🔧 Complete Guide to Crusher and Mill Balancing

From Theory to Practice: Save up to 50% on Repairs, Extend Equipment Life by 3x

💡 Did You Know?

An imbalance of just 100 grams on a crusher rotor creates an impact force equivalent to 50 hammer blows per second on your bearings!

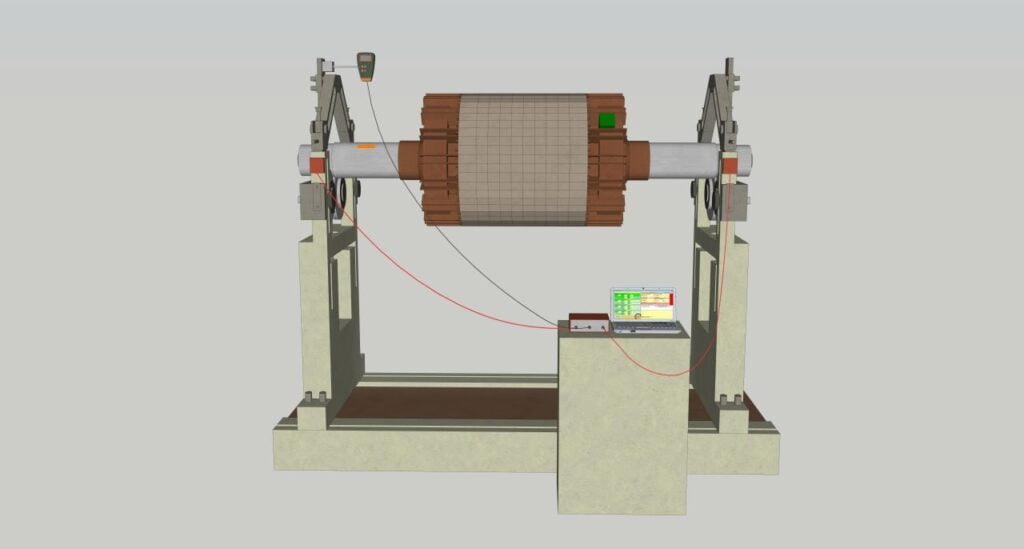

Balancing the crusher using the Balanset-1A vibration analyzer

🎯 Why Is Balancing Critically Important?

Cost Savings

Reduce repair costs by up to 50% and extend maintenance intervals by 3-5 times

Energy Efficiency

Reduce energy consumption by 5-15% by eliminating parasitic loads

Safety

Prevent emergency situations and protect personnel from injuries

📊 Equipment Types and Balancing Features

Crusher and Mill Types

Impact Crushers

The most common type requiring regular balancing due to intensive wear of impact elements

Hammer Mills

Free-hanging hammers require special balancing methodology

Ball Mills

Large mass and special loading conditions require careful approach

Mulchers and Shredders

Extreme operating conditions with sudden imbalance changes from broken elements

⚠️ Consequences of Ignoring Imbalance

❌ WITHOUT Balancing

- 🔴 Bearings last 5-10k hours

- 🔴 Repair costs $50-100k/year

- 🔴 Downtime 10-15 days/year

- 🔴 Risk of accidents and injuries

- 🔴 Increased energy consumption

✅ WITH Regular Balancing

- 🟢 Bearings last 30-50k hours

- 🟢 Repair costs $10-20k/year

- 🟢 Downtime 2-3 days/year

- 🟢 Safe operation

- 🟢 Optimal energy consumption

🔬 Physics of Imbalance: Understanding the Problem

Types of Imbalance

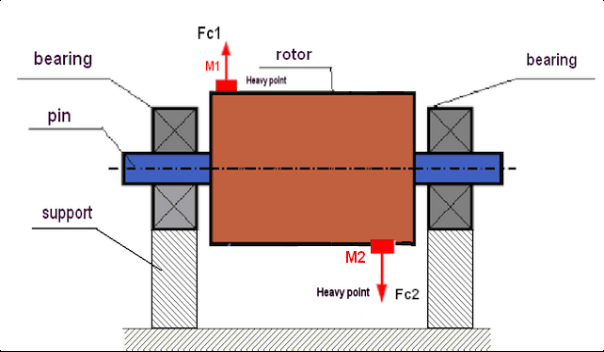

Static imbalance - displacement of the mass center from the rotation axis. Typical for disk rotors (L/D < 0.25).

Dynamic imbalance - combination of static and couple imbalance. Requires two-plane balancing.

⚠️ Critical Speeds and Resonance

Operation near resonant frequencies can lead to catastrophic equipment failure. Balancing in the resonance zone is IMPOSSIBLE!

🚀 Revolutionary Solution: Balanset-1A

Field Balancing Advantages

| Parameter | Traditional Method | Balanset-1A |

|---|---|---|

| Balancing time | 3-7 days | 2-4 hours |

| Disassembly required | Yes | No |

| Work cost | $5000-15000 | $500-1500 |

| Accuracy | High | High |

📋 Step-by-Step Balancing Procedure

Preliminary Diagnostics

- Vibration spectrum analysis (FFT mode)

- Mechanical condition check

- Run-out test to identify resonances

Equipment Preparation

- Thorough rotor cleaning

- Check and replace worn elements

- Install vibration sensors

- Set up tachometer sensor

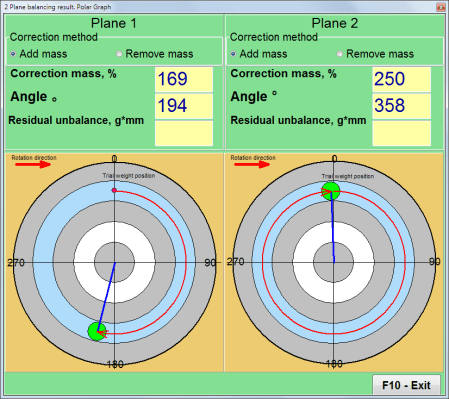

Dynamic Balancing

- Initial run and vibration measurement

- Trial weight installation

- Correction weight calculation

- Install correction weights

- Verification run

Quality Assessment

- Check compliance with ISO 1940-1

- Document results

- Recommendations for further operation

💰 Economic Justification

Balanset-1A ROI Calculation

Equipment cost: €1751

| Parameter | Value |

|---|---|

| Cost of one contractor balancing | $1500 |

| Balancing frequency per year | 4 times |

| Annual savings | $6000 |

| Additional bearing savings | $10000-30000 |

🔧 Typical Problem Solutions

Problem: "Floating" Readings

Causes: mechanical looseness, bearing wear, resonance

Solution: systematic check and elimination of each cause

Problem: Cannot Achieve Tolerance

Causes: other defects present (misalignment, bearing defects)

Solution: comprehensive vibration diagnostics, eliminate related defects

❓ Frequently Asked Questions

How often is balancing needed?

Recommended every 3-6 months for intensively operated equipment or when vibration appears.

Can it be done independently?

Yes! With Balanset-1A, balancing is accessible even to personnel without special training after brief instruction.

What balancing class is required?

For most crushers - G6.3 per ISO 1940-1, for high-speed centrifuges - G2.5.

✅ Your Action Plan

- Purchase balancing equipment

- Train 1-2 specialists

- Create a regular inspection schedule

- Track the economic impact

Remember: Every day of unbalanced equipment operation brings expensive repairs closer!

We guarantee high-quality balancing and technical support via WhatsApp

0 Comments