Portable balancer & Vibration analyzer Balanset-1A

$2,391.87

The Balanset-1A is equipped with 2 channels and is designed for dynamic balancing in two planes. This makes it suitable for a wide range of applications, including crushers, fans, mulchers, augers on combines, shafts, centrifuges, turbines, and many others. Its versatility Read more

Fan Balancing

(Information used from ISO 31350-2007 VIBRATION. INDUSTRIAL FANS. REQUIREMENTS FOR PRODUCED VIBRATION AND BALANCING QUALITY)

Vibration produced by the fan is one of its most important technical characteristics. It indicates the quality of design and manufacture of the product. Increased vibration may indicate improper installation of the fan, deterioration of its technical condition, etc. For this reason, fan vibration is usually measured during acceptance tests, during installation before commissioning, as well as when performing a machine condition monitoring program. Fan vibration data is also used in the design of its support and connected systems (ducts). Vibration measurements are usually performed with open suction and discharge ports, but it should be noted that fan vibration can vary significantly with changes in airflow aerodynamics, rotational speed, and other characteristics.

ISO 10816-1-97, ISO 10816-3-2002, and ISO 31351-2007 establish measurement methods and define vibration sensor locations. If vibration measurements are carried out to assess their impact on the duct or fan base, the measurement points are chosen accordingly.

Fan vibration measurements can be expensive, and sometimes their cost significantly exceeds the cost of manufacturing the product itself. Therefore, any restrictions on the values of individual discrete vibration components or vibration parameters in frequency bands should only be introduced when exceeding these values indicates a fan malfunction. The number of vibration measurement points should also be limited based on the intended use of the measurement results. Usually, it is sufficient to measure vibration at the fan supports to assess the fan’s vibrational state.

The base is what the fan is mounted on and what provides the necessary support for the fan. The mass and stiffness of the base are chosen to prevent the amplification of the vibration transmitted through it.

Supports are of two types:

- compliant support: A fan support system designed so that the first natural frequency of the support is significantly lower than the operating rotational frequency of the fan. When determining the degree of compliance of the support, elastic inserts between the fan and the support structure should be considered. The support’s compliance is ensured by suspending the fan on springs or placing the support on elastic elements (springs, rubber isolators, etc.). The natural frequency of the suspension system – fan is usually less than 25% of the frequency corresponding to the minimum rotational speed of the tested fan.

- rigid support: A fan support system designed so that the first natural frequency of the support is significantly higher than the operating rotational frequency. The stiffness of the fan base is relative. It should be considered in comparison with the stiffness of the machine bearings. The ratio of the bearing housing vibration to the base vibration characterizes the influence of the base’s compliance. The base can be considered rigid and sufficiently massive if the amplitude of the base vibration (in any direction) near the machine’s feet or support frame is less than 25% of the maximum vibration measurement result obtained at the nearest bearing support (in any direction).

Since the mass and stiffness of the temporary base on which the fan is installed during factory testing may differ significantly from the installation conditions at the operating site, the factory conditions’ limit values apply to narrow-band vibration in the rotational frequency range, and for on-site fan testing – to broadband vibration, determining the overall vibrational state of the machine. The operating site is the final installation location of the fan, for which the operating conditions are defined.

Fan Categories (BV-categories)

Fans are categorized based on the characteristics of their intended use, balancing accuracy classes, and recommended vibration parameter limit values. The design and purpose of the fan are criteria that allow classifying many types of fans according to acceptable imbalance values and vibration levels (BV-categories).

Table 1 presents the categories to which fans can be attributed based on their application conditions, considering permissible imbalance values and vibration levels. The fan category is determined by the manufacturer.

Table 1 – Fan Categories

| Application Conditions | Examples | Power Consumption, kW | BV-category |

| Residential and Office Spaces | Ceiling and Attic Fans, Window Air Conditioners | ≤ 0.15 | BV-1 |

| > 0.15 | BV-2 | ||

| Buildings and Agricultural Premises | Fans for Ventilation and Air Conditioning Systems; Fans in Series Equipment | ≤ 3.7 | BV-2 |

| > 3.7 | BV-3 | ||

| Industrial Processes and Power Generation | Fans in Enclosed Spaces, Mines, Conveyors, Boilers, Wind Tunnels, Gas Cleaning Systems | ≤ 300 | BV-3 |

| > 300 | see ISO 10816-3 | ||

| Transport, including Marine Vessels | Fans on Locomotives, Trucks, and Cars | ≤ 15 | BV-3 |

| > 15 | BV-4 | ||

| Tunnels | Fans for Ventilating Subways, Tunnels, Garages | ≤ 75 | BV-3 |

| > 75 | BV-4 | ||

| Any | BV-4 | ||

| Petrochemical Production | Fans for Removing Hazardous Gases, and Used in Other Technological Processes | ≤ 37 | BV-3 |

| > 37 | BV-4 | ||

| Computer Chip Production | Fans for Creating Clean Rooms | Any | BV-5 |

| Notes

1 This standard only considers fans with power less than 300 kW. The vibration assessment of fans with greater power is according to ISO 10816-3. However, standard series electric motors can have a rated power of up to 355 kW. Fans with such electric motors should be accepted according to this standard.

2 Table 1 does not apply to large diameter (usually from 2800 to 12500 mm) low-speed light axial fans used in heat exchangers, cooling towers, etc. The balancing accuracy class for such fans should be G16, and the fan category – BV-3

|

|||

When purchasing individual rotor elements (wheels or impellers) for subsequent installation on the fan, the balancing accuracy class of these elements (see table 2) should be followed, and when purchasing the fan as a whole, the results of factory vibration tests (table 4) and on-site vibration (table 5) should also be considered. Usually, these characteristics are agreed upon, so the choice of fan can be made based on its BV-category.

The category established in table 1 is typical for the normal use of fans, but in justified cases, the customer may request a fan of a different BV-category. It is recommended to specify the fan’s BV-category, balancing accuracy class, and acceptable vibration levels in the equipment supply contract.

A separate agreement between the customer and the manufacturer can be concluded regarding the fan installation conditions, so that the factory testing of the assembled fan considers the planned installation conditions at the operating site. In the absence of such an agreement, there are no restrictions on the type of base (rigid or compliant) for factory tests.

Fan Balancing

General Provisions

The fan manufacturer is responsible for balancing the fans according to the relevant regulatory document. This standard is based on the requirements of ISO 1940-1. Balancing is usually carried out on highly sensitive, specially designed balancing machines, allowing for an accurate assessment of residual imbalance.

Fan Balancing Accuracy Classes

The balancing accuracy classes for fan wheels are applied in accordance with table 2. The fan manufacturer can perform balancing for several elements in assembly, which may include, in addition to the wheel, the shaft, coupling, pulley, etc. In addition, individual assembly elements may require balancing.

Table 2 – Balancing Accuracy Classes

|

Fan Category

|

Rotor (Wheel) Balancing Accuracy Class

|

|

BV-1

|

G16

|

|

BV-2

|

G16

|

|

BV-3

|

G6.3

|

|

BV-4

|

G2.5

|

|

BV-5

|

G1.0

|

|

Note: Fans of category BV-1 can include small size fans weighing less than 224 g, for which it is difficult to maintain the specified balancing accuracy. In this case, the uniformity of mass distribution relative to the fan’s axis of rotation should be ensured by the manufacturing technology.

|

|

Fan Vibration Measurement

Measurement Requirements

General Provisions

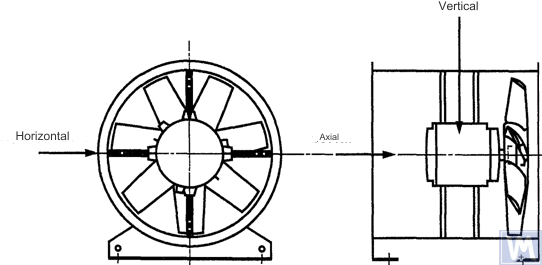

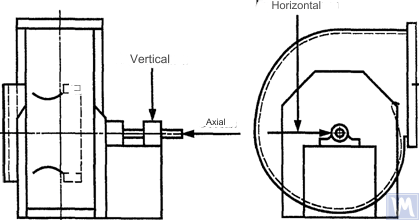

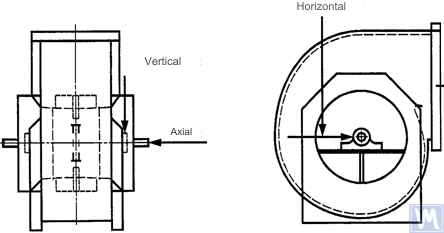

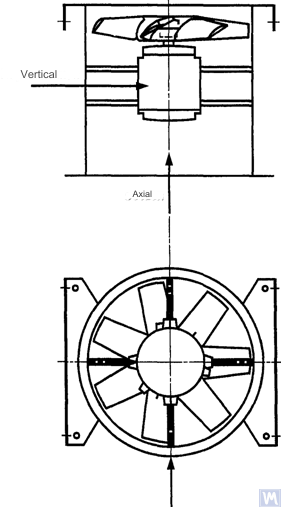

Figures 1 – 4 show some possible measurement points and directions on each fan bearing. The values given in table 4 relate to measurements in the direction perpendicular to the axis of rotation. The number and location of measurement points for both factory tests and on-site measurements are determined at the manufacturer’s discretion or by agreement with the customer. It is recommended to measure on the bearings of the fan wheel shaft (impeller). If this is not possible, the sensor should be installed in a place where the shortest mechanical connection between it and the bearing is ensured. The sensor should not be mounted on unsupported panels, the fan housing, enclosure elements, or other places not directly connected to the bearing (such measurement results can be used, but not for assessing the fan’s vibrational state, but for obtaining information about the vibration transmitted to the duct or base – see ISO 31351 and ISO 5348.

Figure 1. Location of a three-coordinate sensor for a horizontally mounted axial fan

Figure 2. Location of a three-coordinate sensor for a single-suction radial fan

Figure 3. Location of a three-coordinate sensor for a double-suction radial fan

Figure 4. Location of a three-coordinate sensor for a vertically mounted axial fan

Measurements in the horizontal direction should be carried out at a right angle to the shaft axis. Measurements in the vertical direction should be carried out at a right angle to the horizontal measurement direction and perpendicular to the fan shaft. Measurements in the longitudinal direction should be carried out parallel to the shaft axis.

Measurements using inertia-type sensors

All vibration values specified in this standard refer to measurements taken using inertia-type sensors, the signal of which reproduces the movement of the bearing housing.

The sensors used can be either accelerometers or velocity sensors. Particular attention should be paid to the correct attachment of sensors: without gaps on the support surface, without swings and resonances. The size and mass of the sensors and the attachment system should not be excessively large to avoid significant changes in the measured vibration. The total error caused by the method of sensor attachment and calibration of the measuring system should not exceed +/- 10% of the measured value.

Measurements using non-contact sensors

By agreement between the user and the manufacturer, requirements for the maximum allowable shaft displacement (see ISO 7919-1) within sliding bearings may be established. The corresponding measurements can be carried out using non-contact sensors.

In this case, the measuring system determines the displacement of the shaft surface relative to the bearing housing. It is obvious that the allowable amplitude of displacements should not exceed the value of the bearing clearance. The clearance value depends on the size and type of bearing, the load (radial or axial), and the measurement direction (some bearing designs have an elliptical hole, for which the clearance in the horizontal direction is greater than in the vertical direction). The variety of factors that need to be considered does not allow setting uniform shaft displacement limits, but some recommendations are presented in table 3. The values given in this table represent a percentage of the total radial clearance value in the bearing in each direction.

Table 3 – Maximum Relative Shaft Displacement within the Bearing

| Fan Vibrational State | Maximum Recommended Displacement, Percentage of Clearance Value (Along Any Axis) |

| Commissioning/Satisfactory State | Less than 25% |

| Warning | +50% |

| Shutdown | +70% |

| 1) Radial and axial clearance values for a specific bearing should be obtained from its supplier. | |

The given values take into account “false” displacements of the shaft surface. These “false” displacements appear in the measurement results because, in addition to the shaft vibration, mechanical runouts also affect these results if the shaft is bent or has an out-of-round shape. When using a non-contact sensor, the measurement results will also include electrical runouts determined by the magnetic and electrical properties of the shaft material at the measurement point. It is believed that during the commissioning and subsequent normal operation of the fan, the range of the sum of mechanical and electrical runouts at the measurement point should not exceed the larger of two values: 0.0125 mm or 25% of the measured displacement value. Runouts are determined by slowly rotating the shaft (at a speed of 25 to 400 rpm), when the effect of forces caused by imbalance on the rotor is negligible. To meet the established runout tolerance, additional shaft machining may be required. Non-contact sensors should, if possible, be mounted directly on the bearing housing.

The given limit values apply only to a fan operating in its nominal mode. If the fan design allows operation with variable rotational speed, higher vibration levels are possible at other speeds due to the inevitable influence of resonances.

If the fan design allows changing the blade positions relative to the airflow at the intake port, the given values should be applied for conditions with the blades fully open. It should be noted that airflow stall, especially noticeable at large blade angles relative to the intake airflow, can lead to increased vibration levels.

Fan Support System

The vibrational state of fans after installation is determined considering the support stiffness. A support is considered rigid if the first natural frequency of the “fan – support” system exceeds the rotational speed. Usually, when mounted on large concrete foundations, the support can be considered rigid, and when mounted on vibration isolators – compliant. A steel frame, often used for mounting fans, can belong to either of the two support types. In case of doubt about the fan support type, calculations or tests can be carried out to determine the system’s first natural frequency. In some cases, the fan support should be considered rigid in one direction and compliant in another.

Limits of Allowable Fan Vibration during Factory Tests

The limit vibration levels given in table 4 apply to assembled fans. They relate to narrow-band vibration velocity measurements at bearing supports for the rotational frequency used during factory tests.

Table 4 – Limit Vibration Values during Factory Tests

| Fan Category | Limit RMS Vibration Velocity, mm/s | |

| Rigid Support | Compliant Support | |

| BV-1 | 9.0 | 11.2 |

| BV-2 | 3.5 | 5.6 |

| BV-3 | 2.8 | 3.5 |

| BV-4 | 1.8 | 2.8 |

| BV-5 | 1.4 | 1.8 |

| Notes

1 The rules for converting vibration velocity units to displacement or acceleration units for narrow-band vibration are specified in Appendix A.

2 The values in this table apply to the nominal load and nominal rotational frequency of the fan operating in the mode with open inlet guide vanes. The limit values for other loading conditions should be agreed upon between the manufacturer and the customer, but it is recommended that they do not exceed the tabular values by more than 1.6 times.

|

||

Limits of Allowable Fan Vibration during On-Site Testing

The vibration of any fan at the operating site depends not only on its balancing quality. Factors related to installation, such as the mass and stiffness of the support system, will also have an influence. Therefore, the fan manufacturer is not responsible for the vibration level of the fan at its operating site unless it is specified in the contract.

Table 5 provides recommended limit values (in vibration velocity units for broadband vibration on bearing housings) for the normal operation of fans in various categories.

Table 5 – Limit Vibration Values at the Operating Site

| Fan Vibrational State | Fan Category | Limit RMS Vibration Velocity, mm/s | |

| Rigid Support | Compliant Support | ||

| Commissioning | BV-1 | 10 | 11.2 |

| BV-2 | 5.6 | 9.0 | |

| BV-3 | 4.5 | 6.3 | |

| BV-4 | 2.8 | 4.5 | |

| BV-5 | 1.8 | 2.8 | |

| Warning | BV-1 | 10.6 | 14.0 |

| BV-2 | 9.0 | 14.0 | |

| BV-3 | 7.1 | 11.8 | |

| BV-4 | 4.5 | 7.1 | |

| BV-5 | 4.0 | 5.6 | |

| Shutdown | BV-1 | __1) | __1) |

| BV-2 | __1) | __1) | |

| BV-3 | 9.0 | 12.5 | |

| BV-4 | 7.1 | 11.2 | |

| BV-5 | 5.6 | 7.1 | |

| 1) The shutdown level for fans of categories BV-1 and BV-2 is established based on long-term analysis of vibration measurement results. | |||

The vibration of new fans being commissioned should not exceed the “commissioning” level. As the fan operates, its vibration level is expected to increase due to wear processes and the cumulative effect of influencing factors. Such an increase in vibration is generally natural and should not cause concern until it reaches the “warning” level.

Upon reaching the “warning” vibration level, it is necessary to investigate the causes of the increased vibration and determine measures to reduce it. Fan operation in this state should be under constant monitoring and limited to the time required to identify measures to eliminate the causes of increased vibration.

If the vibration level reaches the “shutdown” level, measures to eliminate the causes of increased vibration must be taken immediately, otherwise, the fan should be stopped. Delaying bringing the vibration level to an acceptable level can lead to bearing damage, cracks in the rotor, and at welding points of the fan housing, ultimately resulting in the fan’s destruction.

When assessing the fan’s vibrational state, it is essential to monitor changes in vibration levels over time. A sudden change in vibration level indicates the need for immediate fan inspection and maintenance measures. When monitoring vibration changes, transitional processes caused by, for example, lubricant replacement or maintenance procedures should not be considered.

The Influence of the Assembly Procedure

In addition to wheels, fans include other rotating elements that can affect the fan’s vibration level: drive pulleys, belts, couplings, motor rotors, or other drive devices. If the order conditions require the supply of the fan without a drive device, it may be impractical for the manufacturer to conduct assembly tests to determine vibration levels. In such a case, even if the manufacturer has balanced the fan wheel, there is no certainty that the fan will run smoothly until the fan shaft is connected to the drive and the entire machine is tested for vibration during commissioning.

Usually, after assembly, additional balancing is required to reduce the vibration level to an acceptable level. For all new fans of categories BV-3, BV-4, and BV-5, it is recommended to measure vibration for the assembled machine before commissioning. This will establish a baseline and outline further maintenance measures.

Fan manufacturers are not responsible for the impact on vibration of drive parts installed after factory testing.

Vibration Measurement Tools and Calibration

Measurement Tools

The measurement tools and balancing machines used must be verified and meet the task requirements. The interval between verifications is determined by the manufacturer’s recommendations for the measurement (test) tools. The condition of the measurement tools must ensure their normal operation throughout the testing period.

Personnel working with measurement tools must have sufficient skills and experience to detect potential malfunctions and deterioration in the quality of the measurement tools.

Calibration

All measurement tools must be calibrated according to standards. The complexity of the calibration procedure may vary from a simple physical inspection to the calibration of the entire system. Corrective masses used to determine the residual imbalance according to ISO 1940-1 can also be used for calibrating measurement tools.

Documentation

Balancing

Upon request, if provided for by the contract terms, a fan balancing test report can be provided to the customer, which is recommended to include the following information:

– Name of the balancing machine manufacturer, model number;

– Type of rotor installation: between supports or cantilevered;

– Balancing method: static or dynamic;

– Mass of the rotating parts of the rotor assembly;

– Residual imbalance in each correction plane;

– Allowable residual imbalance in each correction plane;

– Balancing accuracy class;

– Acceptance criteria: accepted/rejected;

– Balancing certificate (if necessary).

– Name of the balancing machine manufacturer, model number;

– Type of rotor installation: between supports or cantilevered;

– Balancing method: static or dynamic;

– Mass of the rotating parts of the rotor assembly;

– Residual imbalance in each correction plane;

– Allowable residual imbalance in each correction plane;

– Balancing accuracy class;

– Acceptance criteria: accepted/rejected;

– Balancing certificate (if necessary).

Vibration

Upon request, if provided for by the contract terms, a fan vibration test report can be provided to the customer, which is recommended to include the following information:

– Measurement tools used;

– Vibration sensor attachment method;

– Operating parameters of the fan (airflow, pressure, power);

– Fan rotational frequency;

– Support type: rigid or compliant;

– Measured vibration:

1) Vibration sensor positions and measurement axes,

2) Measurement units and vibration reference levels,

3) Measurement frequency range (narrow or broad frequency band);

– Allowable vibration level(s);

– Measured vibration level(s);

– Acceptance criteria: accepted/rejected;

– Vibration level certificate (if necessary).

– Measurement tools used;

– Vibration sensor attachment method;

– Operating parameters of the fan (airflow, pressure, power);

– Fan rotational frequency;

– Support type: rigid or compliant;

– Measured vibration:

1) Vibration sensor positions and measurement axes,

2) Measurement units and vibration reference levels,

3) Measurement frequency range (narrow or broad frequency band);

– Allowable vibration level(s);

– Measured vibration level(s);

– Acceptance criteria: accepted/rejected;

– Vibration level certificate (if necessary).

METHODS OF BALANCING FANS ON A BALANCING MACHINE

B.1. Direct Drive Fan

B.1.1. General Provisions

The fan wheel, which is mounted directly on the motor shaft during assembly, should be balanced according to the same rule for accounting for the keyway effect as for the motor shaft.

Motors from previous years of production could be balanced using a full keyway. Currently, motor shafts are balanced using a half-keyway, as prescribed by ISO 31322, and marked with the letter H (see ISO 31322).

B.1.2. Motors Balanced with a Full Keyway

The fan wheel, mounted on the motor shaft balanced with a full keyway, should be balanced without a key on a tapered arbor.

B.1.3. Motors Balanced with a Half-Keyway

For the fan wheel mounted on the motor shaft balanced with a half-keyway, the following options are possible:

a) if the wheel has a steel hub, cut a keyway in it after balancing;

b) balance on a tapered arbor with a half-key inserted into the keyway;

c) balance on an arbor with one or more keyways (see B.3), using full keys.

a) if the wheel has a steel hub, cut a keyway in it after balancing;

b) balance on a tapered arbor with a half-key inserted into the keyway;

c) balance on an arbor with one or more keyways (see B.3), using full keys.

B.2. Fans Driven by Another Shaft

Where possible, all rotating elements, including the fan shaft and pulley, should be balanced as a single unit. If this is impractical, balancing should be performed on an arbor (see B.3) using the same keyway accounting rule as for the shaft.

B.3. Arbor

The arbor on which the fan wheel is mounted during balancing must meet the following requirements:

a) be as light as possible;

b) be in a balanced state, ensured by appropriate maintenance and regular inspections;

c) preferably be tapered to reduce errors associated with eccentricity, resulting from the tolerances of the hub hole and arbor dimensions. If the arbor is tapered, the true position of the correction planes relative to the bearings should be considered in the imbalance calculations.

a) be as light as possible;

b) be in a balanced state, ensured by appropriate maintenance and regular inspections;

c) preferably be tapered to reduce errors associated with eccentricity, resulting from the tolerances of the hub hole and arbor dimensions. If the arbor is tapered, the true position of the correction planes relative to the bearings should be considered in the imbalance calculations.

If it is necessary to use a cylindrical arbor, it should have a keyway cut into it, into which a full key is inserted to transmit the torque from the arbor to the fan wheel.

Another option is to cut two keyways on opposite ends of the shaft diameter, allowing the use of the reverse balancing method. This method involves the following steps. First, measure the wheel imbalance by inserting a full key into one keyway and a half-key into the other. Then rotate the wheel 180° relative to the arbor and measure its imbalance again. The difference between the two imbalance values is due to the residual imbalance of the arbor and the universal drive joint. To obtain the true rotor imbalance value, take half the difference of these two measurements.

SOURCES OF FAN VIBRATION

There are many sources of vibration within the fan, and vibration at certain frequencies can be directly linked to specific design features of the machine. This appendix only covers the most common vibration sources observed in most types of fans. The general rule is that any looseness in the support system causes deterioration in the fan’s vibrational state.

Fan Imbalance

This is the primary source of fan vibration; it is characterized by the presence of a vibration component at the rotational frequency (first harmonic). The cause of imbalance is that the axis of the rotating mass is eccentric or angled to the axis of rotation. This can be caused by uneven mass distribution, the sum of tolerances on the dimensions of the hub hole and shaft, shaft bending, or a combination of these factors. Vibration caused by imbalance mainly acts in the radial direction.

Temporary shaft bending can result from uneven mechanical heating – due to friction between rotating and stationary elements – or electrical nature. Permanent bending can result from changes in material properties or misalignment of the shaft and fan wheel when the fan and motor are separately mounted.

During operation, the fan wheel imbalance can increase due to particle deposition from the air. When operating in an aggressive environment, imbalance can result from uneven erosion or corrosion of the wheel.

Imbalance can be corrected by additional balancing in the appropriate planes, but before performing the balancing procedure, the sources of imbalance should be identified, eliminated, and the machine’s vibrational stability checked.

Fan and Motor Misalignment

This defect can occur when the motor and fan shafts are connected via a belt drive or flexible coupling. Misalignment can sometimes be identified by characteristic vibration frequency components, usually the first and second harmonics of the rotational frequency. In the case of parallel misalignment of the shafts, vibration primarily occurs in the radial direction, while if the shafts intersect at an angle, longitudinal vibration may become dominant.

If the shafts are connected at an angle and rigid couplings are used, alternating forces begin to act in the machine, causing increased wear of the shafts and couplings. This effect can be significantly reduced by using flexible couplings.

Fan Vibration Due to Aerodynamic Excitation

Vibration excitation can be caused by the interaction of the fan wheel with stationary elements of the design, such as guide vanes, motor, or bearing supports, incorrect gap values, or improperly designed air intake and exhaust structures. A characteristic feature of these sources is the occurrence of periodic vibration associated with the wheel’s rotational frequency, against the background of random fluctuations in the interaction of the wheel blades with the air. Vibration can be observed at the blade frequency harmonics, which is the product of the wheel’s rotational frequency and the number of wheel blades.

Aerodynamic instability of the airflow, caused by its stall from the blade surface and subsequent vortex formation, causes broadband vibration, the spectrum shape of which changes depending on the fan’s load.

Aerodynamic noise is characterized by the fact that it is not related to the wheel’s rotational frequency and can occur at subharmonics of the rotational frequency (i.e., at frequencies below the rotational frequency). In this case, significant vibration of the fan housing and ducts can be observed.

If the aerodynamic system of the fan is poorly matched with its characteristics, sharp impacts may occur in it. These impacts are easily distinguishable by ear and are transmitted as impulses to the fan support system.

If the above-mentioned causes lead to blade vibration, its nature can be investigated by installing sensors in different parts of the structure.

Fan Vibration Due to Whirl in the Oil Layer

Whirls that may occur in the lubrication layer of sliding bearings are observed at a characteristic frequency slightly below the rotor’s rotational frequency unless the fan operates at a speed exceeding the first critical. In the latter case, oil wedge instability will be observed at the first critical speed, and sometimes this effect is called resonant whirl.

Sources of Electrical Nature Fan Vibration

Uneven heating of the motor rotor can cause it to bend, leading to imbalance (manifesting at the first harmonic).

In the case of an asynchronous motor, the presence of a component at a frequency equal to the rotational frequency multiplied by the number of rotor plates indicates defects related to the stator plates, and vice versa, components at a frequency equal to the rotational frequency multiplied by the number of rotor plates indicate defects related to the rotor plates.

Many vibration components of electrical nature are characterized by their immediate disappearance when the power supply is turned off.

Fan Vibration Due to Belt Drive Excitation

Generally, there are two types of problems related to belt drives: when the drive’s operation is influenced by external defects and when the defects are in the belt itself.

In the first case, although the belt vibrates, this is due to forcing forces from other sources, so replacing the belt will not produce the desired results. Common sources of such forces are imbalance in the drive system, pulley eccentricity, misalignment, and loosened mechanical connections. Therefore, before changing the belts, vibration analysis should be carried out to identify the excitation source.

If the belts respond to external forcing forces, their vibration frequency will most likely be the same as the excitation frequency. In this case, the excitation frequency can be determined using a stroboscopic lamp, adjusting it so that the belt appears stationary in the lamp’s light.

In the case of a multi-belt drive, unequal belt tension can lead to a significant increase in the transmitted vibration.

Cases where the vibration sources are the belts themselves are related to their physical defects: cracks, hard and soft spots, dirt on the belt surface, missing material from its surface, etc. For V-belts, changes in their width will cause the belt to ride up and down the pulley track, creating vibration due to changing its tension.

If the vibration source is the belt itself, the vibration frequencies are usually the harmonics of the belt’s rotational frequency. In a specific case, the excitation frequency will depend on the nature of the defect and the number of pulleys, including tensioners.

In some cases, the vibration amplitude may be unstable. This is especially true for multi-belt drives.

Mechanical and electrical defects are sources of vibration, which subsequently convert into airborne noise. Mechanical noise can be associated with fan or motor imbalance, bearing noise, axis alignment, duct wall and housing panel vibrations, damper blade vibrations, blade, damper, pipe, and support vibrations, as well as transmission of mechanical vibrations through the structure. Electrical noise is related to various forms of electrical energy conversion: 1) Magnetic forces are determined by the magnetic flux density, the number and shape of the poles, and the geometry of the air gap; 2) Random electrical noise is determined by brushes, arcing, electrical sparks, etc.

Aerodynamic noise can be associated with vortex formation, pressure pulsations, air resistance, etc., and can have both broadband and narrowband nature. Broadband noise can be caused by: a) blades, dampers, and other obstacles in the airflow path; b) fan rotation as a whole, belts, slits, etc.; c) sudden changes in airflow direction or duct cross-section, differences in flow velocities, flow separation due to boundary effects, flow compression effects, etc. Narrowband noise can be caused by: a) resonances (organ pipe effect, string vibrations, panel, structural element vibrations, etc.); b) vortex formation on sharp edges (air column excitation); c) rotations (siren effect, slits, holes, slots on rotating parts).

Impacts created by contact between various mechanical elements of the structure produce noise similar to that produced by a hammer blow, thunder roll, resonating empty box, etc. Impact sounds can be heard from gear teeth impacts and defective belt claps. Impact impulses can be so fleeting that to distinguish periodic impact impulses from transient processes, special high-speed recording equipment is needed. The area where many impact impulses occur, the superimposition of their peaks creates a constant hum effect.

Dependence of Vibration on Fan Support Type

The correct choice of fan support or foundation design is necessary for its smooth, trouble-free operation. To ensure the alignment of rotating components when installing the fan, motor, and other drive devices, a steel frame or reinforced concrete base is used. Sometimes an attempt to save on support construction leads to the inability to maintain the required alignment of the machine components. This is especially unacceptable when vibration is sensitive to alignment changes, particularly for machines consisting of separate parts connected by metal fasteners.

The foundation on which the base is laid can also influence the fan and motor vibration. If the foundation’s natural frequency is close to the fan or motor’s rotational frequency, the foundation will resonate during fan operation. This can be detected by measuring vibration at several points across the foundation, surrounding floor, and fan supports. Often in resonance conditions, the vertical vibration component significantly exceeds the horizontal one. Vibration can be dampened by making the foundation stiffer or increasing its mass. Even if imbalance and misalignment are eliminated, allowing to reduce forcing forces, significant vibration preconditions may still exist. This means that if the fan, together with its support, is close to resonance, achieving acceptable vibration values will require more precise balancing and more accurate shaft alignment than typically required for such machines. This situation is undesirable and should be avoided by increasing the support or concrete block’s mass and/or stiffness.

Vibration Condition Monitoring and Diagnostics Guide

The main principle of machine vibration condition monitoring (hereinafter referred to as the condition) is to observe the results of properly planned measurements to identify a trend of increasing vibration levels and consider it from the perspective of potential problems. Monitoring is applicable in situations where damage develops slowly, and the mechanism’s condition deterioration manifests through measurable physical signs.

Fan vibration, resulting from the development of physical defects, can be monitored at certain intervals, and when an increase in vibration level is detected, the observation frequency can be increased, and a detailed condition analysis can be conducted. In this case, the causes of vibration changes can be identified based on vibration frequency analysis, which allows determining the necessary measures and planning their implementation long before the damage becomes severe. Usually, measures are considered necessary when the vibration level increases by 1.6 times or by 4 dB compared to the baseline level.

The condition monitoring program consists of several stages, which can be briefly formulated as follows:

a) identify the fan’s condition and determine the baseline vibration level (it may differ from the level obtained during factory tests due to different installation methods, etc.);

b) select vibration measurement points;

c) determine the observation (measurement) frequency;

d) establish the information registration procedure;

e) determine the criteria for assessing the fan’s vibrational state, limit values for absolute vibration and vibration changes, summarize the experience of operating similar machines.

a) identify the fan’s condition and determine the baseline vibration level (it may differ from the level obtained during factory tests due to different installation methods, etc.);

b) select vibration measurement points;

c) determine the observation (measurement) frequency;

d) establish the information registration procedure;

e) determine the criteria for assessing the fan’s vibrational state, limit values for absolute vibration and vibration changes, summarize the experience of operating similar machines.

Since fans typically operate without any problems at speeds not approaching the critical, the vibration level should not significantly change with slight speed or load changes, but it is important to note that when the fan operates with variable rotational speed, the established vibration limit values apply to the maximum operating rotational speed. If the maximum rotational speed cannot be reached within the established vibration limit, this may indicate the presence of a serious problem and require a special investigation.

Some diagnostic recommendations provided in Appendix C are based on fan operation experience and are intended for sequential application when analyzing the causes of increased vibration.

To qualitatively assess the vibration of a specific fan and determine guidelines for further actions, the vibration condition zone boundaries established by ISO 10816-1 can be used.

It is expected that for new fans, their vibration levels will be below the limit values given in table 3. These values correspond to the boundary of zone A of the vibration condition according to ISO 10816-1. Recommended values for warning and shutdown levels are established based on the analysis of information collected on specific types of fans.

COMPLIANCE INFORMATION

REFERENCE INTERNATIONAL STANDARDS USED AS NORMATIVE REFERENCES IN THIS STANDARD

Table H.1

|

Designation of the Reference Interstate Standard

|

Designation and Title of the Reference International Standard and the Conditional Designation of Its Degree of Compliance with the Reference Interstate Standard

|

|

ISO 1940-1-2007

|

ISO 1940-1:1986. Vibration. Requirements for the Balancing Quality of Rigid Rotors. Part 1. Determination of Allowable Imbalance (IDT)

|

|

ISO 5348-2002

|

ISO 5348:1999. Vibration and Shock. Mechanical Mounting of Accelerometers (IDT)

|

|

ISO 7919-1-2002

|

ISO 7919-1:1996. Vibration of Non-Reciprocating Machines. Measurements on Rotating Shafts and Criteria for Evaluation. Part 1. General Guidelines (IDT)

|

|

ISO 10816-1-97

|

ISO 10816-1:1995. Vibration. Evaluation of Machine Condition by Vibration Measurements on Non-Rotating Parts. Part 1. General Guidelines (IDT)

|

|

ISO 10816-3-2002

|

ISO 10816-3:1998. Vibration. Evaluation of Machine Condition by Vibration Measurements on Non-Rotating Parts. Part 3. Industrial Machines with a Nominal Power of More Than 15 kW and Nominal Speeds of 120 to 15000 rpm, in-Situ Measurements (IDT)

|

|

ISO 10921-90

|

ISO 5801:1997. Industrial Fans. Performance Testing Using Standardized Ducts (NEQ)

|

|

ISO 19534-74

|

ISO 1925:2001. Vibration. Balancing. Vocabulary (NEQ)

|

|

ISO 24346-80

|

ISO 2041:1990. Vibration and Shock. Vocabulary (NEQ)

|

|

ISO 31322-2006 (ISO 8821:1989)

|

ISO 8821:1989. Vibration. Balancing. Guidelines for Accounting for the Keyway Effect When Balancing Shafts and Fitted Parts (MOD)

|

|

ISO 31351-2007 (ISO 14695:2003)

|

ISO 14695:2003. Industrial Fans. Vibration Measurement Methods (MOD)

|

|

Note: The following conditional designations of the standard’s compliance degree are used in this table: IDT – identical standards;

|

|

0 Comments