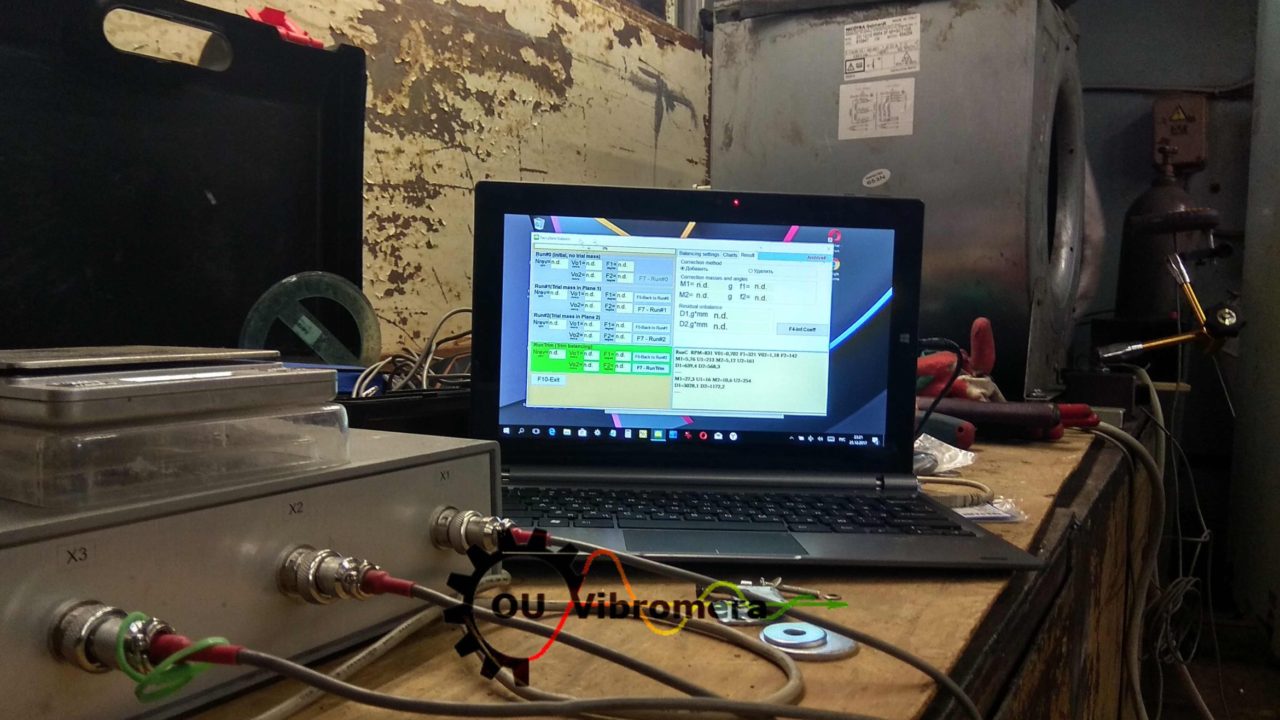

Traditional Balancing Limitations Previously, separator manufacturing plants used technology that required individual components of the separator to be balanced on specialized balancing machines. This posed challenges in achieving acceptable vibration levels for the assembled machines. Due to the high rotation frequencies of separator rotors, even slight manufacturing and assembly errors could lead to elevated imbalance levels. Transition to Assembled Balancing Our team introduced a new balancing device that enabled the final balancing of assembled separators at their operating rotation frequency. This transition opened up the possibility of maintaining residual vibrations within the range of 0.5 – 0.7 mm/s at rotation Read more