Trial Weight Calculator

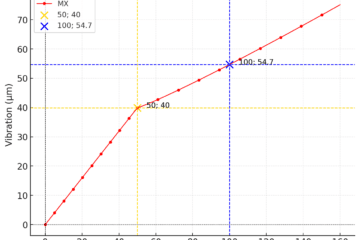

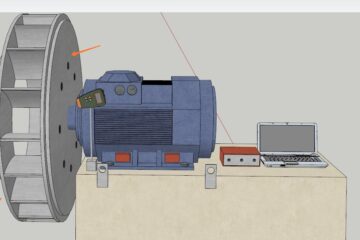

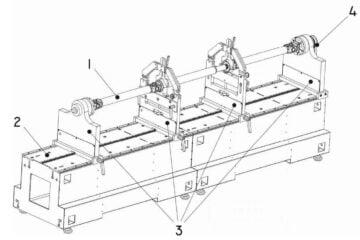

Trial Weight Calculator Trial Weight Calculator Calculation of trial weight mass for rotor balancing Mt = Mr × Ksupp × Kvib / (Rt × (N/100)²) where: Mt – trial weight mass, g Mr – rotor mass Ksupp – support stiffness coefficient (1-5) Kvib – vibration level coefficient Rt – trial weight installation radius N – rotor speed, rpm Rotor mass (Mr) grams kilograms Trial weight installation radius (Rt) mm cm Rotor speed (N), rpm Support stiffness coefficient (Ksupp) 1.0 Vibration level, mm/sec Enter value Kvib = 1.0 Calculate Clear ✓ Calculation Result Calculator Description This calculator is designed to calculate Read more…