Introduction

The importance of dynamic balancing in rotary machinery, particularly in blower systems, is well understood by industry professionals. Unbalanced blower rotors can lead to numerous complications including increased wear and tear, noise pollution, and high energy consumption. This paper aims to delve into the specific issues relating to elevated vibration in different types of blowers—squirrel cage, blower rotors, blower wheels, turbine type, rotary vane, lobe, and centrifugal blowers—and discuss the balancing process using the portable vibration analyzer Balanset-1A.

Issues Associated with Elevated Vibration in Blower Systems

- Component Fatigue: Excessive vibration stresses material, leading to premature failure and fatigue.

- Operational Inefficiency: An unbalanced rotor results in greater energy consumption and reduced throughput.

- Accelerated Bearing Wear: Elevated vibrations lead to increased bearing wear, necessitating frequent maintenance or replacement.

- Noise Pollution: Imbalance in the rotor leads to increased noise levels, which could be hazardous in a workplace setting.

- Structural Resonance: High levels of vibration can lead to a resonance phenomenon, causing even further escalation in vibration levels and risking catastrophic failure.

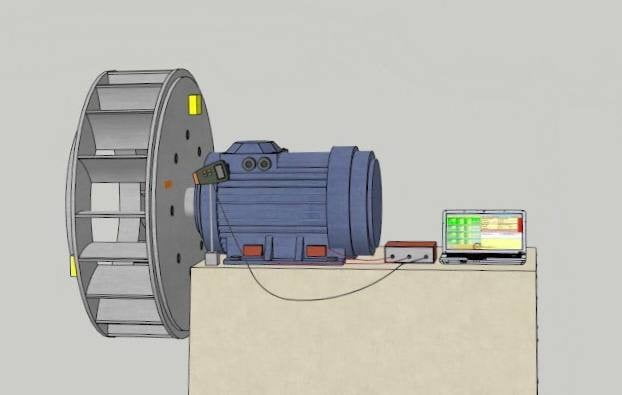

a two-plane dynamic balancing process for an industrial radial fan. The procedure aims to eliminate vibration and imbalance in the fan’s impeller. Balanset-1 Vibromera

Process of Dynamic Balancing Using Balanset-1A

- Initial Diagnostic Assessment: Utilizing Balanset-1A’s vibration and rotational speed sensors, initial vibration levels are measured to establish a baseline.

- In-Situ Balancing: The key advantage of using Balanset-1A is the capability to perform balancing in the machine’s own bearings, eliminating the need for rotor dismantling.

- Trial Weight Attachment: Small weights are attached at points on the rotor to measure how the system reacts, enabling the software to calculate correction factors.

- Data Analysis and Calculations: Balanset-1A processes the acquired data to calculate the exact mass and angular position of the weights required to achieve balance.

- Final Verification: Upon completion of corrective weight installations, a final run is conducted to ensure the vibrations have been effectively mitigated.

portable dynamic balancer, vibration analyzer “Balanset-1A”

Advantages of In-Situ Balancing with Balanset-1A

- Time and Cost Efficiency: Eliminates the need for rotor removal and reinstallation, thus saving significant downtime and associated costs.

- Elimination of Reassembly Errors: By avoiding disassembly, potential errors in reassembly or defects due to transportation are eliminated.

- Precision: Balanset-1A’s high-resolution sensors provide precise readings, enabling more accurate weight adjustments.

Conclusion

Dynamic balancing is a non-negotiable maintenance protocol for various types of blower systems to ensure optimal efficiency and longevity. Utilizing advanced portable vibration analyzers like Balanset-1A, in-situ balancing can be accomplished without the need for rotor removal, resulting in considerable time and cost savings. Given the array of complications associated with rotor imbalance, investing in such specialized balancing methods is both a safe and economically sound decision.

Portable balancer, vibration analyzer

0 Comments