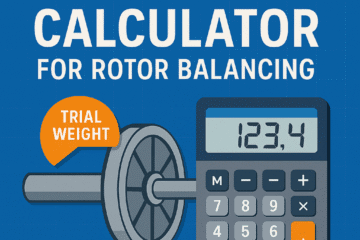

Online Vector Calculator for Rotor Balancing

Vector Calculator Vector Calculator Vector A Mass, g Angle, deg Vector B Mass, g Angle, deg Operation + Add − Subtract ±180° Opposite k× Scale → X, Y Multiplier k: Calculate How this calculator works + What is this calculator for? This calculator performs vector operations using polar coordinates (magnitude and angle). It is designed for rotor balancing applications where imbalance is measured as a mass at a specific angular position. The calculator helps combine multiple imbalance readings, determine correction weight placement, and convert between coordinate systems. Input format Each vector is defined by two values: mass (in grams or Read more