Crashers Example Mulchers rotors

Mulcher rotor balancing process

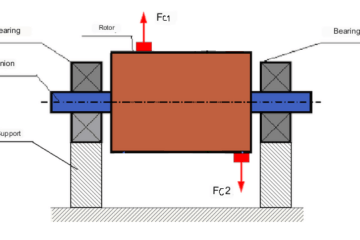

Why Rotor Balancing of Mulchers is Necessary Rotor balancing of mulchers is essential not only for reducing vibration and noise during operation but also for preventing premature wear of bearings, reducing the load on the drive, and extending the overall lifespan of the machine. Using a portable balancer allows for onsite balancing without the need to dismantle the mulcher and remove the rotor. Preparation for Balancing Before starting the balancing process, it is necessary to conduct a thorough inspection of the mulcher. It is important to check the bearings for play, inspect the housing for cracks, and ensure that all Read more…