Balancing Instrument at the Price of a Vibrometer

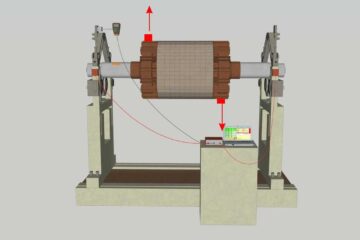

Is it possible? With determination – YES! Balancing instruments rightfully occupy a special place among the wide range of equipment used for vibroacoustic measurements. This is largely due to the fact that this class of instruments, in addition to performing metrological functions, also fulfills a technological role. Essentially, it is technological equipment used to reduce the imbalance of rotary mechanisms. As a result, it offers high economic efficiency, allowing for significant quality improvement of products with relatively small capital investments when implementing balancing equipment. This is especially true for industries where a significant amount of rotary equipment is operated or Read more