Dynamic Balancing of Flail Mower and Forestry Mulcher Rotors

Is your flail mower or mulcher shaking itself apart? You're not alone. Studies estimate that about 50% of mechanical vibration issues are caused by unbalanced rotors. Those vibrations aren't just annoying—they can wreak havoc on your equipment and budget. In this article, we'll explain what rotor balancing is, why it's so important, and how to balance the rotors of flail mowers and forestry mulchers to eliminate destructive vibration.

What Is Rotor Balancing?

Rotor balancing is the process of adjusting the mass distribution of a rotor to reduce or eliminate the vibrations that occur when it rotates. In simple terms, it means adding or removing weight so that the rotor's weight is evenly distributed around its axis. Properly performed balancing extends the life of the machine, reduces noise and vibration, and prevents premature wear of bearings and other components.

Why Balancing Is Important: Dangers and Costs

Excessive vibration in a flail mower or mulcher is often underestimated by operators. However, ignoring rotor imbalance can lead to serious problems. According to ISO 1940-1 standards regarding balance quality grades, agricultural rotors typically fall under grade G16 or G6.3. In practical terms, vibration velocity exceeding 10 mm/s (RMS) is considered destructive and dangerous for this type of equipment, while a smooth-running machine should ideally be under 4.5 mm/s.

Here are some common signs and consequences of an unbalanced rotor:

- Increased equipment wear: Constant vibration accelerates the wear of mechanical components like bearings, gears, and shafts. This can lead to more frequent repairs and part replacements, driving up operating costs.

- Bearing failures and housing damage: Vibration causes bearings to overheat and break down quickly. The resulting looseness ("play") in worn bearings further increases vibration. You might find yourself replacing bearings often. Worse, the bearing seats (housings) can get wallowed out and damaged, requiring extensive repair.

- Cracks and leaks: Prolonged vibration can crack the mower or mulcher's frame and body welds, potentially throwing the whole assembly out of alignment. Vibration also loosens hydraulic fittings, causing fluid leaks.

- Loosened bolts and fasteners: Nuts, bolts, and screws will continually work themselves loose under vibration. This can lead to dangerous situations if critical parts detach or fail suddenly.

- Inefficient operation: An unbalanced rotor wastes energy. The engine or PTO has to work harder to spin it, which means higher fuel consumption for the same amount of work.

- Operator discomfort and fatigue: Excessive vibration makes the machine uncomfortable to operate. The operator might experience numbness or fatigue from constant shaking.

- Increased risk of accidents: If vibration is severe, it can contribute to loss of control or cause components to fail catastrophically.

- Damage to the tractor: The vibration transfers to the tractor through the hitch or PTO. Over time, it can shake loose the tractor's own bolts, joints, and mounts.

- Unexpected downtime: Ultimately, an unbalanced rotor can put your equipment out of commission without warning.

In essence, running a flail mower with an unbalanced rotor is a recipe for wear and tear. Even a small imbalance can translate into huge forces: for example, a mere 35 gram (1.25 ounce) weight imbalance at a 15 cm (6 inch) radius spinning at 2,000 RPM can exert over 22 kg (50 pounds) of extra force on the bearings, potentially cutting bearing life by about 30%.

The Cost of Ignoring Vibration (ROI)

Consider the financial impact of operating an unbalanced machine. A simple replacement of quality bearings might cost €50–€100 per set, but the real cost lies in the downtime. If a breakdown stops work for a day, you might lose €500–€1,000 in revenue or contractual penalties. In a worst-case scenario, catastrophic failure can ruin the rotor shaft itself, costing upwards of €1,500–€3,000 to replace. Investing in balancing maintenance prevents these expenses.

As a real-world example, I knew of a company whose mechanics were replacing mower bearings almost every morning. They resorted to buying the cheapest bearings and swapping them daily, because even high-quality bearings would get shredded by the extreme vibration in a matter of days. The state of their mulching equipment was shocking: it became a Frankenstein's monster of welded reinforcements just to hold it together. The plastic panels in the tractor's cab visibly shook in waves from the vibration, and the poor operator felt like he was still vibrating for a while after stepping out of the machine. This is the kind of situation you want to avoid!

Can You Balance a Flail Mower Rotor Without a Special Machine?

In short: You can partially balance a rotor by hand (static balancing), but you cannot fully balance a flail mower rotor without specialized dynamic balancing equipment. Many people have tried the "old school" method: they place the rotor on knife-edge supports and let it rotate freely; when the heavy side turns down, they weld a weight on the opposite side until the rotor no longer rolls on its own. This traditional method can correct a static imbalance.

For static balancing of a rotor, the technique is effective if the rotor is relatively narrow (short length compared to its diameter). For example, you can statically balance things like brake discs, grinding wheels, or single-belt pulleys using this method.

However, for long rotors (like the drum shaft of a flail mower or a forestry mulcher), static balancing is not enough. Imagine one end of the rotor has a heavy spot at the top, and the other end has a heavy spot at the bottom. When the rotor is sitting still, those opposing forces balance out. But the moment you spin that rotor at operating speed, centrifugal forces pull those heavy spots outward in different planes, and the rotor will vibrate. This type of imbalance is called dynamic imbalance. Static methods can't correct it.

The only way to fix dynamic imbalance is with proper dynamic balancing equipment. A dynamic balancer (either a portable device or a full-size balancing machine) can identify imbalance in each plane of the rotor and tell you exactly where and how much weight to add or remove. In summary, long flail mower rotors require two-plane dynamic balancing with specialized tools to truly eliminate vibration.

Preparation Before Balancing

Before you even attach a sensor, you must ensure the machine is mechanically sound. Balancing cannot fix a broken machine. Follow this checklist:

- Clean the Rotor: Remove all dried mud, wrapped wire, or vegetation. Even a small amount of caked-on dirt acts as a counterweight and will throw off your results.

- Inspect Bearings: Check for play (looseness) or noise. Worn bearings will cause erratic readings. If bearings are bad, replace them first.

- Check Flails/Hammers: Ensure all cutters are present and move freely. If a hammer is broken or missing, replace it (and its opposite pair) before balancing.

- Structural Check: Look for cracks in the rotor tube or frame. These must be repaired before balancing.

- Always turn off the engine and remove the key (Lockout/Tagout) before welding weights or touching the rotor.

- Wear appropriate eye protection, especially when welding or grinding.

- During test runs (spinning the rotor), ensure all personnel are at a safe distance and clear of the plane of rotation in case a loose weight or debris is ejected.

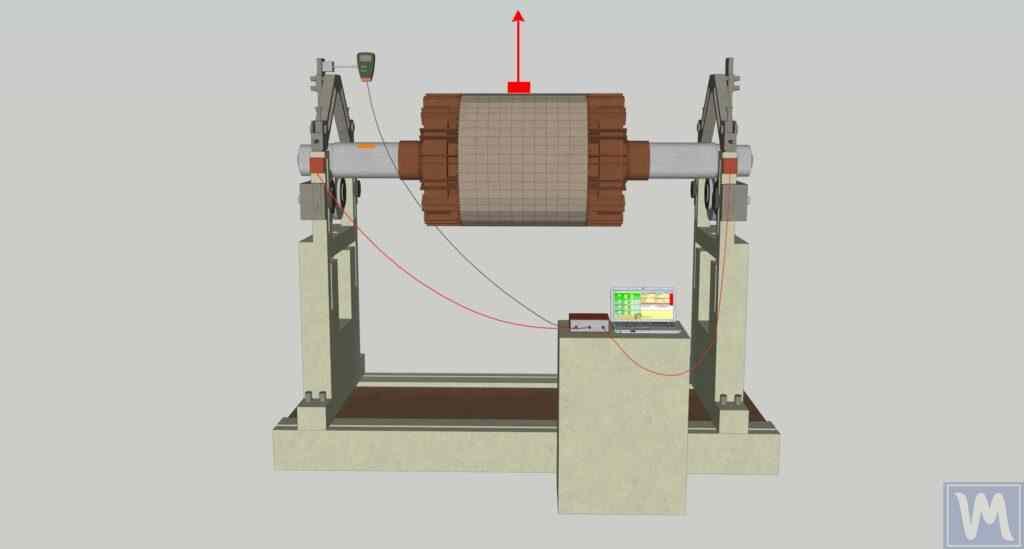

Dynamic Balancing Process Using the Balanset-1A Device

So, what does dynamic balancing look like in practice? In the field, you can use a portable balancing kit (like the Balanset-1A) to balance the rotor on your machine. Below is an overview of the step-by-step process:

- Mount the sensors: Install vibration sensors at both ends of the rotor, as close to the bearing supports as possible. Each sensor should be oriented perpendicular to the rotor's axis (to measure the radial vibration).

- Attach a reflective marker: Stick a small piece of reflective tape or a similar marker onto the rotor. This will be used by the tachometer to measure rotational speed and phase.

- Set up the laser tachometer: Place the photo-tachometer on a magnetic base and position it so that its laser beam can detect the reflective marker on each revolution.

- Connect the hardware: Plug the vibration sensors into the balancing device (e.g., the Balanset-1A unit). Connect the device to a laptop running the balancing software.

- Configure the software: Launch the balancing program and select the option for balancing in two planes (two-plane dynamic balancing is required for long rotors).

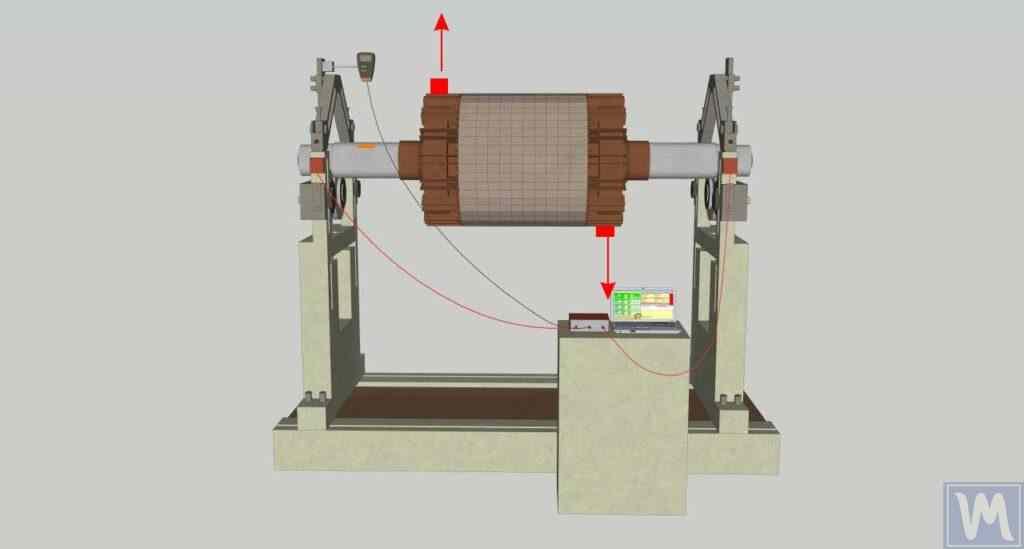

- Input calibration weight: Weigh a small trial weight that will be used for calibration. Enter its exact weight and the radius at which you will attach it.

- Take initial readings: Start the rotor and let it spin at operating speed. The sensors measure the initial vibration magnitude and phase angle at each end.

- Attach trial weight on Plane 1: Stop the rotor. Secure the calibration (trial) weight to the rotor on the first plane. Mark the exact angular position.

- Measure vibration with trial weight: Run the rotor again with the trial weight attached. Make sure you get a significant change (at least ~20% change in vibration amplitude).

- Move trial weight to Plane 2: Stop the rotor and move the same trial weight to the second plane (near the other end).

- Measure again on Plane 2: Start the rotor with the trial weight in the second plane and record the vibration readings.

- Calculate corrective weights: The software will compute the exact weight needed to counterbalance the rotor on each plane and the precise angle where each weight should be placed.

- Remove trial weight: Stop the rotor. Crucial Step: Remove the calibration (trial) weight before attaching the final corrective weights.

- Apply compensating weights: Prepare the actual compensating weights as recommended by the software. Weld or firmly attach these weights onto the rotor at the indicated positions.

- Test the balance: Finally, run the rotor one more time to check the vibration levels. Once the readings show vibration is within acceptable limits (e.g., under 4.5 mm/s), the rotor is successfully balanced.

Hooray, our flail mower's rotor is balanced! The machine should now run much more smoothly, with minimal vibration.

Why Is My Flail Mower Still Vibrating After Balancing?

Sometimes, even after going through the balancing process, a rotor might still vibrate. If your flail mower is still vibrating after you've attempted to balance the rotor, it's likely due to: mechanical issues with the machine, improper conditions during the balancing process, or errors in how the balancing was done.

Mechanical Issues That Can Prevent Balancing

- Missing or damaged flails: Ensure that all flail blades or hammers are present, properly attached, and in similar condition. Always replace flails in sets to keep the rotor balanced.

- Damaged or worn bearings: If the rotor's bearings are worn out, have too much play, or are damaged, the rotor won't spin true. Any balancing effort will be futile until the bearings are in good shape.

- Bent shaft: If the rotor's shaft is bent, no amount of weight adjustment will fix the vibration. A bent rotor needs to be straightened or replaced.

- Loose mounting points: Check the attachment points of the flail mower or mulcher. If bolts are loose or mounting brackets are worn, the whole machine might shake.

- Rotor striking other parts: Make sure the rotor isn't brushing against any stationary part of the machine.

- Cracks in the mower body: If the mower's structure is cracked, the rotor's vibrations can resonate and amplify. Such cracks need to be repaired first.

- Debris inside the rotor: Sometimes material can accumulate inside a hollow rotor drum. Clean out the inside of the rotor before attempting to balance.

Improper Balancing Conditions

- Resonance issues: If the rotor's operating speed is at or near a natural resonant frequency of the machine, even a small imbalance can cause disproportionately large vibrations.

- Changing conditions mid-process: The machine's condition during balancing should remain consistent. Always keep conditions the same for all measurement runs.

- Uneven speed or throttle: Try to run the rotor at the same RPM for each measurement. Large fluctuations in speed between runs can make the vibration data inconsistent.

Common Mistakes in Using the Balancing Device

- Sensor mounting errors: Attach the vibration sensors securely on a clean, flat surface of the machine.

- Tachometer misalignment: If the laser tachometer moves or shifts during the process, the phase readings will be off. Secure it in place.

- Angle calculation mistakes: Always measure the angle in the direction of rotation from the reference point.

- Trial weight too light: If the trial weight is too small, it might not cause a noticeable change in vibration. Use a heavier trial weight if needed.

- Interference with the tachometer sensor: Bright sunlight can interfere with an optical tachometer's ability to detect the marker. Shade the sensor if needed.

Frequently Asked Questions

How do I know if my flail mower rotor is unbalanced?

Excessive vibration is the biggest clue. Other warning signs include unusual rattling noises, bearings wearing out or failing much faster than normal, bolts and fasteners constantly coming loose, cracks appearing in the mower's frame, or even feeling the vibration carry through to the tractor. If you notice a combination of these, your rotor is likely unbalanced.

Can I balance a flail mower rotor without a balancing machine?

You can correct a simple static imbalance yourself (by counter-weighting the heavy side of the rotor until it stays level). However, you cannot fix a dynamic imbalance without specialized equipment. Long flail mower rotors usually have dynamic imbalance that only a proper dynamic balancer can detect and correct.

How do you dynamically balance a flail mower rotor?

Dynamic balancing requires a special tool or machine. In practice, you attach sensors to the machine, use a laser tachometer to track the rotor's rotation, add a test weight to see how it affects the vibration, and then calculate where to weld on permanent counterweights to cancel out the imbalance. A device like the Balanset-1A helps automate these measurements and calculations.

What happens if I run a flail mower with an unbalanced rotor?

The machine will be subjected to intense, harmful vibration the entire time it's running. That vibration will cause parts to wear out much faster – for example, bearings may fail repeatedly, and bolts or other components can loosen or break off. Over time, the stress can crack metal parts of the mower or even damage the tractor. In short, running with an unbalanced rotor drastically shortens your equipment's lifespan and can lead to sudden, expensive breakdowns.

Conclusion

Dynamic balancing of flail mower and forestry mulcher rotors is a critical maintenance task to ensure smooth and safe operation. By identifying whether your rotor's imbalance is static or dynamic and using the proper equipment to address it, you can eliminate destructive vibrations and all the problems they cause. With a balanced rotor, your equipment will experience less wear, your bearings and other components will last longer, and you'll reduce the risk of unexpected breakdowns and safety hazards.

Always remember to address any mechanical issues (like bad bearings or missing blades) before attempting to balance, and follow the proper procedure closely. If done correctly, dynamic balancing can dramatically improve your mower's performance. Many operators find that after balancing, the machine runs "like new"—no more rattling, no more excessive vibration, and no more frequent repairs.

Ready to reduce your flail mower's vibration and save on repair costs? Consider using a portable dynamic balancer like the Balanset-1A to tune your rotor in the field. If you have questions or need expert help, feel free to reach out to us—we're here to help you get the most out of your equipment.

View Balanset-1A →

0 Comments